Tungsten Trioxide & Environmental Protection

- Details

- Category: Tungsten Information

- Published on Thursday, 14 October 2021 15:45

With the continuous progress of science and technology, people's quality of life has been greatly improved, but must the development of science and technology bring a good side to mankind? Not necessarily, but also has negative effects. For example, people pay more attention to pollution, which is the “sequela” left by the treatment technology failing to keep up with the development of science and technology. In order to reduce the pollution level, relevant researchers are committed to finding an efficient and environmental protection material, and Tungsten Trioxide (WO3) can be used as this material.

Production Technology of High Density Tungsten Alloy

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 October 2021 22:31

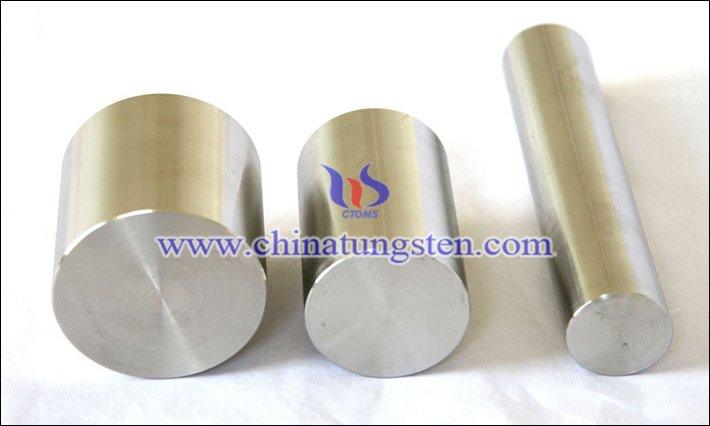

Strict control of high density tungsten alloy production technology has a vital impact on the strength, brittleness, impact toughness, hardness and corrosion resistance of products. There is an efficient and stable high density tungsten alloy production technology comprises the following steps:

Classifications of Tungsten Heavy Alloys

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 October 2021 22:24

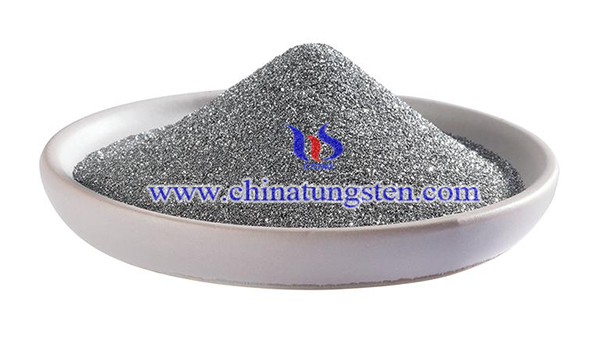

Tungsten heavy Alloy with High Specific Gravity is an alloy with tungsten as the main content and other elements added, which can form various classifications according to the added elements.

Uses of Tungsten Alloy Medical Shield

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 October 2021 22:15

Medical Tungsten Alloy Shield is an ideal choice for manufacturing medical radiation shields. With the improvement of people's living levels and the continuous development of science and technology, the concept of green and healthy life has been deeply rooted in people's hearts. Traditional radiation shielding materials have been difficult to meet people's growing needs for life and health. It is very important to find a safe and reliable protective material for people's life and health. Medical tungsten alloy shield has the characteristics of high density, strong radiation shielding and environmental protection, which just meet the needs of people pursuing healthy life, so it is widely used in many aspects of medical domain.

CS/WO3/FTO Material as Photoelectrochemical Sensors for Cobalt(II) Ions in Water

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 October 2021 18:43

Cobalt (Co) is vital to the human body and plays an important role in various biological processes. However, excessive intake of Co compounds has been shown to adversely affect the health of the skin, lungs, and thyroid. Therefore, it is necessary to design a fast, accurate and cost-effective sensor to detect the Co content in drinking water.

WO3-W2C Composite as Supercapacitor Electrodes

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 October 2021 11:46

Tungsten trioxide (WO3) has been widely applied ain polymorphism, electrochromism and gas phase change. WO3 is also a promising material that can be used for field emission, solar energy and storage.Transition metal oxides (TMO) are used in supercapacitors to increase capacitance and energy density through pseudocapacitance or Faraday mechanism. WO3 is also an excellent transition metal oxide. Although WO3 is a promising material for supercapacitor electrodes. It lacks chemical stability, yielding low life cycle values.

Tungsten Trioxide Nanoparticles for Ammonia Sensing at Room Temperature

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 October 2021 22:41

Ammonia (NH3) is a gas present in the entire atmosphere in relatively small concentrations (1–5 ppb) and is mainly emitted by human activities. Ammonia causes negative effects to living beings. Therefore, it has been suggested 25 ppm as an allowed exposure level of ammonia concentration. Thus, it is important to find a sensing material for ammonia sensing at room temperature.

Tungsten Trioxide Smart Glass

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 October 2021 16:15

Tungsten Trioxide (WO3) is a kind of relatively stable tungsten oxide. Because of its electrochromic, photochromic, gas-chromic and other special properties, WO3 smart glass is a product that meets the needs of modernization. How to apply Tungsten Trioxide to smart glass?

Tungsten Cemented Carbide Cutting Blade

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 October 2021 16:06

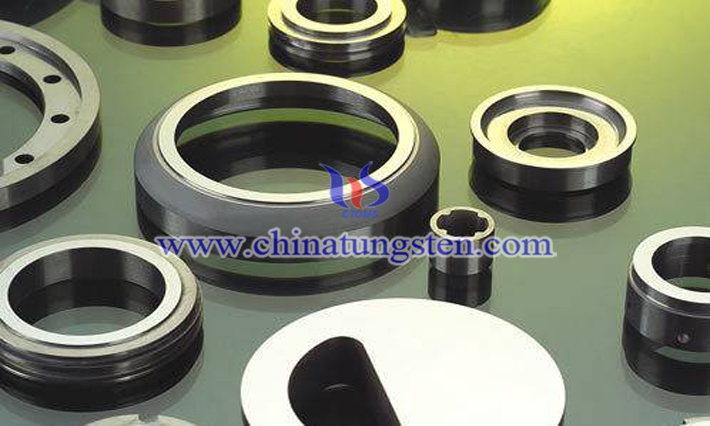

As industrial teeth, tungsten is an important raw material in machining and manufacturing. Tungsten-based cemented carbide tools have a series of excellent properties, such as high strength, good toughness, high temperature resistance, wear resistance and corrosion resistance. Even at 500 degrees Celsius or even 1000 degrees Celsius, the hardness basically keeps a high level. Tungsten Cemented Carbide Cutting Blade, which promotes the rapid development of high-speed and high-efficiency cutting technology.

Tungsten Alloy Extrusion Die

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 October 2021 15:42

Tungsten Alloy Extrusion Die is a technology for forming parts by extrusion die in the process of high-strength extrusion.

sales@chinatungsten.com

sales@chinatungsten.com