High Density Tungsten Alloy Improvement

- Details

- Category: Tungsten Information

- Published on Monday, 05 February 2018 13:39

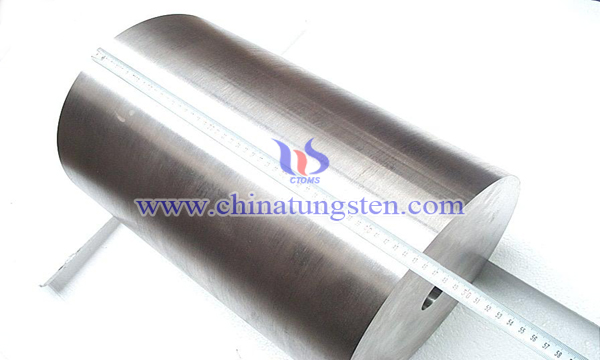

High density tungsten alloy is a kind of tungsten based (mass fraction of tungsten or tungsten content is usually 80% ~ 97%), and adding Ni, Fe, Co, Cu, Mo, Cr and other elements and the composition of the alloy, its density is as high as 16.5 ~ 19.0g/cm3, which had been known as high density tungsten alloy high proportion tungsten alloy, heavy alloy.

The existing production processes for high-density tungsten alloys, or high-density tungsten alloys, are mixing, cold isostatic pressing, sintering and vacuum annealing. However, tungsten alloys produced by the above process all have defects of poor toughness and low hardness. Taking 95WNiFe alloy containing 95% of tungsten and 97WNiFe alloy containing 97% of tungsten as examples, the impact toughness of the 95WNiFe alloy is ≦ 0.27MJ / m2 and the Rockwell hardness value is ≦ 25HRC, and the impact toughness of the 97WNiFe alloy is ≦ 0.10MJ / m2 and its Rockwell hardness value ≤ 28HRC.

In view of the shortcomings of the above existing technologies, some scholars have proposed corresponding improvements.

1. Mixing: according to the final requirement, we made the composition requirement of high-density tungsten alloy. We put all kinds of metal powder mixed into the tilting mixer at the same time, and mixed them in the tilting mixer for 6~8 hours to get the mixed powder fully mixed. The tilt angle of the inclined mixer is 9~13 degrees and the speed is 20 ~ 34rpm.

2. Cold isostatic pressing: the conventional cold isostatic pressing technology is used to compacted the mixture powder which is fully mixed and then the pressure is 120 to 170Mpa, and the pressing time is 1 to 6min, and the powder compact is made.

3. Sintering: the prepared powder compact is placed in a high-temperature sintering furnace and under the protection of ammonia decomposition gas or hydrogen to obtain a uniform tungsten alloy sintered billet having a sintering temperature of 1400-1600 DEG C and sintering holding time is 30 ~ 90min, the ammonia decomposition gas or hydrogen flow rate of 1 ~ 4m3 / h;

4. Quenching: the prepared tungsten alloy sintered in high temperature quenching furnace for quenching and divided into two consecutive phases, the first phase of the quenching temperature is 1100~1500 DEG C and the holding time is 10 ~ 50min, second phase quenching temperature is 25~80 DEG C and the holding time is 30 ~ 40min;

5. Vacuum annealing: the sintered tungsten alloy quenched in high temperature vacuum furnace for vacuum annealing, the high vacuum degree of vacuum is not less than 10-1Pa, the annealing temperature is 1100~1300 DEG C and the annealing time is 1 ~ 4h, to complete the whole process of high density tungsten alloy.

The tungsten heavy alloy made by the improved method has the advantages of simple production process, simple operation and high quality tungsten alloy. It can effectively improve the mechanical properties of high-density tungsten alloy.

- Tungsten Alloy Manufacturer & Supplier, Chinatungsten Online: www.tungsten-alloy.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com