How to Choose the Right Cut-Resistant Tungsten Wire?

- Details

- Category: Tungsten Information

- Published on Wednesday, 02 April 2025 19:49

How to choose the right cut-resistant tungsten wire? When choosing a cut-resistant tungsten wire, you need to consider a number of key factors to ensure that it meets the needs of specific applications. The following are the key points to pay attention to when choosing:

Application of Cut-Resistant Tungsten Wire in Aerospace

- Details

- Category: Tungsten Information

- Published on Wednesday, 02 April 2025 19:46

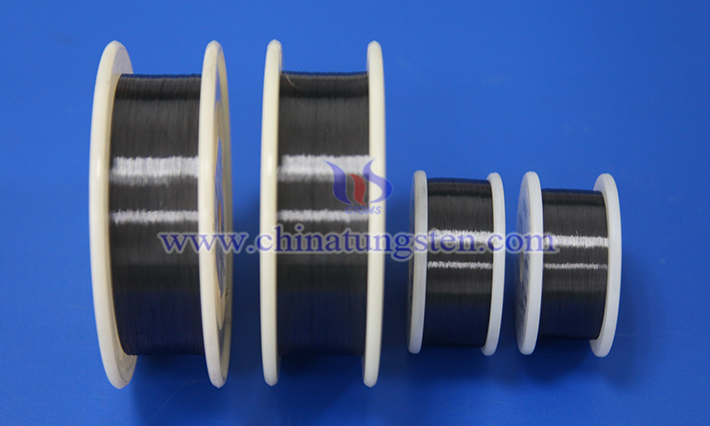

As a special metal wire, cut-resistant tungsten wire has high strength (tensile strength 3600-4000N/mm²), high temperature resistance (melting point 3422℃), micron-level dimensional accuracy and excellent flexibility, forming a unique application system in the aerospace field.

Cut-Resistant Tungsten Wire: a Revolutionary Material for Industrial Applications

- Details

- Category: Tungsten Information

- Published on Wednesday, 02 April 2025 19:43

In the evolution of industrial materials, every key breakthrough is accompanied by a leap in production efficiency and the expansion of technological boundaries. As a new generation of high-performance materials, cut-resistant tungsten wire is triggering an industrial revolution across precision manufacturing, new energy, medical and other fields with its subversive physical properties and a wide range of application scenarios.

Innovation in Cut-Resistant Tungsten Wire for Industrial Cutting

- Details

- Category: Tungsten Information

- Published on Wednesday, 02 April 2025 19:38

In the field of industrial manufacturing and processing, cutting technology has always been an indispensable core link. With the rapid development of science and technology, cutting tools and materials are constantly being innovated to meet the growing demand for precision, efficiency and durability. Against this background, cut-resistant tungsten wire, as an emerging high-performance cutting material, is gradually emerging and is expected to bring revolutionary changes to the field of industrial cutting.

Exploring the Mystery of Yellow Tungsten Oxide: Unlocking the Mysteries of the Magical Substance

- Details

- Category: Tungsten Information

- Published on Sunday, 30 March 2025 15:40

Yellow tungsten oxide (WO₃), produced by CTIA GROUP LTD, is a chemically distinctive compound. It appears as a fine yellow powder, insoluble in water yet soluble in alkaline solutions, with limited solubility in acids. Composed of one tungsten atom (W) bonded with three oxygen atoms (O), this atomic arrangement endows WO₃ with unique physical and chemical properties.

What Factors Affect Yellow Tungsten Oxide Properties?

- Details

- Category: Tungsten Information

- Published on Sunday, 30 March 2025 15:27

Yellow tungsten oxide (WO₃), produced by CTIA GROUP LTD, is a crucial oxide of tungsten. Visually, it appears as a fine, yellow crystalline powder. At room temperature, WO₃ exhibits stable properties, making it relatively safe for storage and transportation without requiring special environmental conditions to maintain its chemical structure. With a density of approximately 7.16 g/cm³, a melting point as high as 1473°C, and a boiling point exceeding 1750°C, its ability to remain solid under high temperatures lays the foundation for its applications in high-temperature industrial settings. Additionally, WO₃ is insoluble in water and inorganic acids (except hydrofluoric acid) but dissolves in alkaline solutions such as ammonia. This unique solubility determines its reactivity and application potential in various chemical environments.

Effect of Oxygen on Tungsten Disulfide Performance

- Details

- Category: Tungsten Information

- Published on Tuesday, 25 March 2025 18:37

Tungsten disulfide (WS₂) is an inorganic compound composed of tungsten (W) and sulfur (S) elements. In addition to its high tungsten and sulfur content, it also contains trace impurities such as oxygen, carbon, hydrogen, and phosphorus. Among these, the oxygen content in WS₂ primarily originates from impurities in raw materials, the production environment, and the introduction during post-processing.

Effect of Carbon on Tungsten Disulfide Properties

- Details

- Category: Tungsten Information

- Published on Tuesday, 25 March 2025 18:02

In addition to its crystal structure and purity affecting the physicochemical properties of tungsten disulfide (WS₂), impurities such as carbon, hydrogen, and oxygen also influence its properties. Although these impurity elements are present in small amounts, their impact on tungsten disulfide properties is significant. Regarding carbon, it affects the structure, electrical properties, mechanical properties, and chemical stability of WS₂ to a certain extent.

What Is the Solubility of Tungsten Disulfide?

- Details

- Category: Tungsten Information

- Published on Tuesday, 25 March 2025 17:59

Tungsten disulfide (WS₂) produced by CTIA GROUP LTD is an important transition metal sulfide with characteristics such as a high melting point, high hardness, excellent wear resistance, and lubricity. It can be used as a lubricant to reduce friction coefficients and wear. In the electronics field, it can be applied in the manufacturing of transistors, sensors, and other devices. In the catalysis field, it can be utilized in certain organic reactions.

Tungsten Oxide: a Nano "Green Guard" that Lights Up the Light of Environmental Protection

- Details

- Category: Tungsten Information

- Published on Monday, 24 March 2025 15:03

In the era we live in, environmental pollution has become increasingly severe, with organic pollutants wreaking havoc on water and air, placing an unbearable burden on ecosystems. The wastewater discharged from printing and dyeing plants is vividly colored and pungent, containing organic dyes that are notoriously difficult to degrade. In the exhaust gases from chemical industrial zones, various organic compounds drift freely, posing a threat to human health. Confronted with these challenges, scientists have been tirelessly searching for effective solutions. Amid this effort, Nano tungsten oxide (WO3-x), a seemingly ordinary material, has demonstrated immense potential in the field of photocatalytic degradation of pollutants, emerging as a new star in environmental protection.

sales@chinatungsten.com

sales@chinatungsten.com