Tungsten Carbide Ball Bearing II

- Details

- Category: Tungsten Information

- Published on Friday, 18 September 2015 16:37

- Written by xiaobin

- Hits: 504

There are twomain sections of tungsten carbide ball bearing, one is ball bearings with integral shafts, the other is specifically divided into thrust bearings, linear bearings, angular contact bearings and the most common ball bearing, the radial bearing.

1. Tungsten Carbide Ball Bearings with Integral Shafts

The integral shaft or “water pump spindle bearing” was originally designed as a support bearing for use in automotive engine cooling systems. Due to its versatile design, this bearing can also be used in fans, vane pumps and washing machines. Integral shaft bearings are generally double row ball bearings (two sets of balls) comprised of an outer race with two ball tracks or raceways and an inner “race” that is machined directly into the surface of an internal shaft. They do not have an inner ring like conventional double row ball bearings. As the name suggests, an “integral shaft ball bearing” is simply tungsten carbide ball bearing with a shaft that is an integral part of the bearing, i.e., the shaft cannot be removed without disassembling or otherwise destroying the bearing.

More infomation about tungsten carbide ball bearing, click here:

http://news.chinatungsten.com/en/tungsten-information/78745-ti-10022

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Ball Bearing

- Details

- Category: Tungsten Information

- Published on Friday, 18 September 2015 16:31

- Written by xiaobin

- Hits: 384

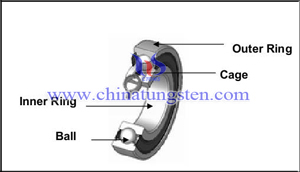

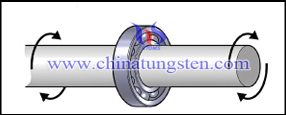

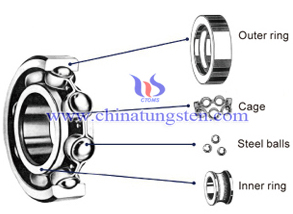

Tungsten carbide ball bearing is one of two types of rolling bearings, the other being a roller bearing. The purpose of tungsten carbide ball bearing is to reduce friction and to support radial and axial loads. There are four main parts of a ball bearing: two grooved, ring-like races or tracks (inner and outer ring), a number of hardened steel balls and a cage to space, separate and guide the balls. The inner race is the smaller of the two races and fits inside the larger outer race. The balls fill the space between the two races and allow the bearing to rotate smoothly within the grooves.

Tungsten carbide ball bearings come in all shapes, sizes and materials and are by far the most common bearing used. They are a required component in many industrial, residential and commercial applications and play an important role in everyday life. These bearings are used in a wide range of products including heavy industrial equipment, such as steel rolling mills, washing machines and personal computer hard drives. Some of their not so common uses are in military aircraft and oil drilling equipment.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Penetrator

- Details

- Category: Tungsten Information

- Published on Friday, 18 September 2015 16:20

- Written by yanna

- Hits: 330

Numerous types of penetrators exist. Tungsten is often a material of choice in the penetrator art. A typical method for fabricating penetrators from tungsten involves the use of tungsten powder metal, which is a heterogeneous mixture of tungsten and other metal powders. The mixture of powders is compacted into the desirable shape, liquid phase sintered and processed into penetrators.

Tungsten penetrator has superior, sought after properties. It may be produced by employing metal matrix composite technology. The tungsten penetrator herein differs from other penetrators in the prior art in that it is composed of tungsten whiskers. Although different crystalline orientations of tungsten whiskers may be employed within the scope of the present invention, the orientation is the one preferred.

Tungsten penetrators already in use tend to form mushroom heads upon impact of a hard target. The formation of a mushroom head decreases the penetration ability of a penetrator. Hence, the performance of a penetrator would be enhanced if the formation of a mushroom head could be eliminated.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Military Spheres Applications

- Details

- Category: Tungsten Information

- Published on Friday, 18 September 2015 16:26

- Written by yanna

- Hits: 348

With the highest density weighting in at 1.7 times heavier than lead, tungsten alloy is the best ideal material for military defense used in military. On the one hand, tungsten is non-toxic, so it is the related product for lead which was used in bullet and shot to reduce the environmental hazardous materials in the military field. On the other hand owing to its great hardness and resistance to high temperature, tungsten alloy sphere has been applied in military defense increasingly today.

Tungsten alloy sphere can be also used as bullets or pellets in many military filed, the main advantages of tungsten alloy balls which made as pellet are that it's very dense, and very hard. The density allows the pellets to fly long distances without slowing down, while the hardness allows the pellets to keep their shape while being accelerated by the powder charge, which increases the muzzle velocity.

As well tungsten alloy spheres are widely used in hand grenade, armor piercing projectile, prefabricated fragments, tungsten alloy sphere is in small volume with high density, which means it could be used in some fields need the little but heavy parts, such as counterweights for military defense, projectiles in the missile weapons, armor piercing ammunition, hunting equipment, armor piercing ammunition,tungsten alloy bullet.

钨产品生产商、供应商:中钨在线科技有限公司

产品详情查阅:http://www.chinatungsten.com

订购电话:0592-5129696 传真:0592-5129797

电子邮件:sales@chinatungsten.com

钨钼文库:http://i.chinatungsten.com

钨新闻、价格手机网站,3G版:http://3g.chinatungsten.com

钼新闻、钼价格:http://news.molybdenum.com.cn

关注微信公众号“中钨在线”,了解每日最新钨钼价格

Introduction to Tungsten Carbide Tipped Reamers Ⅱ

- Details

- Category: Tungsten Information

- Published on Thursday, 17 September 2015 17:33

- Written by zhihua

- Hits: 339

(This article is divided into two parts and this is Part Ⅱ. For Part Ⅰ please refer to http://news.chinatungsten.com/en/tungsten-information/78698-ti-10017)

------END-------

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com