Tungsten Split Shot Fishing Sinkers 2

- Details

- Category: Tungsten Information

- Published on Tuesday, 02 September 2014 08:47

Round-shaped tungsten split shot fishing sinkers

Round-shaped tungsten split shot fishing sinkers, compared with other split shot fishing sinkers, features for its capacity of freeing from snags and rocks easier.

Bull tungsten shot split shot fishing sinkers

Bull shot tungsten split shot fishing sinkers are a unique bullet shaped and variations of split shots. It maintains a groove for holding line and is an oval shape, making it more snag resistant.

The function of making it easier to add a little weedless weight to the line is where bull shot tungsten split shot fishing sinkers shines. Bull shot is great for finesse fishing.

Traditionally, lead is the general material for making split tungsten shot fishing sinkers, while now as the government and people are more cared about the environment protection, more and more anglers adopt tungsten alloy, a greener and safer choice for the environment, to be the materials for their split shot fishing sinkers.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Application Tungsten Alloy in Ordnance Components

- Details

- Category: Tungsten Information

- Published on Monday, 01 September 2014 18:14

In World War II, projectiles made from tungsten alloys helped Allied forces achieve victory. Today, Mi-Tech Metals’ high-density tungsten alloys are still proving their worth in ordnance applications around the world. The compact yet uncompromising strength found in tungsten alloys allows us to offer the highest quality in hyper-velocity, armor-penetrating applications, fragmentation devices and kinetic energy penetrators. Flexible manufacturing techniques and additives also allow us to vary properties such as elongation, ultimate tensile strength, and hardness to ensure the best possible material for your unique needs.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Application Tungsten Alloy in Ordnance Components

- Details

- Category: Tungsten Information

- Published on Monday, 01 September 2014 18:09

In World War II, projectiles made from tungsten alloys helped Allied forces achieve victory. Today, Mi-Tech Metals’ high-density tungsten alloys are still proving their worth in ordnance applications around the world. The compact yet uncompromising strength found in tungsten alloys allows us to offer the highest quality in hyper-velocity, armor-penetrating applications, fragmentation devices and kinetic energy penetrators. Flexible manufacturing techniques and additives also allow us to vary properties such as elongation, ultimate tensile strength, and hardness to ensure the best possible material for your unique needs.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Applications of Tungsten Alloys Radiation Shielding

- Details

- Category: Tungsten Information

- Published on Monday, 01 September 2014 17:48

Whether you need to protect sensitive electronic equipment or delicate human tissue, the energy-absorbing properties of Mi-Tech Metals’ tungsten alloys make them exceptional choices for radiation shielding applications, in both medical and industrial settings.

Tungsten alloys are used for radioactive source containers, gamma radiography, shields, and source holders for oil-well, logging, and industrial instrumentation. High-density alloys also serve as collimators and radiation shielding in cancer therapy, as well as syringe protection for radioactive injections. When you need to direct a specific amount of radiation to a targeted area, tungsten alloys provide the control you need. Mi-Tech Metals’ high-density alloys will continue to perform, even under extreme, high-heat conditions.

Compared to traditional radiation shielding materials, tungsten alloys provide excellent value. A high-density alloy can provide the same energy absorption as lead using 1/3 less material! Unlike lead, you’ll also reduce administration costs by eliminating the need to obtain special licensing—it’s not required.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Split Shot Fishing Sinkers 1

- Details

- Category: Tungsten Information

- Published on Monday, 01 September 2014 11:45

Tungsten split shot fishing sinkers feature for a groove that runs the full length of the sinker are one of the most well-known and widely used sinkers. The groove holds the line once the sinker is impacted in place.Split shot fishing sinkers are often used with live-bait offerings. The combination of a split shot above a hook with a worm suspended below a bobber is appreciated by many experienced anglers because this perfect combination has caught thousands of fishes for them.

According to the shape of the tungsten split shot fishing sinkers, we can classify into the three types.

Removable tungsten split shot fishing sinkers

Removable tungsten split shot fishing sinkers feature for small handles on the opposite side of the opening, allowing you to squeeze the shot back off your line and allowing them to be removed and reused on your lines over and over again, which prolong the life.

Removable tungsten split shot fishing sinkers are made by a patented process which forms very soft lead into precise pieces, resulting in a controlled hinge that can be squeezed onto the line on by fingers, it means that you can interchange sinkers instantly with just a snap of your fingers, no tools or teeth are needed.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

What is Tungsten and How Tungsten Used?

- Details

- Category: Tungsten Information

- Published on Monday, 01 September 2014 11:08

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Introduction and Application of Ferro Tungsten

- Details

- Category: Tungsten Information

- Published on Friday, 29 August 2014 09:37

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

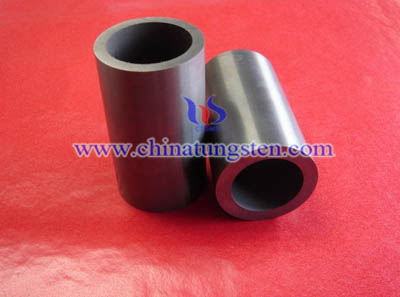

Introduction of Tungsten Pipe

- Details

- Category: Tungsten Information

- Published on Friday, 29 August 2014 09:21

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Introduction of Tungsten Tube

- Details

- Category: Tungsten Information

- Published on Friday, 29 August 2014 09:06

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Fishing Sinkers 2

- Details

- Category: Tungsten Information

- Published on Friday, 29 August 2014 08:46

However, the impact of lead fishing tackle has not been as well studied, but the poisoning is greatly touch everyone, because it’s everyone’s oblige to protect the environment from poisoned. So, more and more people call to adopt non-toxic materials like tungsten to be the materials for the tungsten fishing sinkers. As a result, tungsten with the environment friendly and easily machined properties praise highly between the fishing sinkers area.

There are many different types of tungsten fishing sinkers and a variety of shapes and sizes that run from the basic to the bizarre. Split shot fishing sinkers, rubber core fishing sinkers, bell fishing sinkers, pyramid fishing sinkers, bank fishing sinkers, walking fishing sinkers, bullet fishing sinkers, egg fishing sinkers, dollar fishing sinkers, ball fishing sinkers, banana fishing sinkers and one or two eye fishing sinkers. And the pyramid fishing sinkers, bank fishing sinkers, dollar fishing sinkers, ball fishing sinkers, banana fishing sinkers and one or two eye sinkers are the most commonly used sinkers for saltwater fishing.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com