Tungsten Carbide Ball Bearing VIII

- Details

- Category: Tungsten Information

- Published on Wednesday, 23 September 2015 17:15

- Written by xiaobin

- Hits: 279

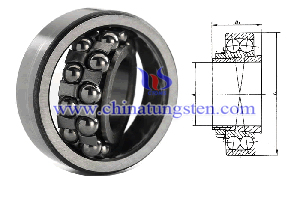

The maximum capacity or filling slot type radial ball bearings have inner and outer races that are notched so that when they are aligned, additional balls can be slipped into the slot in order to fill the bearing. The advantage of this bearing is that the entire groove is filled with balls. This is called a full complement/capacity which allows these bearing types to carry increased load ratings.

Although designed to carry primarily radial loads, which are loads perpendicular to the axis of the bearing, the deeper the contour of the rolling track, the greater the ability of the bearing to tolerate thrust loads placed along the axis of the bearing. These bearings are designed for use in high speed, high precision applications for the agriculture, automotive and chemical industries. They are also found in engines, motors, hand tools, fans, etc.

For tariff purposes, radial ball bearings are divided into three types: single row ball bearings, double row ball bearings (bearings having two rolls of balls that revolve around the ball path) and bearings having more than a double row of balls. The single row ball bearings are further broken down into the maximum or full capacity type or the non-filling (Conrad) type. The ten digit classification for the Conrad type bearings is dependent on the outside diameter of the bearing. For tariff purposes, flanges and other projections from the outside surface of the outer race or ring are not included in the measurement of the outside diameter.

More infomation about tungsten carbide ball bearing, click here:

http://news.chinatungsten.com/en/tungsten-information/78745-ti-10022

http://news.chinatungsten.com/en/tungsten-information/78750-ti-10023

http://news.chinatungsten.com/en/tungsten-information/78796-ti-10032

http://news.chinatungsten.com/en/tungsten-information/78797-ti-10033

http://news.chinatungsten.com/en/tungsten-information/78843-ti-10039

http://news.chinatungsten.com/en/tungsten-information/78844-ti-10040

http://news.chinatungsten.com/en/tungsten-information/78892-ti-10051

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Ball Bearing VII

- Details

- Category: Tungsten Information

- Published on Wednesday, 23 September 2015 17:11

- Written by xiaobin

- Hits: 359

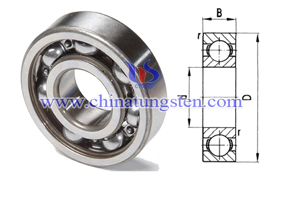

Radial Ball Bearings:

Radial ball bearings are the most common and most widely used ball bearing due to their versatility and durability. There are two basic types of radial ball bearings: the non- filling or Conrad type and the filling slot or maximum capacity type. The inventor of the Conrad type bearing assembly procedure, Robert Conrad, was given British patent no. 12,206 in 1903 and U.S. patent no. 822,723 in 1906.

This method of construction places an inner ring inside of the outer ring. With the rings aligned in the same direction, the inner ring is positioned so that it touches the outer ring at one point. This creates a crescent-shaped open area where an appropriate number of balls are placed. The inner ring is then snapped back to its original position in relationship to the outer ring. The balls are evenly distributed around the raceway, and the retainer is assembled into place. Most radial ball bearings are assembled using the Conrad method of construction.

More infomation about tungsten carbide ball bearing, click here:

http://news.chinatungsten.com/en/tungsten-information/78745-ti-10022

http://news.chinatungsten.com/en/tungsten-information/78750-ti-10023

http://news.chinatungsten.com/en/tungsten-information/78796-ti-10032

http://news.chinatungsten.com/en/tungsten-information/78797-ti-10033

http://news.chinatungsten.com/en/tungsten-information/78843-ti-10039

http://news.chinatungsten.com/en/tungsten-information/78844-ti-10040

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Basic Applications of Tungsten Carbide BurrsⅡ

- Details

- Category: Tungsten Information

- Published on Wednesday, 23 September 2015 15:33

- Written by zhihua

- Hits: 384

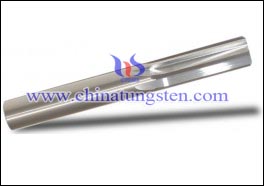

In last part we revealed that Tungsten carbide, in different shapes such as round, cylindrical and oval, and with different cuts, single or double, are used for rapid removal of excess materials, or of burrs from jagged, sharp edges, and also used prior to polishing or finishing with coated abrasives when usually the work pieces can be steel, cast iron, aluminum, etc., of which a die grinder is an example.Here we talk about the carbide burrs’ application in cylinder head porting and sculpturing.

Porting is another method in which application of the carbide burr is necessary. Cylinder head porting refers to the process of modifying the intake and exhaust ports of an internal combustion engine to improve the quality and quantity of the gas flow. Porting the heads provides the finely detailed attention required to bring the engine to the highest level of efficiency. Theoretically, polishing with abrasives affects the fuel flow and ultimately the porting process is responsible for the high power output of modern engines (Cylinder Head Porting June 2008).

Lastly, another common application and use of the tungsten carbide burr is utilized by sculpture. They provide vibration-free cutting and grinding. The shank is made of high tensile stainless steel. Diamond burrs are created by bonding diamond particles by means of electroplating with uniform size and exceptionally sharp-edged for fast cutting. Carbide burrs are precision fluted and can cut just about any material such as bronze, brass, aluminum, steels, wood, and all types of stone.

(----The end. This article is divided into 2 parts and here is part 2. For part 1 please refer to:http://news.chinatungsten.com/en/tungsten-information/78877-ti-10048 )

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten A Strategic Metal

- Details

- Category: Tungsten Information

- Published on Wednesday, 23 September 2015 16:54

- Written by yanna

- Hits: 286

In 1913,the British mining interests had no use for tungsten considered it a nuisance because it made tin extraction more difficult. But as World War І began, military and economic experts assured each other and the world that Germany could not keep up its industrial pace,and that its ammunition supply would be exhausted in six months.But it was soon discovered that Germany was increasing its munitions output,even exceeding that of the Allies.Germany's top-secret then was the use of tungsten high-speed steel in cutting tools.And the ore,the British found out later,had been coming from their own Cornwall mines.

With this impetus,due to demands of military might,world production of tungsten had leaped by 1916 to 23,104 short tons of concentrates. Only nine years before it had been6135 short tons-an amount in those days considered surplus.

Tungsten was establish as a strategic military item in the munitions race of World War І,but the military requirements for this metal became astronomical during World War Ⅱ with the introduction by the Germanys of a tungsten carbide armor-piercing shell.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Basic Applications of Tungsten Carbide BurrsⅠ

- Details

- Category: Tungsten Information

- Published on Wednesday, 23 September 2015 15:28

- Written by zhihua

- Hits: 350

Tungsten carbide burrs are used for rapid removal of excess materials. Ironically, burrs are both referred to as the excess shavings of material and the actual carbide burr tools used to remove rough edges after the machining process. The removal of burrs from jagged, sharp edges is another common application for carbide burrs. In addition, carbide burrs are a supplemental type of tool that is used prior to polishing or finishing with coated abrasives. Tungsten carbide burrs can be used on cast iron, steel and aluminum. Depending on the type of surfaces that are accessible, carbide burrs can be utilized because of the different shapes in which they are manufactured. Typically, carbide burrs are made in inch diameter shapes such as round, cylindrical and oval. Carbide burrs are created with different cuts. Single or double cuts are used for steel and cast iron surfaces. According to Monroe (1997, p. 28), a course single cut minimizes the tendency of the cutter to load up with aluminum.

A die grinder is a handheld tool which turns a burr at a high rate of speed. It is usually pneumatic (powered by compressed air), although electric die grinders are also common. The burr is held in a bit holding device and may be changed as required. The rotational speed of a pneumatic die grinder is adjusted by a hand-operated throttle which allows the operator to fluctuate the volume of compressed air entering the tool. Die grinders are used to drudge away small amounts of metal from piece of work. The name comes from their use in touching up hardened steel dies.

Most die grinder throttles feature a spring-loaded “kickstand” mechanism between the throttle lever and the body of the grinder, which prevents the throttle from opening (being pressed down towards the body of the grinder) without operator intervention. This prevents the die grinder from accidentally activating.

(----to be continued. This article is divided into 2 parts and here is part 1.For part 2 please refer to: http://news.chinatungsten.com/en/tungsten-information/78879-ti-10049)

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email:sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com