Ammonium Paratungstate Crystallization Mother Liquor Optimization Recycle Method

- Details

- Category: Tungsten Information

- Published on Sunday, 13 May 2018 20:55

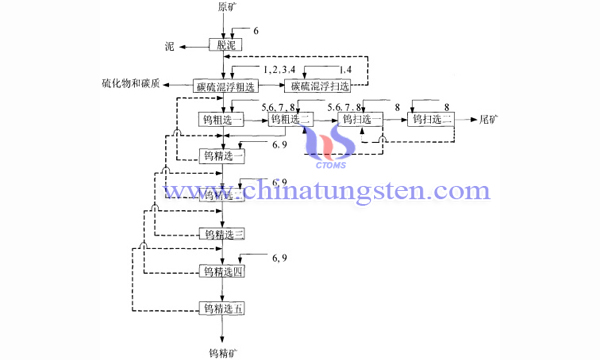

Ammonium paratungstate(APT) is an important tungsten product, mainly used in the manufacture of tungsten trioxide or blue tungsten oxide. At present, the production process of APT products is mainly based on alkali method. Tungsten concentrates or Scheelite Concentrate are extracted and prepared by high pressure alkali boiling and soda pressing. Then, the solution of ammonium tungstate is prepared by solvent extraction or ion exchange method. Finally, the APT product is prepared by evaporation crystallization of ammonium tungstate solution; acid process technology is used. The Scheelite Concentrate is decomposed by hydrochloric acid, dissolved in ammonia, and then evaporated and crystallized to produce APT products.

The evaporation crystallization of ammonium tungstate solution is a necessary step in the preparation of APT products. In the process of evaporation crystallization, a large amount of ammonia vapor and crystalline mother liquid are produced. According to the actual production conditions, it is difficult to realize recycling, not only causes the waste of ammonia and tungsten resources, but also forms a serious pollution of ammonia and heavy metals.

In order to solve the problems of high cost of acid and alkali consumption, high ammonia nitrogen, high requirement for equipment and low concentration of ammonia in ammonia steam recovery, a comprehensive utilization method of tungsten crystallization mother liquid and ammonia vapor is used to convert WO3 into extremely insoluble calcium tungstate. In the process of recovery, the ammonia containing steam is directly separated from the condenser and directly enters the distillation column for concentration treatment, and the process for recovering ammonia or ammonium chloride is mainly carried out.

The WO3 content of APT is 32.5g/L, and the calcium oxide is added to the crystal mother liquor by 1.5 times the theory, and the mixed solution is mixed with the pump into the plate frame pressure filter for pressure filtration. The solid phase after the filtration is further treated back to WO3 by the calcium tungstate product. After the filtration, the liquid is heated by steam and heated. The solid phase is recycled by calcium chloride for further treatment, and the liquid phase after heating is ammonia vapor.

Ammonia vapor containing ammonium tungstate evaporated and crystallized in the process of producing ammonium para tungstate (APT) product was mixed into the plate tower through a mixture of pipes. The operating pressure in the tower was 0.1MPa. The ammonia vapor in the tower was concentrated in the plate tower; the steam of the top of the tower was mixed with ammonia and water, and the steam was recovered by hydrochloric acid to be the product of ammonium chloride; the bottom drainage of the tower was drained. Ammonia concentration of ammonia nitrogen concentration of less than 15mg/L, can be discharged or used for production.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com