Tungsten Carbide Indexable End Mill’s Cost Advantage

- Details

- Category: Tungsten Information

- Published on Tuesday, 11 November 2014 16:50

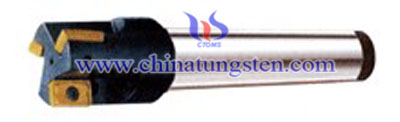

Tungsten carbide indexable end mill is suitable for milling shallow grooves, step surface, and boring blind holes. Tungsten carbide indexable end mill has many advantages in cost saving:

Firstly, it can reduce the cutting tool replacement cost. Cobalt high speed steel and solid tungsten carbide are relatively more expensive. When they break, the whole cutting tool should be replaced with a new one. Instead, in tungsten carbide indexable end mill, an indexable insert is worth just a few dollars.

In addition, tungsten carbide indexable end mill do not need to be reground, which is a labor-intensive and costly work. Also, regrinding may cause damages in cutting tool diameter size. During slotting machining, that would mean extra cost of a finish machining to meet the size requirements.

What is more, tungsten carbide indexable end mill has wide universality which helps reduce the cost. In many cases, it can be used in different kinds of workpiece materials and machining just by replacing the blade materials and groove shapes in the same cutter body.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com