Preparation of Pyrochlore-Type Tungsten Oxide in Hydrothermal Method

- Details

- Category: Tungsten Information

- Published on Monday, 05 February 2018 12:17

Pyrochlore-type tungsten oxide take twisted WO6-octahedrons as the structural unit, through the angular point of W-O rigid skeleton to form a layered structure with a circular hole. Due to its special physical and chemical properties, it is widely used in the fields of catalysis, sensing, electronics and other materials science.

The preparation methods of pyrochlore-type tungsten oxide generally adopt soft-chemical synthesis and hydrothermal method. Hydrothermal method of pyrochlore-type tungsten oxide is the most-commonly-used method. Many domestic scholars’ preparation and study of pyrochlore-type tungsten oxide are also more concentrated in the improvement of hydrothermal method.

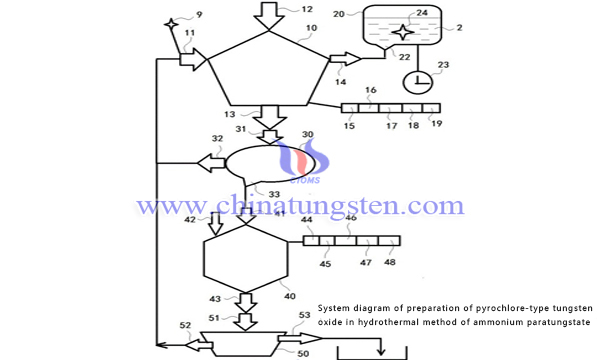

Some scholars have proposed a system for the hydrothermal conversion of pyrochlore-type tungsten oxide by the ammonium-paratungstate hydrothermal system. The system includes: an ammonium-paratungstate conversion vessel, a gas-release absorber, a material-reforming purification device, and a transition filter and so on, the operation process is as follows:

Take ammonium paratungstate (APT · nH2O) solid and ammonium-sulfate solution with a mass concentration of 200g / L, the liquid to solid ratio is 5: 1, placed in a closed micro-hydrothermal reactor. Stirring strength set to 400 rev / min, and the reaction is at 140 ℃ for 4 hours during the process the gas was emitted for several times. The quantity of ammonia is 0.5 times of the quantity of ammonia of added ammonium paratungstate, and it is filtered to obtain the transformed material. Diffraction analysis of X-ray showed that the phases were WO3 · 0.5H2O and trace 5 (NH4) 2O · 12WO3 · 5H2O.

Take the transition material and deionized water, and the liquid to solid ratio is 10: 1 which is placed in a beaker. Maintain the temperature in 70 ° C, magnetic stirring for 2 hours. Intensity of stirring set to 1000 rev / min, filtered and dried to obtain the final product. It shows in the X-ray that the phase is WO3 · 0.5H2O. The reaction rate is 88.6%.

Based on the utility model, and adopt the hydrothermal method to prepare the product, and based on the difference of solution to obtain the pyrochlore-type tungsten oxide with different impurities, and the quantity of impurity can be controlled. Compared with other products prepared by hydrothermal method taking sodium-tungstate solution as raw-material, it can exclude the interference of impurities of Na. Among them, WO3 · 0.5H2O of ammonium-type can also be used to prepare ultrafine WO3 powder with the reaction rate of more than 99%. Reagents used are easily to get and can be recycled. The gas is easily to be recycled. No pollutants and environmentally-friendly. The equipment is simple and handy to operate.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com