Tungsten Containing Mesoporous Materials Preparation Process

- Details

- Category: Tungsten Information

- Published on Sunday, 11 November 2018 20:10

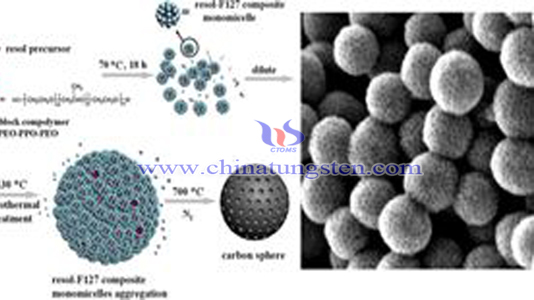

Tungsten containing mesoporous materials have nano-scale homogeneous pore structure and huge surface area. They are a good catalyst carrier. By introducing active components into mesoporous materials, they can provide the active sites needed for catalytic reaction. They have shape-selective catalytic properties and are typical micro-reactor.

Most mesoporous materials do not possess catalytic functions or exhibit special catalytic functions. However, the introduction of active components into mesoporous materials can catalyze them. The introduction of tungsten as the active component of the catalyst can be carried out by impregnation or skeleton. When the active component is introduced into the skeleton of mesoporous materials, its dispersion performance is better and the catalytic atomic efficiency is higher.

The preparation process of tungsten-containing mesoporous materials is as follows: 1. Weigh 25 grams of dodecylamine (DDA) in beaker, add 150 ml absolute ethanol and 1300 ml ionic water, stir at room temperature, make dodecylamine completely dissolved, and prepare solution A. 2. Take another beaker and weigh 104 g TEOS. Under strong stirring at room temperature, add a solution consisting of 2.8 g ammonium metatungstate, 50 ml deionized water and 10 ml hydrogen peroxide. When the addition is completed, form solution B. 3. Under stirring at room temperature, solution B is added to solution A, and after dripping, it is stirred at room temperature for 24 hours; after centrifugal separation, solid samples are washed three times with deionized water, and the samples are dried at 60 C to obtain tungsten-containing mesoporous silica molecular sieves.

After the tungsten-containing silica mesoporous molecular sieves prepared by the above scheme are made into catalysts, the catalysts can be used in olefin disproportionation reactions, such as butene disproportionation reactions to propylene. The disproportionation reaction of butene-1 was carried out in a fixed-bed reactor with reaction temperature ranging from 0 to 550 ℃, reaction pressure ranging from 0 to 10 MPa and liquid space velocity ranging from 0.1 to 3 hours-1.

Since the tungsten component is directly introduced into the HMS mesoporous molecular sieve framework, since the molecular sieve has a large specific surface area and a single pore, the catalyst has good catalytic activity for the disproportionation reaction of butene, and the butene double bond isomerized. The activity was inhibited, the selectivity of ethylene and hexene was improved, and good technical results were obtained. Compared with the conventional WO3/SiO2 catalyst, WOX/HMS was used as a catalyst for the disprotonation reaction of butene-1, and the selectivity of ethylene and hexene in the product was increased from 1.87% to 8.75% to 14.66%; in the product, C4=-2/ A decrease in the C4 = -1 ratio indicates that the double bond isomerization of butene-1 is inhibited.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com