Tungsten Nitride-based Ternary Nanocomposite Superhard Film Material

- Details

- Category: Tungsten Information

- Published on Sunday, 11 November 2018 19:40

With the development of society, the requirement for materials is higher and higher. In some application fields, materials are required not only to have flexibility and strength, but also to have certain hardness and wear resistance, such as cutting tools in mechanical processing, drills for deep energy exploration, dies used in mechanical manufacturing and cylinder block of engine, etc.. For this reason, people try to use surface modification technology and surface coating technology to not only maintain the high strength and toughness of the material matrix, but also give play to the advantages of super-hard, super-strong and wear-resistant surface coating, thus greatly improving the durability and adaptability of the material.

In order to meet the requirements of material properties, some scholars have proposed a tungsten nitride-based ternary nanocomposite superhard film material with high hardness and strong adhesion between film and substrate. The technical scheme adopted is as follows: tungsten nitride-based ternary nanocomposite superhard film materials include substrates, in particular, the substrates are covered with nanocomposite superhard films of chemical formula WxM1-xN. W in the chemical formula WxM1-xN is tungsten, M is titanium, tantalum or chromium, N is nitrogen and x, and the values range from 0.06 to 0.72. The nanocomposite superhard film consists of tungsten nitride solid solution phase and tungsten metal phase of tungsten and metal M, or tungsten nitride phase, tungsten metal phase and metal M phase. The grain size of the nanocomposite superhard film is 4-30 nm, and the thickness of the film is 3-7 um. The preparation process is as follows:

Step 1: Place the composite target and base consisting of tungsten metal and metal substitutes on the cathode and the sample table in the vacuum chamber of magnetron sputtering equipment, respectively. The area ratio of tungsten metal to metal substitutes in the composite target is 2:1, the distance between the composite target and the base is 50 mm, the metal substitutes are tantalum and the base is stainless steel. The substrate is polished, cleaned and dried before it is placed in the sample table in the vacuum chamber of the magnetron sputtering equipment.

Step 2: After the vacuum chamber has a vacuum degree of 1 *10-3 PA and the base temperature reaches 350 ℃, the vacuum chamber is sputtered in a mixture atmosphere of argon and nitrogen for 120 minutes, in which, before the vacuum chamber is in a mixture atmosphere of argon and nitrogen, argon is injected into the vacuum chamber and pre-sputtered for 20 minutes. Then nitrogen is injected into the vacuum chamber. The flow ratio between argon and nitrogen is 1:1, the working pressure is 0.5Pa, and the sputtering power is 80W. After sputtering, the heating of the substrate is stopped, the mixture of argon and nitrogen is closed, and the vacuum of the molecular pump is maintained. After the temperature of the substrate is 80 ℃, the vacuum is stopped, and the natural vacuum is cooled. Tungsten nitride based three element nanocomposite superhard thin films were prepared at room temperature.

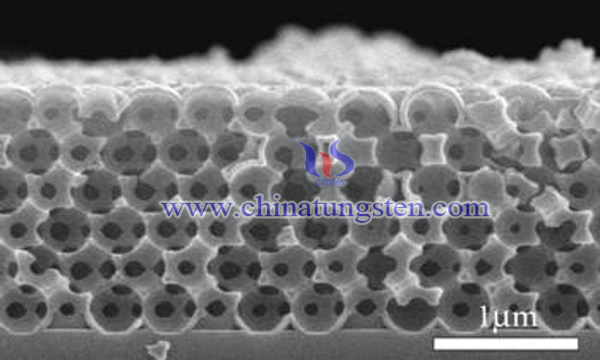

The prepared tungsten nitride-based ternary nanocomposite superhard films were characterized by field emission scanning electron microscopy (FESEM) and X-ray diffraction (XRD). The results show that the superhard films are compact, free of holes and cracks. The thickness of the films is 3-7 um. The nanoindentation instrument and scratches are used for the prepared tungsten nitride-based ternary nanocomposite superhard films. After testing by instrument and friction and wear tester, it can be seen that the hardness of superhard film is greater than 40GPa, the bonding force between film and substrate is greater than 50N, and the friction coefficient is less than 0.4. The preparation method is simple and easy to operate, the deposition rate is fast, the efficiency is high, and the production cost is low. It is suitable for high-speed steel tools and cemented carbide tools. And other wear-resistant tools, which are suitable for large-scale industrial production.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com