Tungsten Contacts Corrosion

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 July 2015 16:00

The main factors affecting the corrosion rate of tungsten contacts corrosion are: impurities of air, humidity and metal surfaces state. If the humidity in the air is greater, the condensation of the water film on the metal surface will be thicker, so the resistance of the water film will be smaller, the corrosion will faster.

The chemical reaction formula of tungsten contacts corrosion process is as follows

W + O2 = W - 4e + O2 = WO2

2WO2 + H2O – e = W2O5 + 2H

W2O5 + H2O - e = 2WO3 + 2H

WO3 + H2O = H2WO4(black gum)

H2WO4 – H2O = WO3(dehydration → tan dura)

As can be seen from the above formula, the nature of the electrochemical corrosion, which is the process of the metal atom loses electrons and be oxidized.

Electrochemical corrosion referring to the process that metal and the electrolyte have an electrochemical reaction so that the metal is destroyed.

Metal electrochemical corrosion conditions:

1. There is potential difference between metals

2. Reaction takes place in the electrolytic liquid, etc.

Tungsten contacts will corrode in humid (usually, it occurs when air humidity is greater than 60%), and is called atmospheric corrosion, which is a kind of electrochemical corrosion. Atmospheric corrosion occurs on the electrolytic film layer of the metal (dissolved a variety of salts and corrosive gas impurities), the formation of the film is due to water vapor in the atmosphere condensed or adsorbed on the metal surface.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Analysis of Tungsten Points Surface Film from its Electrode Potential

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 July 2015 15:57

Tungsten (W) is the main raw materials of tungsten points, that is to say, analysis of tungsten points’ surface film from its electrode potential is similar to the analysis of tungsten.

Each species owns the characteristic of standard electrode potential, which is a kind of equilibrium electrode potential.

The standard electrode potential at 25 ℃

|

Metal |

Ion |

Electrode potential (V) |

|

W |

W |

-0.2 |

|

Ni |

Ni2+ |

-0.23 |

|

Ag |

Ag+ |

+0.799 |

|

Cu |

Cu2+ |

+0.34 |

|

Pb |

Pb2+ |

-0.126 |

|

Fe |

Fe2+ |

-0.44 |

Standard electrode potential---put a matter in some kind of solution, which contains matter’s ions, the potential difference between the matter and the standard hydrogen electrode is the very standard electrode potential when ion concentration is 1g / L. The metal will be more active when negative value of standard electrode potential is bigger; but it will be less active when standard electrode positive value is larger.

What can be drawn from the table is that the potential difference between W and Cu is the biggest, which is 0.54V. The points’ material electrochemical corrosion is prone to appear in a high temperature, high humidity environment. Nevertheless the corrosion between W - Ni is slighter than W - Cu’s, W – Ag’s. Electrochemical corrosion is not prone to occur since the potential difference of W - Ni is only 0.03V, whose. Therefore, adding a right amount of Ni can improve oxidation resistance property of tungsten points, which will reduce the formation of its surface film.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Electrode Potential Analysis on Tungsten Contacts Surface Film

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 July 2015 15:56

The main content of tungsten contacts is tungsten (W), i.e. electrode potential analysis on tungsten contacts surface film can be available from tungsten analysis.

Standard electrode potential is a kind of equilibrium electrode potential, and each substance has this feature.

Standard electrode potential refers to: placing a substance in a solution containing its ions, if the ion concentration in the solution is 1g / L, the potential difference between the substance and standard hydrogen electrode is standard electrode potential. If negative value of standard electrode potential is bigger, the metal will be more active; If the positive value is larger, the metal will be less lively.

At the temperature of 25 ℃, the standard electrode potential of several metals table

|

Metal |

Ion |

Electrode potential (V) |

|

W |

W |

-0.2 |

|

Ni |

Ni2+ |

-0.23 |

|

Cu |

Cu2+ |

+0.34 |

|

Ag |

Ag+ |

+0.799 |

|

Fe |

Fe2+ |

-0.44 |

|

Pb |

Pb2+ |

-0.126 |

From the above table, which shows that the potential difference between the electrode W and Cu is 0.54V, in a condition of high temperatures and high humidity, the contacts material’s electrochemical corrosion is prone to appear. Whereas the phenomenon on W and Ni corrosion is more slight than W and Cu, W and Ag, because the potential difference between the electrodes W and Ni is only 0.03V, whose electrochemical corrosion is not easy to take place. So, the right amount of Ni can be added to tungsten contacts to increase its oxidation resistance capacity, that is to say, reducing the likelihood of its surface film formation.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

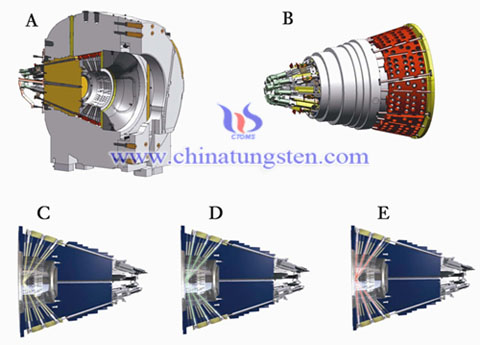

Tungsten Collimator Rings in Gamma Knife

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 July 2015 15:02

In a gamma knife machine, a total of 192 60Co sources are arranged in a cylindrical configuration in five concentric tungsten collimator rings. The radiation cavity has been increased by more than 300% compared to previous models. However, due to an improved collimation system (120 mm tungsten collimator rings), the average distance from source to focus is very close to previous models. This results in similar output for the prior 18mm and new 16 mm administrations. This differs substantially from the previous hemispherical arrangements and results in different source to focus distances for each ring varying from 374 to 433 mm. The primary and secondary collimators have been replaced by a single large 120 mm thick tungsten collimator rings.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Applications of Tungsten Polymer for Industry

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 July 2015 14:57

As its special high density of 11.34 g/cm3 min., tungsten polymer has a perfect radiation shielding performance comparable to lead for anti-radiation shielding, and it is much healthier. Besides, tungsten polymer is very easy to be cut or held with household scissors and so much formable into shapes with various curved surfaces.

Tungsten polymer can be used widely in industry, such as the radiation shielding for radiation detectors , and nuclear industry radiation protection. Tungsten polymer for shielding X-ray and gamma radiation including a full body apron and a thyroid guard are the first commercially available, it can greatly enhance both the material properties and the shielding efficiency.

Applications of Tungsten Polymer for Industry:

Nuclear logging radiation shielding

Welding inspection radiation shielding

Container inspection radiation shielding

Nuclear submarine radiation protector

Nuclear reactor radiation protector

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Mine Extraction

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 July 2015 14:25

Open-pit mining is used if near-surface ore body is massive or when it occurs in steeply-dipping lode(s), sheeted vein systems, pipes, or makes up the bulk of the country rock as in disseminated or prophyry-style deposits. The whole ore body is mined with no overburden being put back into the void during the extraction operation.

Some placer deposits are amenable to strip mining or dredging operations. In strip mining the overburden is removed and deposited in the hole left from the excavation of the previous strip or panel and the ore can be simply dug out. Hydraulic mining is commonly used in reclamation of old mine tailings that still contain payable values of tungsten.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Ore Resources

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 July 2015 14:20

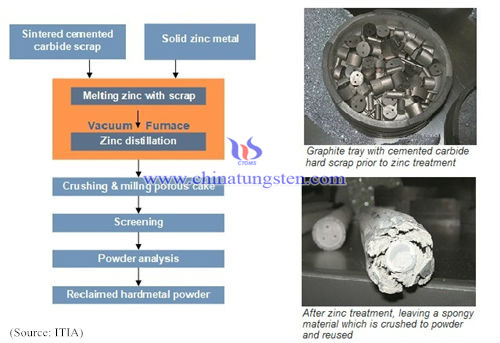

Tungsten ore has two levels standards. There is a distinction between primary tungsten (ore concentrates of wolframite and scheelite) and secondary tungsten (different types of tungsten containing scrap).

Primary Tungsten (Concentrate)

China is the major producer of primary tungsten. The other principal producing countries are Austria, Bolivia, Canada, Peru, Portugal, Russia, Thailand and several countries in Africa. Some mines which have closed in recent decades in Australia, South Korea and the USA are now considering re-opening. In addition, several new projects were started recently for exploration and exploitation worldwide, although the economic crisis towards the end of 2008 brought many to a stop.

Secondary Tungsten (Scrap)

Scrap recycling is an important factor in the world’s tungsten supply. It is estimated that today some 35% is recycled, and the tungsten processing industry is able to treat almost every kind of tungsten-containing scrap and waste to recover tungsten and, if present, other valuable constituents. Tungsten scrap, due to its high tungsten content in comparison to ore, is a valuable raw material.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Silicotungstic Acid Producing Processes

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 July 2015 14:14

Producing processes of silicotungstic acid are as follows:

1. Making 1000g hydrated sodium tungstate dissolved in 2000mL water.

2. Adding 75g water glass into the solution and the solution was stirred violently with a motor stirrer and heated to boil. At the same time, using a separatory funnel adds 600mL concentrated hydrochloric acid with dropwise.

3. Filtered off a small amount precipitate of silicic acid and cool the mixture. Then add 400mLconcentrated hydrochloric acid and cool the solution.

4. Extract by little excess ether which is washed with dilute sodium hydroxide solution. First, putting ether complex into a suction flask, washed air drawn into this mixture to blown off ether quickly, at the same time the mixture was heated on a hot pan. Continue this process until the upper edge liquid appears crystals. Then, the solution was left to be slowly crystallized, or the solution was evaporated to dryness. The complex was re-dissolved in water and then evaporated to dryness. Continue to repeat this operation until the product had no odor of volatile acids.

5. When fully dried, pulverized acid in a mortar and drying to constant weight at 70℃.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

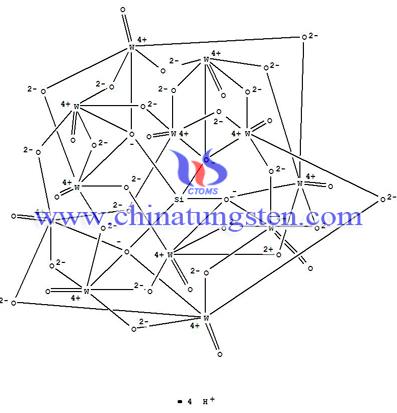

Silicotungstic Acid

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 July 2015 14:11

Silicotungstic acid also known as dodeca-tungstosilicic acid tungstosilicic is white or yellowish deliquescent crystals. Its physical properties are shown below: chemical formula: H4O40SiW12, molecular weight: 2878.17, Solubility: 0.1g/ml (in water), CAS registry No.: 12027-38-2. Silicotungstic acid easily solute in water and alcohol, after dissolved the the solution is clear and transparent, but when it heat will dissolve in its crystal water and heated to 600~650℃ will decomposition. H4O40SiW12 mainly used in biochemical reagents and basic dye mordant. To seal and placed in dry place when storage and transportation.

Silicotungstic acid producing processes are as follow: using ammonium paratungstate as raw material, after conversion, mix silicon, exchange, evaporation and concentrated and other processes to obtain products, thereby preparing silicon tungstate. This producing method processes are reasonable and products have good quality, what’s more, it is kind of non-polluting method. It will be a new road for non-ether produced silicotungstic acid and silicon tungstate.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Ore Processing-Concentrates (Primary Tungsten Sources)

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 July 2015 13:53

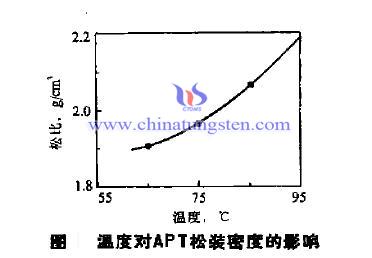

Tungsten ore obtains cheelite and wolframite. Modern processing methods dissolve scheelite and wolframite concentrates by an alkaline pressure digestion, using either a soda or a concentrated NaOH solution. The sodium tungstate solution obtained is purified by precipitation and filtration, before it is converted into an ammonium tungstate solution. This stage is carried out exclusively by solvent extraction or ion exchange resins. Finally, high purity Ammonium-Paratungstate (APT) is obtained by crystallisation, with the formula (NH4)10(H2W12O42) ·4H2O.

Wolframite concentrates can also be smelted directly with charcoal or coke in an electric arc furnace to produce ferrotungsten (FeW) which is used as alloying material in steel production. Pure scheelite concentrate may also be added directly to molten steel.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com