Classifications of Tungsten Heavy Alloys

- Details

- Category: Tungsten Information

- Published on Wednesday, 13 October 2021 22:24

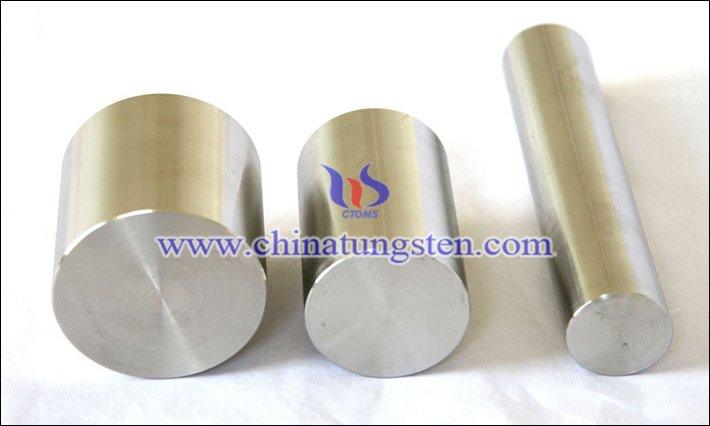

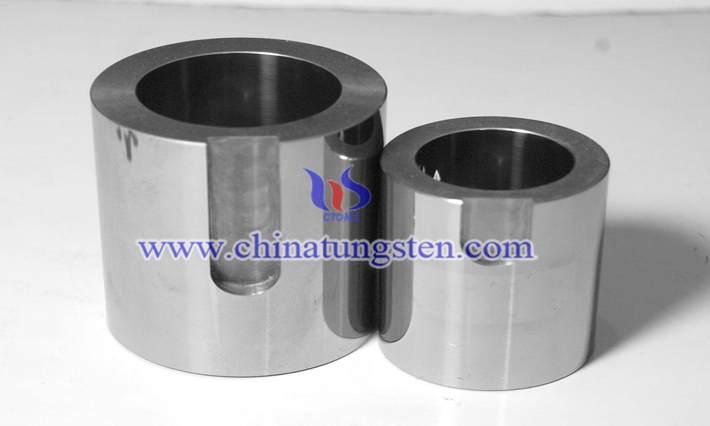

Tungsten heavy Alloy with High Specific Gravity is an alloy with tungsten as the main content and other elements added, which can form various classifications according to the added elements.

1.W-Ni-Cu Alloy

W-Ni-Cu alloy is mainly made by mixing, pressing and sintering W, Ni and Cu powders. Among them, W content is generally 80%~90%, and Ni and Cu binders are added to form a two-phase alloy after liquid phase sintering, and the density is close to the theoretical density. In this alloy, except W and Ni, the remaining content is mainly copper, which can improve the strength, plasticity and conductivity of tungsten alloy. In terms of properties, the alloy has no magnetism for special application, and other physical properties are the same as the overall properties of tungsten alloy.

2.W-Ni-Fe Alloy

W-Ni-Fe alloy is made by mixing, pressing and sintering W, Ni and Fe powders. Among them, tungsten accounts for 80%~90%, while nickel and iron play the role of binder. Two-phase alloy is formed after liquid phase sintering, and its density is close to theoretical density. Nickel is an essential element in liquid phase sintering process, and its content is generally 0.5%~12%. If it is more than 12%, the heat resistance and corrosion resistance of the alloy will decrease. Iron can improve strength and plasticity in this alloy. This alloy has certain magnetism, and can be used as the core material of armor-piercing projectile, high momentum killing debris such as sub munitions, counterweight and other industrial fields. Compared with W-Ni-Cu alloy, this alloy has better strength and plasticity.

3.W-Ni-Cr Alloy

Cr element in W-Ni-Cr alloy is used as solution reinforce additive element in this alloy, which can improve corrosion resistance and high temperature oxidation resistance, and can also improve the high temperature strength and hardness of the alloy. The general content is 0.2%~5%. The hardness of this alloy is high (HV=600, while the hardness of W-Ni- Fe alloy is HV=310). The mechanical properties of the alloy depend on the ratio of Cr/Ni. When the ratio is small, the plasticity is better and the hardness is slightly higher. When the ratio is large, the hardness is high, the tensile strength is low, and there is almost no plasticity.

4.W-Ni-Mo Alloy

Mo element in this alloy has the same effect as Cr element in W-Ni-Cr alloy, which is used as solution reinforce additive element, and its content is 0~25%. It can be dissolved in the bonding phase during liquid phase sintering, which plays the role of solid solution strengthening and grain refinement, and effectively improves the mechanical properties, high temperature strength and thermal shock resistance of the alloy. The results show that with the increase of Mo content, the yield strength, ultimate tensile strength and hardness of the alloy will increase, while the ductility and sintering density will decrease.

5.W-Ni-Co Alloy

As a synergistic reinforce additive element, Co can improve the high-temperature properties of the alloy, especially strengthen the bonding phase, avoid the formation of inter-alloy compounds, and obviously improve the high-temperature strength and hardness of the alloy, with a general content of 0.5%~5%. The results show that when the temperature is higher than 500 degrees centigrade, the strength and plasticity of this alloy are obviously higher than those of W-Ni-Fe alloy.

- Tungsten Alloy Manufacturer & Supplier, Chinatungsten Online: www.tungsten-alloy.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com