Photocatalytic Activity of Silica/Bismuth Tungstate on Methylene Blue

- Details

- Category: Tungsten Information

- Published on Friday, 08 February 2019 23:29

Among many photocatalytic materials, bismuth tungstate is a kind of visible-light photocatalyst with good photocatalytic activity. Bi2WO6 is a typical semiconductor material. Electrons are stimulated by light and leave corresponding holes to form electron-hole pairs. These photogenerated electron-hole pairs have strong redox ability. They are easy to react with organic substances and polymer, and they respond well to visible light because of their narrow band gap.

Optimum Cocatalyst-Tungsten Carbide

- Details

- Category: Tungsten Information

- Published on Friday, 08 February 2019 23:14

Since the discovery of platinum-like catalytic performance by American scientists in the last century, tungsten carbide has been found to have high catalytic or catalytic activity in hydrocarbon reforming, decomposition, hydrogenation, isomerization, electrochemical oxidation of hydrogen and alcohols, and electrochemical reduction of oxygen.

Domestic Preparation of Titanium-Tungsten Powder as Denitrification Catalyst

- Details

- Category: Tungsten Information

- Published on Friday, 08 February 2019 22:51

Nitrogen oxide is a serious air pollutant, which can cause environmental problems such as acid rain and photochemistry smog. It can also cause direct harm to human respiratory system. To win the Blue Sky Defense War, the important task is to effectively control the emission of NOx.

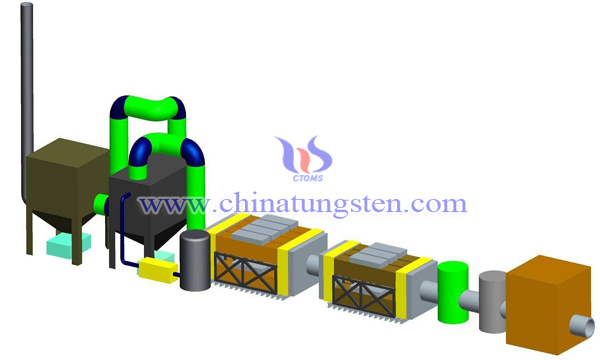

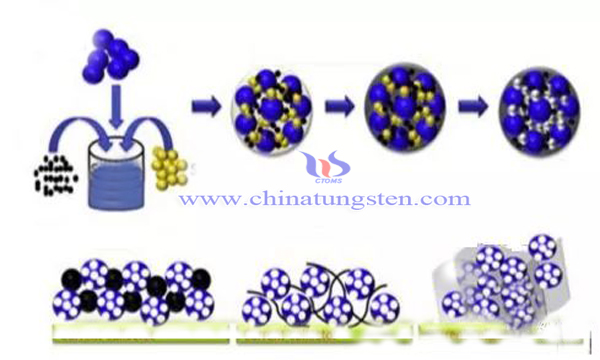

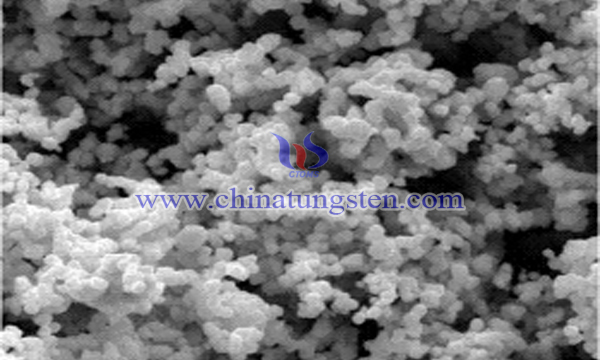

Nano Tungsten-copper Rare Earth Composite Powder Preparation Process

- Details

- Category: Tungsten Information

- Published on Thursday, 07 February 2019 22:09

Nano tungsten-copper composites have excellent properties of tungsten and copper, and are widely used in electrode materials, electrical contact materials, electronic packaging materials and heat sink materials. However, the disadvantages of immiscible tungsten and copper elements, large melting point difference, poor wettability and low density after sintering lead to the decrease of properties and the increase of production cost of tungsten-copper composites.

Cesium Tungstate Low Cost Preparation

- Details

- Category: Tungsten Information

- Published on Thursday, 07 February 2019 21:59

Cesium tungstate (Cs2WO4) is a new material discovered in recent years. At present, some famous coating companies in Japan, Germany, the United States and other countries are vigorously developing transparent heat insulation coatings of cesium tungstate.

Efficient Preparation of Nano Tungsten Trioxide by Vapor Deposition

- Details

- Category: Tungsten Information

- Published on Thursday, 07 February 2019 21:51

Tungsten trioxide (WO3) is an important n-type semiconductor oxide. It has many crystal structures. It has been extensively studied because of its unique physical and chemical properties. It has been applied in the fields of electrochromic, photochromic, sensing and catalysis.

Nano Tungsten Carbide Spray Conversion

- Details

- Category: Tungsten Information

- Published on Thursday, 07 February 2019 21:39

Ultrafine/nanocrystalline cemented carbides overcome the contradiction between strength and toughness, have high toughness and wear resistance, and have become a hotspot in the field of cemented carbide technology in the world.

Nd-doped Bismuth Tungstate Photocatalyst

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 February 2019 22:27

Bismuth tungstate is a new type of photocatalyst material, which is easily stimulated by visible light, can degrade organic pollutants. The reaction conditions are mild, the degradation is thorough, and the environment is clean. Bismuth tungstate has become one of the hot technologies in the field of pollution control.

Tungsten Carbide Electrocatalytic Hydrogen Evolution

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 February 2019 22:17

Clean energy is one of the most important problems in the sustainable development of human society. Hydrogen is not only an ideal clean energy source, but also an important chemical raw material, which has attracted worldwide attention. On the other hand, hydrogen fuel cell has become one of the hotspots of new energy vehicles in the future due to its high energy, high efficiency and environmental friendliness.

Hydrated Tungsten Oxide Nano-Electrochromic Films

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 February 2019 22:00

Electrochromic means that the material has reversible color when applied voltage. Materials that can undergo reversible changes in optical properties (e.g., color) based on electrochemical redox reactions are called electrochromic materials. Tungsten oxide has become a hotspot in electrochromic research due to its excellent electrochromic properties.

sales@chinatungsten.com

sales@chinatungsten.com