Lathe for Tungsten Carbide Die

- Details

- Category: Tungsten Information

- Published on Sunday, 13 May 2018 18:10

In the production process, the surface of the tungsten carbide die needs to be machined by turning tool. At present, the lathe sold on the market can only process a mould, of which the machining efficiency is low.

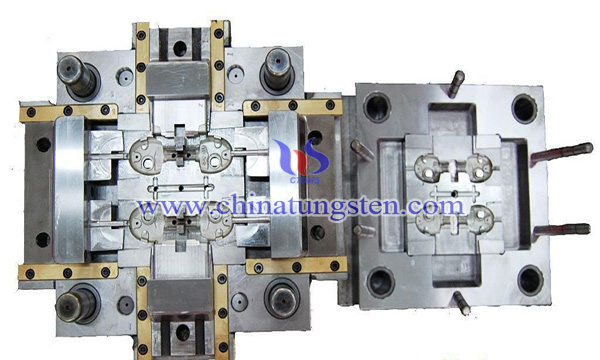

To solve the above technical problems, some scholars have designed a lathe which can machine two kinds of tungsten carbide die simultaneously. The technical scheme adopted by the utility model is as follows:

1, The first cylinder is mounted on the first sliding guide and the end of the piston rod is connected with the first splint.

2, The second cylinder is mounted on the second slide guide and the end of the piston rod is connected with the second splint.

3, The third cylinder is mounted on the third slide guide and the end of the piston rod is connected with the third splint.

4, The fourth cylinder is mounted on the fourth slide guide and the end of the piston rod is connected with the fourth splint.

One end of the lathe tool is connected with the first turning roller, and the other end is connected with the second turning rollers. Motor and belt are also included. The end of the second turning roller is connected by the second bearing and connected by the moving wheel. The motor is connected with the drive wheel, which should be driven through a belt through a moving wheel and an active wheel.

Advantage Analysis:

Given that two tungsten carbide dies can be processed at the same time, the processing efficiency is high. Movement of cylinders is convenient. The splint is capable of expansion and contraction and the degree of automation is high. Fourth, the turning of the lathe tool is convenient. Fifth, the driving wheel revolves through the motor, and the drive wheel drives the driven wheel to rotate through the belt drive. By driving the second turning wheel from the moving wheel to rotate the roller, then the EMU knife is rotated. As a result, the transmission structure is simple.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com