Tungsten Copper Alloy Casting Method Preparation

- Details

- Category: Tungsten Information

- Published on Sunday, 07 January 2018 21:36

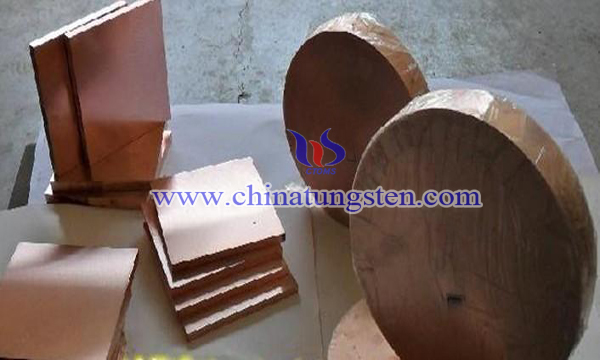

Tungsten copper alloy composite material combines the advantages of two kinds of elements W and Cu, has low thermal expansion coefficient, good conductivity, good thermal conductivity and good arc erosion resistance, in mechanical processing, electrical engineering and electronic information field is widely used as electrical contact materials, electrode materials and electronic packaging materials.

The main methods for preparing tungsten copper plates or sheets are metal powder rolling, plasma spraying - rolling, elemental powder method and physical gas phase deposition. In the process of preparation, these methods still have some limitations and shortcomings. Because of the hard control of squeeze angle, metal powder rolling is often difficult to obtain ideal rolling parts. There are oxides in the alloy sheet produced by plasma spraying and rolling, and the uniformity of microstructure needs to be improved. Elemental powder preparation process is easy to introduce high impurity content and defect density is difficult to achieve full densification. The low output of physical vapor deposition is difficult to achieve industrial mass production.

Tape casting process is a resin sheet extruded by extruder and extruded through the slot die, so that the melt is tightly attached to the cooling roller, and the sheet is made through stretching, trimming and coiling. The method of preparation of tungsten copper sheet or plate by casting method is made, and copper clad tungsten composite powder is selected as raw material to prepare casting slurry, then the tungsten copper sheet or plate can be obtained by casting, sintering, pressing, sintering and surface treatment.

Copper and tungsten composite powders are selected as raw materials, which can solve the problem of copper segregation in the process of powder sintering and make copper uniformly distributed around the tungsten matrix. It fundamentally avoids the difficulty of controlling the uniformity of mixture in traditional powder metallurgy process, and lays a solid foundation for subsequent infiltration and sintering, and even the final homogeneity of tungsten copper sheet.

- Tungsten Alloy Manufacturer & Supplier, Chinatungsten Online: www.tungsten-alloy.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com