Sintering Process: Change of Powder

- Details

- Category: Tungsten Information

- Published on Wednesday, 31 January 2018 22:14

Sintering process of tungsten carbide is carried out by the contact between the powder and the migration of the atoms. At high temperatures, the caking is more obvious. The phenomenon that the powder is heated while the particles are bonded between them is so called the sintering.

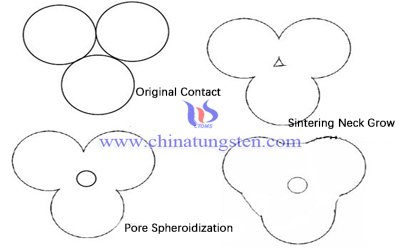

According to time, the isothermal sintering process of powder can be roughly divided into three stages, such as bonding stage, growing stage of the sinter neck, closed pore spheroidization and shrinkage stage.

1, Bonding Stage

At the initial stage, the bonding strength between particles increases, that is, the gravitational attraction between atoms on the joint surface. In powder or powder press, the number of atoms that can reach the scope of atomic gravitation on the surface of the particles is limited. The original contact point or surface between particles is converted into crystal binding, that is, the formation of the cervix through the atomic process, such as nucleation, crystallization and growth.

In this stage, the grain particles within the particle shape does not change, basically unchanged, the sintered body does not shrink, but also increase the density of small, sinter strength and conductivity due to particle binding surface is increased and significantly increased.

2, Growing Stage of The Sinter Neck

The shrinkage of the sintered body, the increase of density and strength is the main feature of this stage. At high temperature, due to the increase of the amplitude of atomic vibration and diffusion, more atoms enter the range of the atomic force and form the bonding surface. And the strength of the sintered body increases with the enlargement of the bonding surface.

The large migration of atoms to the particle binding surface makes the sintered neck expand, the distance between the particles is reduced, the growing stage of the sintered neck is small, and a continuous pore network is formed. At the same time, due to the growth of grain, the grain boundary over the pores moved, and the pores were swept away by the grain boundary, and the pores disappeared.

3, Closed Pore Spheroidization and Shrinkage Stage

With the growth of the sintered neck, the original interconnected pores between the particles gradually shrink into the obturator and then gradually become round. While the properties and shapes of the pores change, the size and quantity of the pores are also changing. Once the density of the sintered body reaches 90%, most of the pores are completely separated, the number of closed holes increases greatly, and the shape of the pores tends to be spherical and decreases.

At this stage, the whole sintering body can still shrink slowly, which is realized mainly by the disappearance of the small holes and the decrease of the number of pores. This stage can last for a long time, but still a small amount of isolated small pores cannot be eliminated.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com