Tungsten Carbide Dies for Multichannel Aluminum Flat Tube

- Details

- Category: Tungsten Information

- Published on Sunday, 13 May 2018 18:05

Tungsten carbide dies for multichannel aluminum flat tube have long service life, while their structures are complex and difficult to manufacture. They are made of cemented carbide materials. At present, many difficulties in mould manufacturing technology and equipment have been overcome, and a relatively complete manufacturing process of continuous extrusion die has been formed, which provides qualified mould for continuous extrusion line.

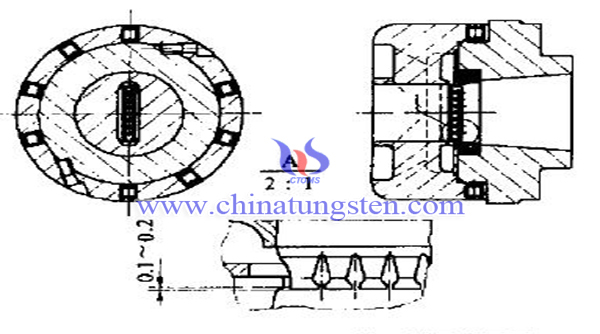

Gap between the patrix and the mold unloading is 0.5 nm. The two direction adjustment screws and eight adjusting screws are adjusted and fastened to control the relative position of the core rod and the shape hole, so that the thickness of the hole wall is uniform. R300 cambered surface and export band in the mold hole population can be processed by EDM process.

As the die piece is made of tungsten carbide which has many carbides, poor conductivity and thermal conductivity, the phenomenon of frequent arcing and high electrode loss will occur during machining, making it difficult to remove electrical machining. The choice of tungsten copper alloy as EDM electrode and reasonable selection of electrical parameters will greatly improve the above phenomenon.

When heated to 550 ~600℃, the upper and lower mold sleeve will respectively assembly with mold core and die sheet. And the protruding amount of the mold core is about 0.1 ~0.2 mm controlled with restricted fetal gear. Finally, it is time to assemble the upper and lower die while adjust the die hole with screws to make the wall thickness uniform.

In view of the difficulties in machining, a feasible tungsten carbide die can be produced by adopting practical machining methods. The whole development process realizes the split processing of the mould, which provides conditions for the standardization of the die. If this technology can be applied in ordinary extrusion die processing, it will speed up the development of die manufacturing technology.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com