Tungsten Crucible Plays a Key Role in the Rare Metal Smelting

- Details

- Category: Tungsten Information

- Published on Monday, 09 June 2025 15:01

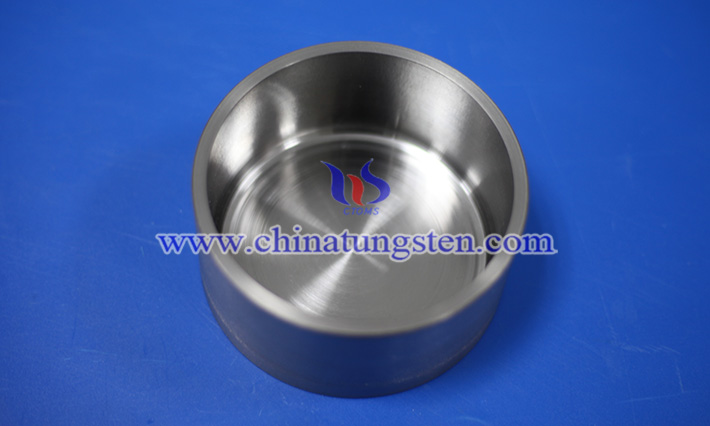

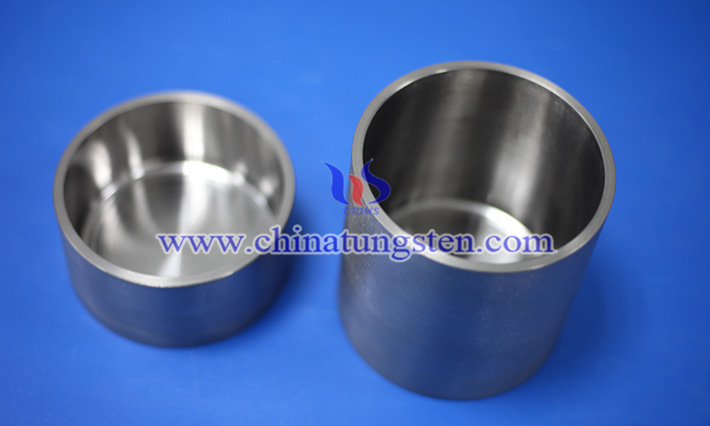

Tungsten crucible, as a high-temperature container made of high-purity tungsten material, plays an irreplaceable key role in the field of rare metal smelting due to its excellent high temperature resistance, chemical stability and mechanical strength.

With the continuous expansion of rare metal applications, such as aerospace, semiconductors, special alloys and new energy materials, its importance in high-temperature smelting is becoming increasingly prominent.

Tungsten has an extremely high melting point, one of the highest of any known metal. In the process of rare metal smelting, high-temperature melting is often required in a vacuum or inert atmosphere, which places extremely high demands on the heat resistance and chemical inertness of the crucible material. Crucibles made of tungsten can not only withstand high temperatures without softening or deformation, but also show strong corrosion resistance in most metal melts, and are not easy to chemically react with the smelted metal, ensuring the purity of the smelting process and the consistency of the product.

Crucibles made of tungsten are widely used in the melting and crystallization process of rare metals with high melting points, such as rhenium, tantalum, hafnium, titanium, zirconium, etc., especially in high-temperature processes such as electron beam melting (EBM), plasma melting (PAM) and induction melting. Compared with graphite crucibles, it has advantages in terms of no carbon pollution, oxidation resistance and thermal stability, and is especially suitable for smelting environments with extremely high purity requirements.

In addition, W crucibles have important uses in crystal growth, precision metallurgy, and material preparation. For example, in functional crystal growth processes such as sapphire, gallium oxide and yttrium aluminum oxide (YAG), it can be used as an ideal melt container to ensure a stable crystal growth environment while avoiding the incorporation of impurities.

In practice, tungsten crucibles usually need to be operated under vacuum or inert gas protection to prevent oxidation at high temperatures. At the same time, its manufacturing accuracy is required to be high, and it is necessary to use isostatic pressing, machining or tungsten powder sintering and other processes to ensure that the inner wall is smooth and the size is accurate, so as to meet the strict control of thermal field distribution and flow state in the smelting process.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com