CVD Diamond Coated Carbide Pretreatment—Transition Applied (1/2)

- Details

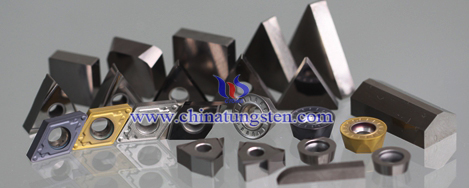

- Category: Tungsten Information

- Published on Thursday, 21 January 2016 16:58

Except acid etching and plasma etching to remove cobalt (Co), deposited a transition layer between diamond film and tungsten carbide cutting tool in advance is also a common kind of pretreatment. At present, common types of transition layer can be specifically divided into single-layer transition and composite transition. Single-layer transition includes silicon (Si), chromium (Cr), boron (B), copper (Cu), titanium (Ti), silicon carbide (SiC), silicon nitride (Si3N4), silicon carbide, nitrogen (SiCxNy), titanium nitride (TiN), titanium carbide (TiC), titanium carbonitride (TiCN), (Ti, Si) Nx, diamond-like carbon coating (DLC) and so on; composite transition layer includes tungsten carbide / tungsten (WC / W), titanium carbide / titanium nitride (TiC / TiN), titanium nitride / titanium carbonitride / titanium nitride (TiN / TiCN / TiN), titanium carbonitride / titanium (TiCN / Ti ), chromium / chromium nitride / chromium (Cr / CrN / Cr), and copper / titanium (Cu / T), etc.

There are many effects of the transition layer, such as it blocks out the diffusion of Co, which promotes the growth of graphite in carbon and the matrix; secondly, it decreases the possibility of heat stress appearing caused by the mismatching of crystal lattice parameters and coefficient of thermal expansion between diamond coating and tungsten carbide matrix, thirdly, the transition layer not only can improve the binding force between traditional diamond film and tungsten carbide matrix, but also form a bond of conjunction with two different kinds of materials; and it can increase the density of nucleation of diamond (nucleation, the process of under cooling metal liquid, which is the initial stage of crystallization.) and the binding force of diamond film; last but not least, the transition layer has stable chemical properties and excellent mechanical strength.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com