Thoriated Tungsten Electrode Second Phase Research after Machining Deformation

- Details

- Category: Tungsten Information

- Published on Wednesday, 18 May 2016 16:20

- Written by yiping

- Hits: 249

Thorium tungsten electrode after machining deformation, the second phase had some obvious different changes. By analyzing the second phase changes after recrystallization, 202 rotary swaging and finished electrode, understand the impact of deformation on second phase of electrode.

After recrystallization, more second phase of thorium tungsten electrode had maintained spherical shape and small showed elongated rugby-ball like shape, or broken. This is mainly because a lot of residual stress disappeared after recrystallization annealing, so the internal stress of the electrode was in equilibrium, and tungsten matrix grains in the recovery and recrystallization process, the second phase showed spherical shape. Spherical shape is in favor of reducing electrode stress, in subsequent processing to prevent internal cracks. In addition, the spherical shape of second phase can be better deformation with the tungsten matrix to improve the mechanical properties of the electrode. Meanwhile, spherical second phase distribution in grain boundaries of tungsten matrix can effectively inhibit the cracks expansion in grain boundary.

And small second phase showed rugby-ball like mainly because during hot rolling cogging there were excessive external force, making the second phase not time moved to tungsten matrix, but it creates plastic deformation. Besides, there was fragmentation in the axial direction.

After 202 rotary swaging, the second phase elongation along with axial direction and most showed rice-like shape. When the deformation isn’t large, it can still maintain the ability to deformation with tungsten matrix. And a part of the second phase particles will be broken, mainly because deformation increased and deformation temperature reduced, so tungsten matrix deformation capacity will gradually decrease. And recovery and recrystallization grains will gradually shift to the dislocation cells, then if the second phase affected by the significant external force will occur fragility fracture.

With the deformation increased, tungsten matrix showed significant fibrous tissue. The second phase particles interrupted distributed in tungsten matrix with fibrous tissue. With the degree of deformation increased, the deformation ability has been behind the tungsten matrix, and easy to occur brittle fracture. Making rice-like second phase broke into smaller particles while leaving a large hole, which is not suitable for further processing. Otherwise it will generate a lot of cracks.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Thoriated Tungsten Electrode Microstructure Research after Machining Deformation

- Details

- Category: Tungsten Information

- Published on Wednesday, 18 May 2016 16:16

- Written by yiping

- Hits: 234

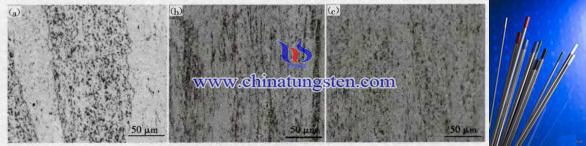

To obtain thoriated tungsten electrode should process a series of machining deformation processing on tungsten blank. Machining deformation of thorium tungsten electrode mainly includes swaging cogging, recrystallization annealing, 203 rotary swaging, 202 rotary swaging, 201 rotary swaging, drawing, straightening, polishing, and finally be finished. Selected three typical stages in the whole process analyze thorium tungsten electrode microstructure change, which were sampled in three stages of recrystallization annealing, 202 swaging and finished products.

After recrystallization annealing, tungsten matrix of thoriated tungsten electrode had very obvious grain boundaries, and along the axial direction grain boundaries was relatively flat. Besides, the grains of tungsten matrix were thicker and had certain of extension. There were many fine black spherical particles in electrode internal, which is the second phase.

After 202 rotary swaging, the grains of tungsten matrix became slender, and had clearer boundaries. Different with recrystallization stage, there was a certain fibrotic. The grains of tungsten substrate along the axial direction to extent, the coarse grains became long and thin. What’s more, the second phase distributed more evenly, but still maintained a spherical or near spherical shape.

With deformation increasing, the grain boundary of tungsten matrix in finished thoriated tungsten electrode gradually became blurred, and the crystal grains completely replaced by fibrous tissue. Fibrous tissue elongates along with the axial direction of the electrode. The second phase particles distributed more evenly.

From the above analysis, thorium tungsten electrode during machining deformation, with increasing deformation, the tungsten matrix gradually turns to fibrosis and distribution of second phase particles becomes more uniform. Besides, the second phase is mainly composed of Th, O and W three elements.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Rising Price of Tungsten Material Is Becoming a Hot Trend

- Details

- Category: Tungsten Information

- Published on Wednesday, 18 May 2016 10:52

- Written by xuejiao

- Hits: 263

Because that tungsten has unique physical and chemical characteristics, it has become one of the indispensible materials in the field of modern industry, national defense and science and technology. Tungsten material industry is a branch of non-ferrous metals industry whose industrial chain includes exploration, mining, smelting, tungsten material processing, marketing and other aspects of wolfram. From a worldwide perspective, currently, it is mainly applied in carbide, steel and alloys, tungsten processing materials, chemicals and others.

China is one of the largest tungsten reserves countries in the world, and its tungsten reserves is 5.2 million tons. What’s more, its production and export volume rank the first position in the world. After years of rapid development, The scale of the production of wolfram of China mining is continuously enlarge, technology development capability, competitiveness of the market has reached a certain level. However, because tungsten is non-renewable resources, cheap, and the irrational exploitation by domestic factories, in addition, the cost of wolfram mining is continuously rising, coupled with the domestic industrial market still keep depressed condition, the domestic sales of wolfram raw material is still tight, so rising price of wolfram material has become a hot trend, and the price of related products of wolfram also continued increases.

Among them, in terms of tungsten concentrate, price of 65% wolframite is 7.9 yuan / ton, compared with the average price of last week it rose 1000 yuan / ton. Price of 65% scheelite concentrate is 7.7 yuan / ton, compared with the average price of last week it rose 1000 yuan / ton.

Among them, in terms of tungsten concentrate, price of 65% wolframite is 7.9 yuan / ton, compared with the average price of last week it rose 1000 yuan / ton. Price of 65% scheelite concentrate is 7.7 yuan / ton, compared with the average price of last week it rose 1000 yuan / ton.

For the ammonium paratungstate (APT), its price is 12.8 yuan / ton, compared to the average price of last week, it rose 3,000 yuan / ton.

In the aspect of powder, the price of medium-sized particles of tungsten carbide powder is 192 yuan / kg, the price of tungsten powder is 194 yuan / kg, compared with the average price to the last weekend, and it rose 5 yuan / kg.

For # 1 tungsten rod (≥99.95%), the price is 245 yuan / kg, compared to the average price over the last weekend it rose 5 yuan / kg. Influenced by the global steel overcapacity, the price of steel in the last month has a continuous fall, which has shock many iron and steel businesses.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Testing Standard of Carbon Sulfur Analyzer and Tungsten Granule——Technical Requirements

- Details

- Category: Tungsten Information

- Published on Wednesday, 18 May 2016 10:55

- Written by xuejiao

- Hits: 219

Generally speaking, carbon sulfur analyzer refers to the generic terms of the instruments which are used to analyze the content of carbon and sulfur of the ferrous metallic material. This type of equipment is easy to operate, with the efficient and high-precision analysis results and other excellent characteristics. It is widely used in the detection of carbon, sulfur and sulfur dioxide content of metals, minerals, ceramics and other substances. The working principles of the instrument are follows: tungsten granule is added to the a certain weight sample as a flux, and then placed in a high-frequency heating furnace for a high temperature combustion, carbon and sulfur of samples will react with oxygen, then produce carbon dioxide and sulfur dioxide, entering to the testing room of carbon dioxide and sulfur dioxide through the gas path system with the carrier gas, and then analyze the content of carbon dioxide and sulfur dioxide by using the measured light intensity absorption. Finally, the data obtained content of carbon and sulfur. The whole machine adopts modular design, power supply system consists of two modules, which can avoid dust, and it is simple and reliable.

Testing standards of carbon sulfur analyzer and tungsten granule mainly consists of five parts: the technical requirements, test conditions, methods of identifying, management of the results of treatment as well as the re-testing period. In appearance of the instrument, it should be marked with the name of instrument, model number, manufacturer's name, license logo and number of manufacturing measuring instruments, date of manufacturing as well as the number of instruments. The appearance of the instrument cannot have any mechanical damage, and each member should be in a solid state, the function keys are intact, which is able to work properly.

For different measuring range, the error of the average value and standard value of the testing results cannot exceed the standard requirements. The indicating error of carbon content which is more than 0.0010 to 0.0100 is ± 0.0005%, the indicating error which is between 0.010 to 0.100 is ± 0.005%, and error of indication between the 0.100 to 1.000 is ± 0.010%, indication error between 1.00 to 3.00 is ± 0.03%. The standard of sulfur content is the same as the carbon content, the different is that the error of indication of sulfur between 0.100 ~ 0.300 is ± 0.010%.

| Tungsten Metals Supplier: Chinatungsten Online www.tungsten.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

The Advantages Of Tungsten Alloy Shielding

- Details

- Category: Tungsten Information

- Published on Wednesday, 18 May 2016 09:51

- Written by minghui

- Hits: 251

With the rapid development of technology and the wide application of radiation technology, the harm of radiation gradually aroused people's concern. In physics, radiation is the emission or transmission of energy in the form of waves or particles(such as alpha particles, beta articles)through space or through a material medium. It is generally divided into ionizing radiation and non-ionizing radiation depending upon the energy of the radiated particles and can cause harm to humans. Long-term radiation exposure will cause the body unwell, serious can damage human body organs and systems, causing various diseases (such as leukemia, cancer, aplastic anemia, retinal disease, reproductive system disease, premature aging, etc.). The main methods of radiation protection include protection of time, distance and shielding protection. Wherein the shielding protection is to place a shielding which can effectively absorb radiation between the radiation source and the human body. The common used shielding materials are lead, tungsten alloy and boron carbide.

With the rapid development of technology and the wide application of radiation technology, the harm of radiation gradually aroused people's concern. In physics, radiation is the emission or transmission of energy in the form of waves or particles(such as alpha particles, beta articles)through space or through a material medium. It is generally divided into ionizing radiation and non-ionizing radiation depending upon the energy of the radiated particles and can cause harm to humans. Long-term radiation exposure will cause the body unwell, serious can damage human body organs and systems, causing various diseases (such as leukemia, cancer, aplastic anemia, retinal disease, reproductive system disease, premature aging, etc.). The main methods of radiation protection include protection of time, distance and shielding protection. Wherein the shielding protection is to place a shielding which can effectively absorb radiation between the radiation source and the human body. The common used shielding materials are lead, tungsten alloy and boron carbide.

Boron carbide (chemical formula approximately B4C) is an extremely hard boron–carbon ceramic, and covalent material used in tank armor, bulletproof vests, engine sabotage powders, as well as multitudinous industrial applications. The ability of boron carbide to absorb neutrons without forming long-lived radionuclide makes it attractive as an absorbent for neutron radiation arising in nuclear power plants and from anti-personnel neutron bombs. Lead is a soft, malleable and heavy post-transition metal. It is used in building construction, lead-acid batteries, bullets and shot, weights, as part of solders, fusible alloys, and as a radiation shielding. However,if ingested or inhaled, lead and its compounds are poisonous to animals and humans. Lead is a neurotoxin that accumulates both in soft tissues and the bones, damaging the nervous system and causing brain disorders.

Compared to lead and boron carbide radiation shielding materials, tungsten alloy radiation shielding provides excellent density with small capacity. At the same weights greater density tungsten alloy can provide the same energy absorption as lead using 1/3 less material. When the weight is certain, greater density, and the thickness would be thinner. Tungsten alloy radiation could be made with thinner thickness but high absorption of radiation in great density. That is why tungsten alloy material is suitable for tungsten alloy radiation shielding.

| Tungsten Alloy Supplier: Chinatungsten Online www.tungsten-alloy.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com