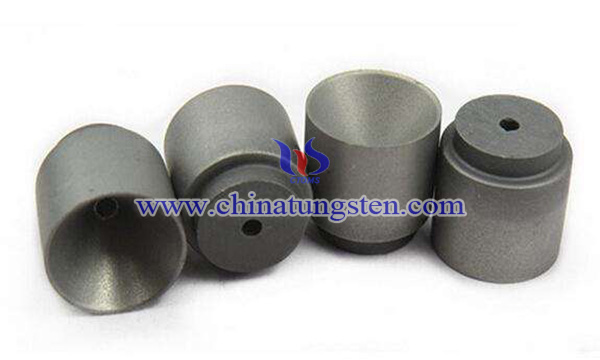

Microstructural Tungsten Carbide Dies

- Details

- Category: Tungsten Information

- Published on Sunday, 06 May 2018 19:45

Nowadays, quartz glass materials are widely used for their optical properties because of their micro structural design. However, because of its hard-brittle materials, only mechanical processing is needed to process the plastic domain to ensure its transparency and mirror effect. The processing time of the plastic field is very long and does not meet the needs of the actual production of quartz glass optical elements. It is urgent to use a kind of technology to promote the properties of the optical elements of quartz glass.

As a micro molding process, hot press micromolding has a series of advantages, such as good geometry, size adaptability, low cost, high efficiency, continuous and automatic production. And it is an important development direction for large-scale manufacture of micro and small products. Presently, the commonly used method of micro mold production is the combination of MEMS process and electroforming. The fabrication of microstructures by photolithography and plasma etching has the advantage of high accuracy and mass production. But the equipment is expensive, the mechanical strength of mold is low, and the life span is short.

On the basis of the original processing, a microstructural cemented carbide die was designed and developed, including the cemented carbide core with micro groove. The micro groove array was arranged on the machining surface of the cemented carbide core with micro groove, and the micro groove array was used to form the microstructure on the finished product after hot pressing.

Further, the tungsten carbide die core with a micro groove is a kind of die core with a curved surface with a curved surface with a curved surface. The micro groove array is arranged on the surface parallel to the surface, and the machining surface is set to a curved surface. Its purpose is to make use of the good optical properties of the quartz glass and to print through the micro groove core. On the quartz glass, the concave micro groove quartz glass is formed. Compared with the current ordinary quartz glass plate, it has the characteristics of higher light conduction efficiency, higher brightness and more uniform luminescence, and the optical properties are increased.

Advantages of A New Microstructural Tungsten Carbide Die:

1, Compared with the common hot pressing mould, the hot-pressing microstructural tungsten carbide die is controlled by the parameters such as temperature, pressure, holding time, vacuuming and so on. Accurating hot pressing micro forming conditions and determining the parameter range of high precision forming can ensure the surface quality of quartz glass workpiece, which can help to realize large-scale manufacturing and laboratory technology research.

2, Diamond wheels can be made on the surface of the workpiece to make micro structures with specific shape. Compared with lithography and etching processing methods, the equipment is low in cost and simple in technology. And diamond grinding wheel can form material with high hardness.

3, The workpiece has smooth surface and high accuracy.

4, Plane or surface can be set in the hot-pressing machining surface. The micro groove structure of the surface can drive quartz glass in order to reduce the pressure load of hot pressing and improve the forming accuracy and consistency of the microstructure.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com