Unlocking the Secrets of Tungsten Oxide Film: Preparation Process and Performance Regulation

- Details

- Category: Tungsten Information

- Published on Monday, 24 March 2025 14:46

In the quest to explore novel dimming devices, tungsten oxide (WO3-x) thin films have emerged as a rising star, radiating a unique allure. With their exceptional thermochemical stability, semiconductor properties, and remarkable abilities such as photochromism, electrochromism, and acousto-optic effects, they are steadily gaining prominence in the field of materials science. WO3-x thin films are becoming the "darling" of next-generation dimming devices, poised to replace titanium dioxide (TiO2) thin films and lead a new trend in dimming materials.

What Are the Semiconductor Properties of Tungsten Disulfide?

- Details

- Category: Tungsten Information

- Published on Friday, 21 March 2025 17:00

Tungsten disulfide (WS₂) produced by CTIA GROUP LTD, as a transition metal dichalcogenide, has garnered significant attention in materials science due to its semiconductor properties. For instance, in the field of optical communication, light-emitting diodes based on single-layer WS₂ hold the potential to achieve high-speed, low-power optical signal emission, thereby improving data transmission rates and efficiency. The following sections elaborate on the semiconductor properties of WS₂ from the perspectives of band structure, carrier mobility, and optical characteristics.

What Are the Thermoelectric Properties of Tungsten Disulfide?

- Details

- Category: Tungsten Information

- Published on Friday, 21 March 2025 16:55

Tungsten disulfide (WS₂) produced by CTIA GROUP LTD is a typical tungsten compound. In addition to its excellent catalytic, lubricating, and optical properties, it also exhibits outstanding thermoelectric performance, making it highly regarded in the field of energy conversion and utilization.

How to Modify Tungsten Disulfide with Polymer?

- Details

- Category: Tungsten Information

- Published on Wednesday, 19 March 2025 17:56

Tungsten disulfide (WS₂) from CTIA GROUP LTD is a layered transition metal sulfide composed of tungsten and sulfur atoms bonded through covalent bonds. It exhibits excellent lubricity and semiconductor properties, making it widely applicable in fields such as lubrication, catalysis, and electronics. However, to further enhance the overall performance of WS₂, researchers often use polymers to modify it.

Effect of Preparation Parameters on Tungsten Disulfide Performance

- Details

- Category: Tungsten Information

- Published on Wednesday, 19 March 2025 17:50

Common preparation methods for tungsten disulfide (WS₂) from CTIA GROUP LTD include chemical vapor deposition (CVD), mechanical ball milling, hydrothermal synthesis, and sol-gel methods. These processes involve various preparation parameters such as reaction temperature, reaction time, reactant concentration, reaction atmosphere, and catalysts. So, how do these preparation parameters affect the properties of WS₂ from CTIA GROUP LTD?

What Impurity Elements Are There in Tungsten Disulfide?

- Details

- Category: Tungsten Information

- Published on Wednesday, 19 March 2025 17:47

The chemical composition of tungsten disulfide (WS₂) from CTIA GROUP LTD primarily consists of tungsten (W) and sulfur (S). However, during actual production processes, WS₂ often contains trace amounts of other elements, such as oxygen, carbon, and others. These impurity elements can influence the properties of WS₂ in various ways.

What Are the Effects of Non-Metallic Doping on Tungsten Disulfide Performance?

- Details

- Category: Tungsten Information

- Published on Wednesday, 19 March 2025 17:40

Non-metal doping of tungsten disulfide (WS₂) involves introducing non-metal atoms into the WS₂ crystal lattice to modify its physical and chemical properties. What are the effects of non-metallic doping on tungsten disulfide performance?

Why Is Tungsten Disulfide Compounded with Graphene?

- Details

- Category: Tungsten Information

- Published on Wednesday, 19 March 2025 17:33

The composite of tungsten disulfide (WS₂) and graphene is a significant research direction in materials science. By combining the strengths of both materials, a synergistic effect is achieved, endowing the composite with exceptional properties such as enhanced catalytic and electrochemical performance.

Why Is Tungsten Disulfide Compounded with Carbon Nanotubes?

- Details

- Category: Tungsten Information

- Published on Wednesday, 19 March 2025 17:25

The combination of tungsten disulfide (WS₂) and carbon nanotubes (CNTs) primarily aims to leverage the strengths of both materials, achieving complementary and synergistic enhancements in performance to meet the demands of various applications. For instance, in reactions such as hydrogenation and hydrogen evolution, WS₂-CNT composites exhibit superior catalytic performance compared to their inpidual components, showing great potential for widespread use in energy conversion and chemical industries. Additionally, due to their excellent electrical properties and high specific surface area, WS₂-CNT composites can be utilized to fabricate high-performance gas sensors, biosensors, and more.

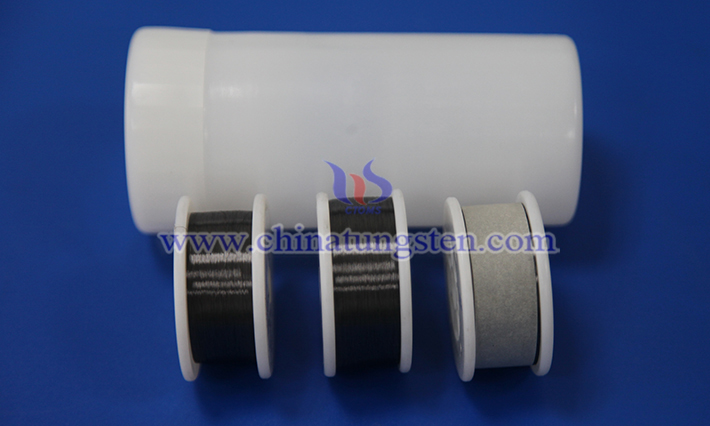

Packaging for High-Cut Resistance Tungsten Wire

- Details

- Category: Tungsten Information

- Published on Monday, 17 March 2025 19:09

The packaging of high-cut resistance tungsten wire (i.e., tungsten wire with high resistance to cutting) is typically designed based on its application, transportation requirements, and material properties to ensure safety and integrity. Tungsten wire itself is a high-hardness, high-melting-point metal material widely used in industrial cutting, electronic devices, and high-temperature environments. Therefore, its packaging must not only protect the wire from external damage but also facilitate storage and usage.

sales@chinatungsten.com

sales@chinatungsten.com