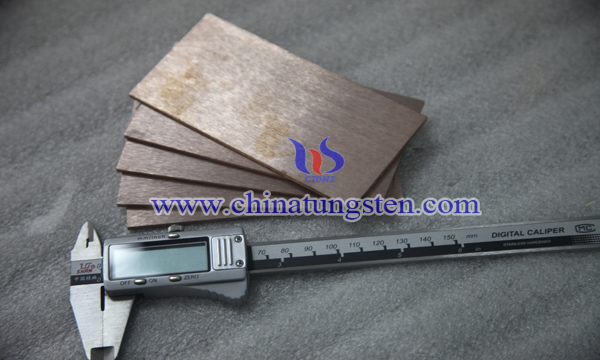

Tungsten Copper Gradient Heat Sink Material

- Details

- Category: Tungsten Information

- Published on Thursday, 04 January 2018 16:58

With the high power of electronic components and more stringent working conditions, the uniform W-Cu heat sink material is difficult to meet the requirements of heat dissipation. Therefore, it is considered to be an effective way to solve this problem by developing the tungsten copper heat sink material which is formed along the thickness direction.

The design of tungsten copper gradient heat sink is mostly based on the principle of reverse design. First, the actual structure and working conditions of the material are determined. Based on these information, we choose the transition performance and microstructure, as well as the preparation and evaluation methods. After determining the composition of each layer, the theoretical density, volume modulus, thermal conductivity and thermal expansion coefficient of the gradient layers can be obtained according to the Kern mixing rule.

Infiltration method is one of the most used methods. It generally uses porous W powder with different granularity to suppress and sintering porous media with gradient distribution. Then W-Cu gradient functional material is obtained by infiltrating copper. The gradient W framework is the key to the preparation of W-Cu functionally graded materials.

Plasma spraying is to use plasma arc generator to heat and ionize the gas in the nozzle, form high temperature and high speed plasma jet, melt and atomize metal or non-metallic materials, and spray it to the coating on the surface of pretreated workpiece at high speed.

The laminate powder metallurgy method is based on the obvious melting point and resistivity difference of W and Cu. Under the condition of ultra-high pressure, the W-Cu gradient functionally material with relatively high density has been prepared by electrifying, rapid pressing and sintering.

Tungsten copper gradient heat sink material is the application of gradient function material design thought. Due to the characteristics of tungsten and copper, there are still many works to be perfected in composition design, preparation and sintering. The development of W-Cu heat sink material with variable thickness along the thickness direction has been the goal pursued by researchers. Although some methods can prepare continuous graded materials at present, they are far from enough, and more advanced preparation technologies are needed.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com