Thermodynamic Problems of Sintering

- Details

- Category: Tungsten Information

- Published on Wednesday, 31 January 2018 22:11

The sintering process of tungsten carbide has a spontaneous trend. On the one hand, the powder itself has the tendency of automatic bonding or agglomeration. Especially, the very fine powder, even at room temperature, will coalesces gradually for a long time. On the other hand, this trend will be more obvious at high sintering temperatures.

From the viewpoint of thermodynamics, this is the process that the free energy of system decreases (the powder does work to the environment). Namely, the sintered body is in a state of low energy relative to the powder body under certain conditions, and the free energy of the system always decreases with the sintering process.

The reduction of the free energy of the sintering system is the driving force of the sintering process. It includes the following aspects.

1, Because of the increase of the particle binding surface (the sintered neck) and the flatness of

the particle surface, the total surface area of the powder is reduced and the free energy of the total surface decreases.

2, The total volume and total surface area of the pores in the sintered body are reduced.

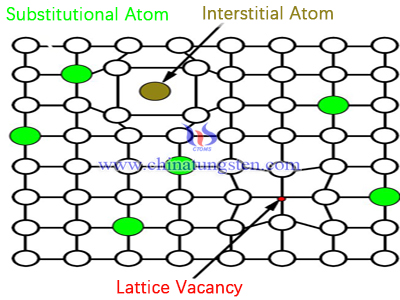

3, Elimination of lattice distortion in powder particles.

Driving forces of 1 and 2 are the excess surface energy in the block before sintering. And the 3 is the lattice distortion energy in the block. There is an increase in energy caused by excess vacancy, dislocation and internal stress. A certain amount of heat balance vacancies, vacancy clusters and dislocation networks are retained in the sintered body. The absolute value of lattice distortion in sintering process is still secondary to the decrease of surface energy, and the most important factor is surface energy.

The thermodynamic formula: ΔG=ΔH-TΔS(1)

Where: ΔG … the change of free energy of the sintered body,

ΔH … the change of enthalpy of the sintered body,

ΔS … system entropy change,

T … temperature of the system.

According to the change of enthalpy before and after sintering, the driving force of sintering can be estimated. The interfacial transition of particles into crystal interface after sintering. As the grain boundary can be lower, the total energy is still reduced. During the sintering progress, the grain boundaries at the neck of sintering can move to the particles on both sides, and the original grain boundaries in the particles may also migrate and decrease through recrystallization or polycrystalline growth.

Therefore, further reduction of grain boundary energy is the main driving force for sintering neck formation and sintering. When sintering grain strength is further increased, sintered body density and other properties will further improve.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com