Tungsten Trioxide Doped TiO2 Photocatalysts for Degradation of Diethyl Phthalate

- Details

- Category: Tungsten Information

- Published on Tuesday, 21 September 2021 00:52

Diethyl phthalate (DEP) is an odorless, colorless, oily liquid. It is used to make plastics, pesticides, cosmetics, and aspirin, as well as toothbrushes, auto parts, toys, tools and food packaging. At the same time, DEP has a negative impact on human health and causes environmental problems.

WO3-TiO2 Photocatalysts with Enhanced Photocatalytic Properties

- Details

- Category: Tungsten Information

- Published on Tuesday, 21 September 2021 00:23

In the past decade, the application of semiconductor powder as a photocatalytic degradation of organic pollutants in water has received widespread attention. Titanium dioxide (TiO2) suppresses amazing photocatalytic properties, including high activity, chemical stability, and low cost. However, the photocatalytic activity of TiO2 (with a band gap of 3.2 eV, excited by photons with a wavelength of less than 387 nm) is still limited by UV wavelength irradiation, so the photocatalytic process cannot effectively occur during sunlight irradiation. 4% of the total solar spectrum radiation is in the ultraviolet region.

Pt/WO3 Films for NO2 Gas Sensing

- Details

- Category: Tungsten Information

- Published on Monday, 20 September 2021 00:23

Combustion equipment and automobiles are the major sources of NOx gas including nitrogen dioxide (NO2). These gases have negative effects on the human health and can also cause acid rain. Therefore, effective adsorption materials should be used to sense and detect these gases in the atmosphere.

WO3 Nanoparticles for Photocatalytic Degradation of Dyes

- Details

- Category: Tungsten Information

- Published on Sunday, 19 September 2021 23:49

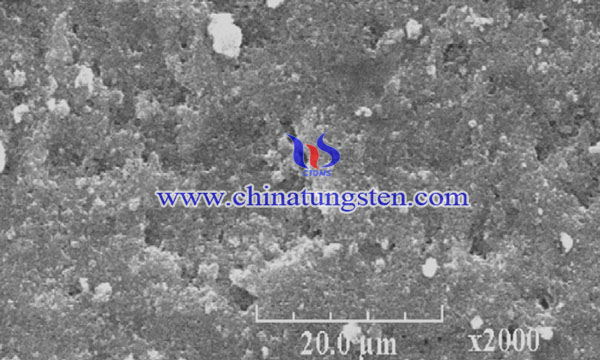

Oxide nanomaterials are used to develop advanced photovoltaic materials, photocatalysts, and smart devices. Among metal oxides, tungsten oxide (WO3) is an n-type semiconductor with a small bandgap of 2.6 eV and unique thermal, optical, physical, chemical, and electrical properties. These properties have led to many applications in chemical and selective catalysis, sensors, fuel cells, color change, and pollutant adsorption. WO3 is considered a suitable candidate for the photodegradation of organic pollutants in the visible light region.

Synthesis of Tungsten Trioxide Nanowires and Doping with Metals

- Details

- Category: Tungsten Information

- Published on Saturday, 18 September 2021 21:33

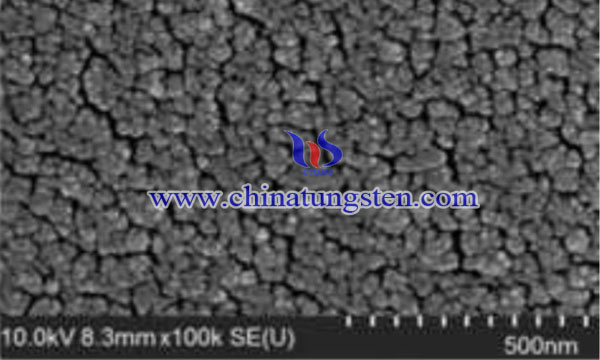

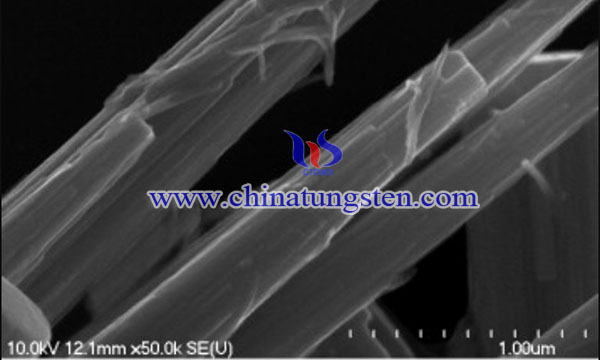

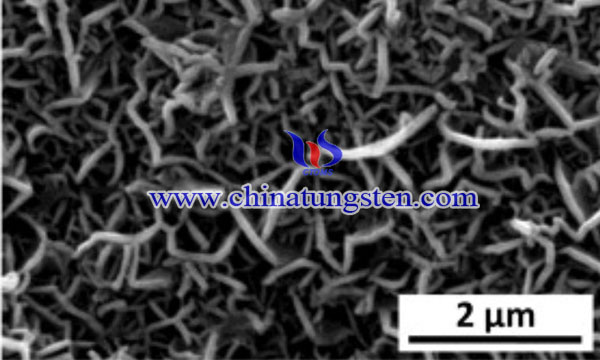

Tungsten trioxide (WO3) is an n-type semiconductor oxide that possesses a large bandgap in the range of 2.6–3.0 eV and has the potential for a variety of applications such as electrochemical devices, photovoltaic devices, photocatalytic devices, electrochromic devices, dye-sensitized solar cells, optical devices, field-emission displays, and gas sensors. Meanwhile, with the development of one-dimensional nanostructures, dimensionality and size of the materials have also been regarded as critical factors that may bring some novel and unexpected properties.

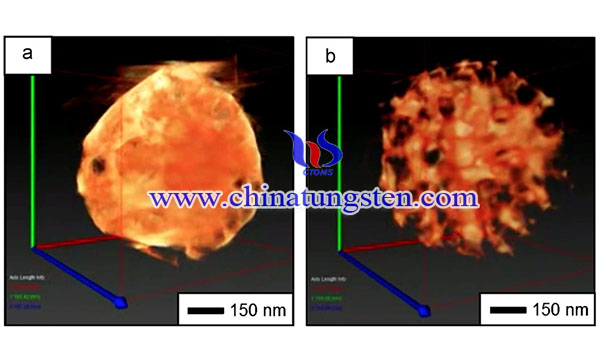

Synthesis of Spherical Macroporous WO3 Particles

- Details

- Category: Tungsten Information

- Published on Friday, 17 September 2021 01:00

Tungsten trioxide (WO3) has been extensively studied due to its affinity for visible light, chemical inertness, thermal stability, and harmlessness. These excellent properties make this material useful for solar-related applications such as photocatalysts, solar cells, water splitting, and hydrogen generation.

Au-Modified Tungsten Trioxide and Its Gas Sensing to NOx

- Details

- Category: Tungsten Information

- Published on Friday, 17 September 2021 00:36

Semiconductor metal oxides (SMOs) are highly potent gas sensors for gaseous detection in terms of screening of air eminence, low expenditure on synthesis and sensing property that can be modified. The semiconductor metal oxide gas sensor is considered the most capable gas-sensing device due to its high sensitivity, fast response, low cost, and small size.

Growth of Tungsten Trioxide on Carbon Nanowalls

- Details

- Category: Tungsten Information

- Published on Friday, 17 September 2021 00:05

WO3–Pt/C Electrocatalysts for Oxygen Reduction Reaction

- Details

- Category: Tungsten Information

- Published on Monday, 13 September 2021 14:21

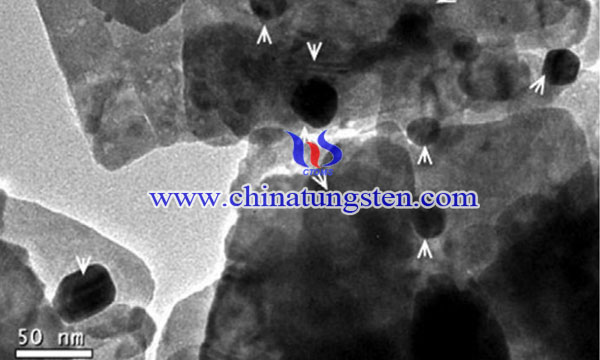

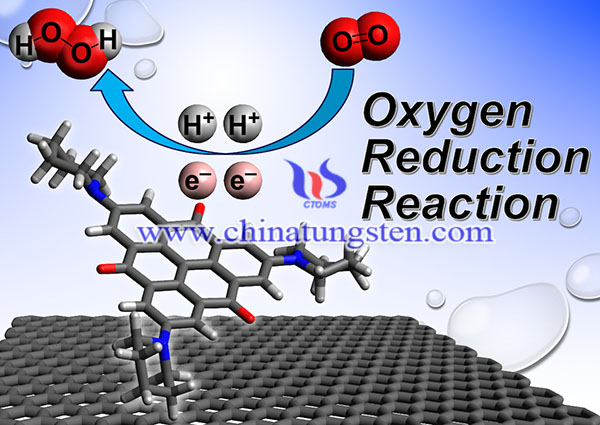

Oxygen reduction reaction (ORR) has been widely studied for its applications in fuel cells. There is a growing demand for clean energy technologies such as fuel cells. Since the energy efficiency and battery voltage of electrochemical cells are limited by the slow kinetics of ORR.Currently, platinum dispersed on carbon (Pt/C) is the most active catalyst for ORR; however, in addition to its high cost, this metal also has problems with ORR overpotential and poor methanol tolerance. Supporting by transition metal oxides such as tungsten trioxide (WO3) and titanium dioxide (TiO2) to the Pt/C electrocatalyst provide not only active sites but also electronic and ionic conductivity.

Tungsten Carbide Hollow Microsphere Prepared via Ammonium Metatungstate as Electrocatalyst Support

- Details

- Category: Tungsten Information

- Published on Monday, 13 September 2021 11:55

Hydrogen (H2) is widely concerned as the most potential candidate due to its high energy density and environmentally friendly reaction process. Electrochemical water splitting is a promising hydrogen production technology because it does not contain greenhouse gases and is economical and efficient. As a key semi-reaction process, the hydrogen evolution reaction (HER) plays a decisive role in the efficiency and cost of hydrogen production through electrochemical water splitting.

sales@chinatungsten.com

sales@chinatungsten.com