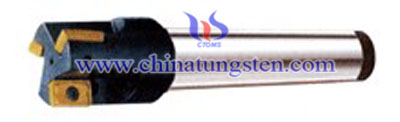

Tungsten Carbide Milling Cutter Milling Introduction

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 November 2014 17:28

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Indexable Cutting Tool’s Productivity Advantages

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 November 2014 16:52

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Indexable End Mill’s Cost Advantage

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 November 2014 16:50

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

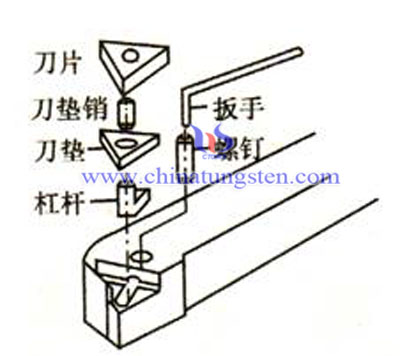

Tungsten Carbide Indexable Turning Tool Lever-type Clamping Introduction

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 November 2014 16:48

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Indexable Turning Tool Eccentric Clamping Introduction

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 November 2014 16:46

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

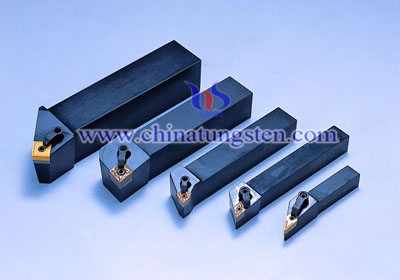

Tungsten Carbide Indexable Turning Tool Introduction

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 November 2014 16:44

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Dropshot Weights-2

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 November 2014 08:59

Tungsten dropshot weights create twice the sound of lead as it contacts structure, and they sink quickly with the properties of high mass and low volume. They are environmentally safe, because of the material tungsten is non-toxic, which is more important for us.

Tungsten dropshotweights are available in a teardrop model and a thin model.

Tungsten dropshot weights of Chinatungsten Online feature a high quality clip designed to hold fishing line without tying a knot, yet allows line to slip out when the weight becomes snagged allowing the rest of the rig to remain intact.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Tungsten Dropshot Weights-1

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 November 2014 08:55

Tungsten dropshot weights have really turned into an effective and widespread way of rigging a worm and catching fish.

Tungsten dropshot weights feature a high quality clip designed to hold the line without tying a knot and slipping off the rig when they get hung up without breaking off the hook. Then, all you have to do is clip on another weight and your back to fishing without re-tying the whole rig.

Because tungsten is denser than lead, so tungsten dropshot weights offers a smaller more compact design as compared to its lead counter part at the same physical weight, about 25% smaller than conventional lead weights.

Tungsten dropshot weights are extremely dense providing anglers the sensitivity they need when fishing soft plastics. They can transmit the feel of the bottom structure extremely well, allowing you to have more sensitivity by detecting subtle bottom changes that with lead would go unnoticed.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

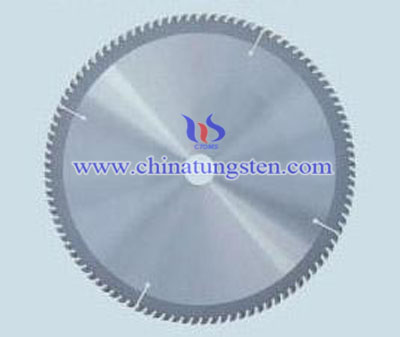

Tungsten Carbide Saw Blade’s Common Specifications

- Details

- Category: Tungsten Information

- Published on Friday, 07 November 2014 16:53

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How to Identify High-quality Tungsten Carbide Saw Blade

- Details

- Category: Tungsten Information

- Published on Friday, 07 November 2014 16:51

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com