Slip Casting Technology Types

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 December 2017 17:05

The traditional tungsten carbide slip casting technology can be divided to single side casting, double-sided casting, pressure casting and vacuum casting. And the first two grouting techniques are divided according to the mold, and the latter two are divided by the grouting process.

Single Side Casting

It is also known as hollow grouting, refers to only one contact slip from the mold, plaster mold with no core grouting.

Double-Sided Casting

Double-Sided casting also known as solid casting, which refers to the contact face both sides of slurry and mold and mold core. During the formation of slurry injection mould core between the outer mold and cast at the same time, from inside and outside the two directions of water, until the body curing mold.

Pressure Casting

For huge tungsten carbide products, the time of grouting will be very long. Additionally, because the thickness of the products is thicker, when the water absorption capacity of the plaster mold is insufficient, the body is not easy to dry, and the product is not easy to form.

In order to speed up the diffusion of moisture, accelerate the speed of moisture absorption, shorten the time of grouting, and prevent the defects of grouting and defects in large products, grouting can be carried out under certain pressure. There are two kinds of common way: one is to improve the grouting height; two is the use of the slurry can be injected into a mold of compressed air.

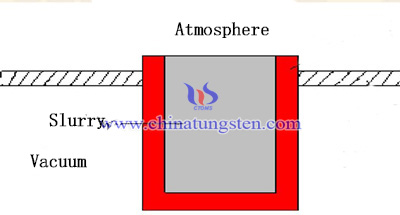

Vacuum Casting

Generally, tungsten carbide slurry will contain a small amount of air, the air will reduce the mechanical properties of cemented carbide injection parts blank density and final products. In order to meet the higher quality requirements of products, we need to make slurry vacuum treatment to exhaust air, or will be placed in the vacuum grouting process, which is called vacuum grouting. This method can accelerate the compaction of the body, improve the density and strength of the body, and reduce the defects.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com