Preparation of Tungsten Copper Gradient Heat Sink Material by Infiltration Method

- Details

- Category: Tungsten Information

- Published on Thursday, 04 January 2018 16:39

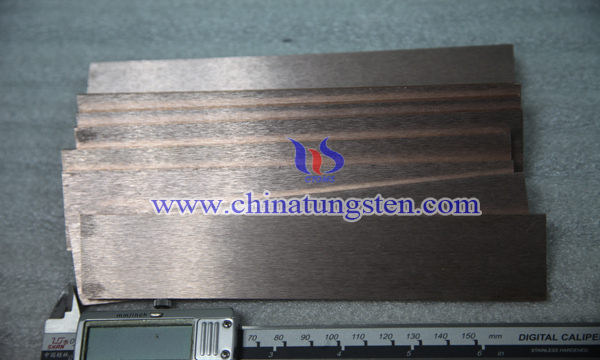

Tungsten copper composite is one of the most widely used heat sink materials at present. It is made up of high conductivity copper and refractory metal tungsten. They neither dissolve each other nor form intermetallic compounds, so they are also called pseudo alloys. Tungsten copper composites are used in large scale integrated circuits and high power microwave devices as electronic packaging materials and heat sink materials, such as substrate, connector and heat sink.

Tungsten copper heat sink gradient material is tungsten copper alloy composition changed along the thickness direction, W-Cu gradient heat sink material was designed with reverse design principle, first determine the actual structure and working conditions of materials, according to the information, select the transition composition properties and microstructure and preparation and evaluation method. After determining the composition of each layer, the theoretical density, volume modulus, thermal conductivity and thermal expansion coefficient of the gradient layers can be obtained according to the Kern mixing rule. In general, gradient heat sink material preparation principle seems easy but actually complex.

Infiltration method is one of the most common methods for the manufacture of tungsten copper composites. The tungsten copper gradient heat sink material is made by melt infiltration method. Generally, porous particles with gradient distribution are obtained by pressing different layers of tungsten powder and sintering. Then W-Cu gradient functional material is obtained by infiltrating copper.

The key process of the infiltration method is the preparation of the tungsten skeleton, in which the grain size of tungsten powder and the pressing of the blank have the role of the overall situation.

The theoretical density of the impregnation method for making ordinary heat sink materials is 97%-98%, but the gradient heat sink material is more strict in the process of infiltration. In practice, there may be copper, copper phase distribution is not uniform, easy to form a closed cell in tungsten body, copper phase can not completely fill the pores, guide to preparation materials of low thermal conductivity, and machined to remove excess metal infiltration of copper, increase the machining cost, low the rate of finished products.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com