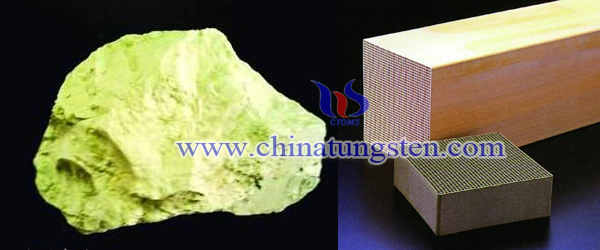

Palygorskite Based Tungsten Trioxide Denitration Catalyst

- Details

- Category: Tungsten Information

- Published on Friday, 20 May 2016 18:13

- Written by chunyan

- Hits: 245

| Tungsten Oxide Supplier: Chinatungsten Online www.tungsten-oxide.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Alloy Ionizing Radiation Shielding

- Details

- Category: Tungsten Information

- Published on Friday, 20 May 2016 17:58

- Written by minghui

- Hits: 265

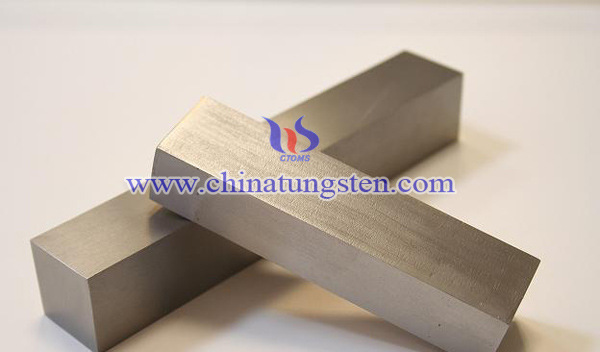

In fact, there are many kinds of radiation in our life. But experts point out that the radiation which causes damage to the human body to the greatest extent is ionizing radiation. Ionizing radiation refers to a high-energy radiation with short wave length and high frequency, which can directly or indirectly ionize the atoms and molecules of matter by interacting with the matter. The ionizing ability of ionizing radiation depends on the energy carried by the rays, if the rays did not bring enough ionization energy, the ionization can not occur. With the development of radiation technology, the application of ionizing radiation in our life is increasingly widespread. In the nuclear industry, it is used in the mining, smelting and finishing of raw materials, as well as the production, use and research of nuclear reactors and fuel; in agriculture, it is used for cultivation of new varieties, the preservation of fruits and vegetables and food storage; in medicine, it is used in disease diagnosis, cancer therapy and radiography; in industry, it is used for ray generator, electronic speed welder and various accelerators.

In fact, there are many kinds of radiation in our life. But experts point out that the radiation which causes damage to the human body to the greatest extent is ionizing radiation. Ionizing radiation refers to a high-energy radiation with short wave length and high frequency, which can directly or indirectly ionize the atoms and molecules of matter by interacting with the matter. The ionizing ability of ionizing radiation depends on the energy carried by the rays, if the rays did not bring enough ionization energy, the ionization can not occur. With the development of radiation technology, the application of ionizing radiation in our life is increasingly widespread. In the nuclear industry, it is used in the mining, smelting and finishing of raw materials, as well as the production, use and research of nuclear reactors and fuel; in agriculture, it is used for cultivation of new varieties, the preservation of fruits and vegetables and food storage; in medicine, it is used in disease diagnosis, cancer therapy and radiography; in industry, it is used for ray generator, electronic speed welder and various accelerators.

When the body is exposed to ionizing radiation whose doses exceed a certain limit, ionizing radiation can cause harm to humans. Ionizing radiation can cause radiation sickness, and lead to the pathological changes in almost all the organs and systems, the most obvious is the blood-forming organs, nervous system and digestive system. Ionizing radiation damage can be divided into acute radiation injury, which caused by receiving a certain dose of radiation in a short time and commonly found in the nuclear accident and the patients treated by radiation therapy, and chronic radiation injury, which caused by receiving scattered dose of radiation in a long time (such as skin damage, hematopoietic disorders, leukopenia, impaired fertility, etc.). In addition, ionizing radiation can also cause cancer and fetal death and malformations. Therefore, the use of protective measures is necessary.

Protective measures include placing a shielding between human body and sources of ionizing radiation to weaken the strength of the ionizing radiation. Since tungsten alloy has the advantages of high density, good machinability, good corrosion resistance and high radiation absorption capacity, tungsten alloy is the best choice for radiation shielding. Reducing the volume and the thickness of tungsten alloy shielding, its shielding ability is still equivalent to lead shielding. In addition, tungsten alloy shielding is non-toxic non-polluting, so that it is easier for people to accept.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Hollow Drill Description

- Details

- Category: Tungsten Information

- Published on Friday, 20 May 2016 17:37

- Written by xiaobin

- Hits: 252

Tungsten carbide hollow drill mainly composed of the refractory metal carbide WC and the binder phase Co, which is also called as coring drill, center drill, punch drill and so on. It is one type of tungsten carbide drills, except the hollow drill, there are cone bit, drill with indexable inserts and tungsten carbide acicular drill, etc. Tungsten carbide drill breaks the rocks through the impact load produced by the drilling pressure and rotation itself. In the process of rock drilling, the drill bit is subjected to high frequency impact load, and by twisting, bending, stretching, compression and other complex stress, and in the high-speed rotation of the environmental impact is subjected to rock, rock dust and wear and corrosion mineral water.

For the highly abrasive formations, autogenous tungsten carbide acicular drill can be used. Usually hard alloy drill drilling rock drillability is Ⅶ grade Ⅱ formation; tungsten carbide drill bits drilling Ⅵ Ⅷ stage rock. Tungsten carbide hollow drill mostly used for cutting, drilling, annular groove processing, which can be widely used in rail, construction, machinery, aerospace, bridges, ships and other processing areas. It has high drilling efficiency, flexible operation and can be used with other types of drills and achieve multifaceted process, and the drilling performance is remarkably better than the conventional twist drill.

Tungsten carbide hollow drill mainly includes the following grades:

1. YG3X HRA ≥91.5 cobalt tungsten titanium in the best wear resistance, but poor impact toughness, suitable for cast iron, nonferrous metals and alloys, broken fire steel, alloy steel small section of high-speed finishing;

2. YG3 HRA ≥90.5 wear resistance second only YG3X, more sensitive to shock and vibration, for cast iron, nonferrous metals and alloys continuous cutting of fine cars, semi-finishing and processing, fine threading and reaming;

3. YG6A HRA ≥91.5 case of fine-grained alloy, good wear resistance, suitable for cooled cast iron, nonferrous metals and other semi-finished alloy is also suitable for broken fire steel alloy steel semi-finishing and finishing;

4. YG6 HRA ≥90 high wear resistance, but less than YG3, shock and vibration is better than YG3X. For cast iron, nonferrous metals and alloys, non-metallic materials medium cutting speed semi-finishing and finishing;

5. YG8 HRA ≥89.5 use of high strength, impact resistance, shock resistance compared YG6 good, but lower wear resistance and allow the cutting speed. For cast iron, nonferrous metals and alloys, non-metallic materials at low cutting speed.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Tungsten Carbide Hollow Drill Comparison

- Details

- Category: Tungsten Information

- Published on Friday, 20 May 2016 17:39

- Written by xiaobin

- Hits: 272

Besides, hollow drills also use high-speed steel and tool steel. Although high-speed steel and tool steel is more sharp and high drilling efficiency, but it is easy to brittle fracture when drilling high hardness materials. And at this point carbide has better strength and wear and corrosion resistance, not prone to chipping in some of the harder material when drilling in environmental corrosive liquid can be ensured under the drilling work stably performed. Tungsten carbide hollow drill blade portion generally use a combination of three blade structure, ranging from pitch division, there are some special combination of edge structures using a plurality of outer edges of the blades and the inner edge components. Each blade in the cutting process, the work load is only about 1/3, and with the inside of each blade are also cutting, making very smooth chip evacuations.

In addition, since each edge can endure parts of cutting work, its drill holes extremely difficult to be broken. Tungsten carbide hollow drill can drill 50mm in thickness of steel plate at high-speed with high-precision and drilling can be overlapped. With a dedicated core drill machine is also capable of multi-directional drilling, cutting light, high efficiency, bit life long, relatively low cost, suitable for all types of drilling, milling machines, lathes and so on.

Here are some notes on tungsten carbide hollow drills:

1. Before the start of the drilling must ensure that the tool is fully seated, no loose or clamping;

2. It must be ensure that when using the magnetic base drilling rig drilling rig at no iron magnet, suction surface smooth, no machine or swing adsorption phenomena completely;

3. The whole process start drilling until the completion of the drilling should be kept cooled sufficiently, the best use of the cooling conditions, inadequate cooling can lead to damage of the tool.

4. Drilling should start slow and steady feed, cut into the 1-2mm can speed up the feed rate. When appropriate to slow down the knife cutting speed, the cutting process intermediate feed should be kept stable;

5. Tungsten carbide is a kind of materials with high hardness, and it is supposed to prevent the shock.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Rare Earth Tungsten Electrode Applies to High Intensity Discharge Lamps

- Details

- Category: Tungsten Information

- Published on Friday, 20 May 2016 16:26

- Written by yiping

- Hits: 251

Comparing the luminescent properties of rare earth tungsten electrode and thoriated tungsten electrode in different power lighting metal halide lamp and car halide found rare earth tungsten electrodes has similar properties with thoriated tungsten electrode , which can replace radioactive thoriated tungsten electrodes using in high intensity discharge lamps, not only environmental and having good performance.

Tungsten electrode is an important component of high-intensity discharge lamps. According to the functions can be divided into cathode and an anode. The cathode is to emit electrons at a certain temperature, so that the electrodes can move to the anode, and the anode receives electrons. In alternative current, the tungsten electrode is not only as the cathode, but as the anode. In the positive half cycle it is anode and in the negative half cycle it is cathode, so in the exchange discharge lamp the electrode will be referred as cathode. Rare earth tungsten electrode used in high-intensity discharge lamps, its performance is closely related to the discharge lamp life. So rare earth tungsten electrode as cathode material can meet the following requirements:

Tungsten electrode is an important component of high-intensity discharge lamps. According to the functions can be divided into cathode and an anode. The cathode is to emit electrons at a certain temperature, so that the electrodes can move to the anode, and the anode receives electrons. In alternative current, the tungsten electrode is not only as the cathode, but as the anode. In the positive half cycle it is anode and in the negative half cycle it is cathode, so in the exchange discharge lamp the electrode will be referred as cathode. Rare earth tungsten electrode used in high-intensity discharge lamps, its performance is closely related to the discharge lamp life. So rare earth tungsten electrode as cathode material can meet the following requirements:

1. Having low work function,

2. Having good arcing performance and arcing stability;

3. Having low evaporation rate, when meets the requirement of cathode material;

4. Having stable structure, small high-temperature creep strength, electron resistance and ion bombardment resistance;

5. Having stable chemical property, the electrode will not react with filler material of lamp;

6. High intensity discharge lamps operate at temperatures above 2000K, so the electrodes so have good high temperatures property.

Rare earth tungsten electrodes production processes are as following: mixing rare earth nitrate solution with tungsten oxide by solid-liquid doping method, after reduction to obtain mixed powder. After pressed, sintered the mixed powder can obtain the blank. Then to process a series of machining can obtain rare earth tungsten electrodes. There are two ways for rare-earth doping. One is the traditional solid-liquid doping method, which is to mix rare earth nitrate solution with tungsten oxide. The second is liquid-liquid doping method, which is more effective.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com