Preparation of Steel Bond Hard Alloy

- Details

- Category: Tungsten Information

- Published on Friday, 22 December 2017 21:37

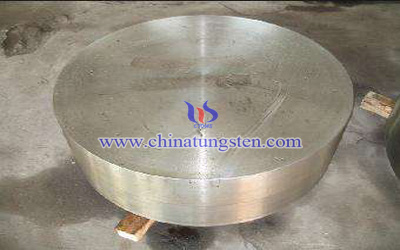

Due to the high hardness, wear resistance and good mechanical properties, steel bond hard alloy is widely used in the industry. With the development of modern technology, the traditional methods, such as melt impregnation, have been phased out. The SHS and electrometallurgy casting method appeared.

But at present, the main preparation methods in industry are still powder metallurgy and casting. According to the forming state, it also can be divided into two kinds: solid phase method and liquid phase method.

1, Solid Phase Method

1.1, Powder Metallurgy

Powder metallurgy is a common method for the production of steel bonded cemented carbide, which belongs to the solid phase method, but the method has limitations. For example, it is difficult to mix and uniform the steel matrix powder and hard phase particles, and the hard phase is not evenly distributed.

The interfacial bonding strength of the reinforced particles and the steel matrix is not high, and the products have pore, segregation, loose and bridging defects. In order to overcome these shortcomings, two ways can be made by refining the particles and using the thermal isostatic pressure.

1.2, Self-Propagating High-temperature Synthesis(SHS)

Steel bonded hard alloy prepared by this method has the advantages of simple process, short period, clean interface and high bonding strength of the interface. The process is to synthesize TiC-Fe with Fe powder, Ti powder and C as raw materials.

2, Liquid Phase Method

Liquid phase method refers to molten iron and refractory carbide particles mixed compound forming method, which mainly refers to the casting method. Sometimes, it can also be divided into stirring casting, electrometallurgy casting method.

2.1, Stirring Casting

Stirring casting is suitable for manufacture on a large scale. The process is to directly add the reinforcement particles to molten iron, so that the particles can be evenly distributed in the molten iron during high temperature diffusion process and combined with it, and then be cast into green body.

2.2, Electrometallurgy Casting

Firstly, the raw materials is put in the high frequency furnace for casting a consumable electrode, and consumable electrode melts in the furnace will. Finally, crystal is rapidly cooled. As a casting process, electrometallurgy casting is a refining process too, which can obtain high purity steel.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com