Electrical Life Research on Tungsten Copper Points

- Details

- Category: Tungsten Information

- Published on Tuesday, 28 July 2015 17:44

What decide appliances’ electrical life? The electrical wear of it determined. The electrical life of tungsten copper points’ is determined by the density, melting point and conductivity of its raw material.

There are three phase process (sophisticated phase, stable phase and failure phase) of tungsten copper points’ electrical wear. Among which the length of stable phase time is acting as a decisive role on points’ materials electrical life. Only when the binder phase’s component, copper and tungsten skeleton in points’ material, whose mass ratio is controlled in a certain extent, can the electrical wear time of points’ material stable stage could maintain the longest.

Points’ materials electrical wear, during its opening and closing process, which mainly owning to the arc and other thermal effects, making copper surface melting, vaporizing and splashing, leading to the rest skeleton materials, due to recrystallization, crystal growth, friction and wear, will break down soon in the subsequent process.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

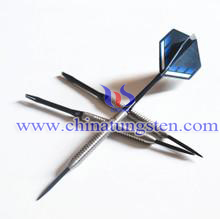

Golf Tungsten Dart RuleⅡ

- Details

- Category: Tungsten Information

- Published on Tuesday, 28 July 2015 17:44

Golf: Golf is a game that may be played with as many players as desired. It is also a very quick game, limited to only 3 "shots" per "hole". Games may be played with 9 or 18 holes. A 9 hole game with 2 players can be played in 5 minutes or less.

The Play: The first player begins the first hole by throwing for 1's. The player may choose to throw one, two or all three darts for the hole. However many darts are thrown. The last dart thrown is the one that counts. For example, the player throws the first dart into the thin wedge of the 1 for a score of 3. Un-satisfied with this score, he throws the remaining two darts at the triple and misses the ones entirely. His score for is now 5 for the hole, he may not choose to count the first dart because he continued throwing. If he had been satisfied with the first dart, he may have kept the score of three and not thrown the remaining two darts.

The remaining players play through the first hole in order. When play returns to the first player, the second hole is played and 2 is the target number. The game continues as such until all 9 or 18 holes have been played.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Golf Tungsten Dart RuleⅠ

- Details

- Category: Tungsten Information

- Published on Tuesday, 28 July 2015 17:42

Golf: Golf is a game that may be played with as many players as desired. It is also a very quick game, limited to only 3 "shots" per "hole". Games may be played with 9 or 18 holes. A 9 hole game with 2 players can be played in 5 minutes or less.

The Object: Like real golf, the object is to complete each hole in as few shots as possible. The player with the lowest score at the end of 9 or 18 holes wins.

The Scoring: Players names are written across the top of the board in order. Order is usually determined by throwing one dart each for the bullseye with the closest playing first. This is a game that playing order makes no difference, all players have an equal number of throws to complete the game.

The agreed upon number of holes to play is written in order down the left side of the board (1 through 9 or 1 through 18). A running total is kept for each hole played and written next to the number of the hole in the column for that player.

The thin outer "doubles" ring counts as a hole in one. The thin inner "triples" ring counts as 2 strokes. The thin wedge between the bulls-eye and the triples ring counts as 3 strokes. The thick wedge between the doubles and triples ring counts as 4 strokes. Missing the number entirely counts a 5 strokes. 5 is the worst score you can score on any one hole.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Manganese Tungstate

- Details

- Category: Tungsten Information

- Published on Tuesday, 28 July 2015 16:16

Besides, at low temperature manganese tungstate is the anti-ferromagnetic materials and English alias is manganese (II). Its physical properties are as follows: chemical formula: MnO4W, molecular weight: 302.78, density: 7.324g/ml, Solubility: insoluble, CAS registry number: 14177-46-9, MDL number: MFCD00014212. MnO4W is stable at room temperature and atmospheric pressure, but to avoid contact with the light, open flame and high temperature, so it should be sealed and stored in some place where is cool and dry. In addition, MnO4W have some irritation, a person's skin and eye contact product will cause inflammation and other symptoms, so during the operation should to wear some protective gear. And it has a certain degree pollution of water, we can not let undiluted or large number products to reach ground water, water course or sewage system. What’s more without government permission do not allow this material release into the surrounding environment.

Manganese tungstate synthesis method:

1. Dichloride manganese and sodium tungstate cause metathesis reaction to obtain manganese tungstate precipitate and then after washing to dried at 1000 ℃.

2. Heat the calculated amount of MnCO3 and WO3 to produce yellow-brown manganese tungstate.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Lithium Tungstate

- Details

- Category: Tungsten Information

- Published on Tuesday, 28 July 2015 16:12

Lithium tungstate is a kind of BeSiO3 stone lattice which is colorless triangular crystal. its physical properties are shown below:the chemical formula: Li2O4W, molecular weight: 261.7196, density: 3.71g/ml, Solubility: soluble in water, but insoluble in ethanol. Its chemical properties are as follows: It can decompose in acid; On the other hand, heating it at temperature of 500 ~ 800 ℃, and then passed through H2 can restore to the tungsten bronze, and then heated to 600 ℃ generated WO2, the final product is W (β type) . Lithium tungstate is stable at room temperature and atmospheric pressure, but to avoid the light, open flame and heat, so it should be sealed and stored in where is cool and dry place. In addition, Li2O4W has acutely toxic, if human skin and eye contact it will cause inflammation and other symptoms, so when during at the operation should to take some protective gear. And Li2O4W has a certain degree pollution of water, the factories can not let undiluted or large number products to reach ground water, water course or sewage system, besides, without government permission do not allow material into the surrounding environment.

Lithium tungstate synthesis method: dissolution WO3 in Li (OH) or Li2CO3 solution to obtain Li2WO4.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Ore Processing Production line--Ball Mill

- Details

- Category: Tungsten Information

- Published on Tuesday, 28 July 2015 11:00

Tungsten Ore processing production line--ball mill Introduction:

Tungsten Ore processing production line --ball mill is the key equipment for secondary grinding after crushing. And it is suitable for grinding all kinds of ores and other materials, no matter wet grinding or dry grinding. Besides, it is mainly applied in many industries, such as ferrous&non-ferrous metal mine, building materials, chemical, electric power, coal, traffic, light industry, etc. In our company, this series of high-efficiency ball mill adopts rolling bearing support instead of sliding bearing support with bearing bush. Therefore, it can save energy by 10-20%. According to different discharging ways, it can be divided into two kinds, grate type and overflow type.

Structural characteristics of Tungsten Ore processing production line--ball mill:

Tungsten Ore processing production line --ball mill is made up of feeder part ,discharging part ,rotating part ,transmission part(reducer,samll transmission gear ,motor,electric control) etc. main part.Hollow shaft adopt steel casting, lining can be converted,big rotating gear processed by casting gear hobbing .In the barrel there are board of wear-resistant,have a good characteriatics of wear-resisting.The machine is of steady operating and reliable working.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Free Alkali Recovery From NaOH Leaching Liquor of Tungsten Ore by Electrolysis with Ion-Exchange Membrane

- Details

- Category: Tungsten Information

- Published on Tuesday, 28 July 2015 10:57

Caustic soda leaching liquor of tungsten ore always contains a certain amount of free alkali. General method of removing free alkali in the liquor is to neutralize it by inorganic acid. A new method, i.e. applying electrolysis with ion-exchange membrane to recover free alkali from caustic soda leaching liquor of tungsten ore, was proposed in the paper. In the electrolysis cell the effective area of membrane is 100 mm×100 mm, the anode is β PbO2 plated at screen of titanium net, the cathode is active nickel plated at screen of stainless steel net, and the membrane is a kind of perfluorsulphonic acid membrane. Some effect factors of electrolysis process including the NaOH concentration in anolyte and catholyte, distance between electrodes, temperature, current density, are investigated. The results show that, by choosing proper operating condition, the specific energy consumption can be controlled within 2 kWh•kg-1NaOH. Electrolysis with ion-exchange membrane can not only recover free alkali from caustic soda leaching liquor, reduce the consumption of inorganic acid, but also utilize the hydrogen gas produced in the process to produce tungsten powder.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Beneficiation Process of Tungsten Ore-II

- Details

- Category: Tungsten Information

- Published on Tuesday, 28 July 2015 10:25

Tungsten smelting and fire refining method are two kinds of water law. The use of wolframite concentrate or smelting scheelite concentrate, but different smelting process, so both wolframite deposits, there scheelite, we must each ore body, each calculated reserves. When the ore wolframite, scheelite coexists together, to elect a black tungsten concentrate and scheelite concentrate for smelting, respectively. The smelting of mineral raw materials as tungsten tungsten ore concentrates, containing WO3 should meet or greater than 65%. The pyrometallurgical into tungsten alloy (with W>70 or>65%) by Water Act, a positive tungsten smelting sodium, calcium APT or tungsten, etc. Finally, further processed into tungsten trioxide (containing WO3>=99.9%), then reducing agent (usually hydrogen) is reduced to tungsten powder (with W>=99.9%) and so on.

Tungsten is recovered from scheelite ore concentrates, or other tungsten concentrates which may, or may not contain scheelite in the form of sodium tungstate and in yields up to 99.5 percent or more by a process in which ground ore substantially below 200 mesh in particle size is first added to a 50 percent sodium hydroxide solution while being agitated to such an extent that the resulting mixture becomes a semi-solid as the temperature is raised above 80C. The semi-solid is then baked at 135 to 145C for about 1 to 2 hours, followed by adding sufficient water to the semi-solid to form a slurry having a sodium hydroxide concentration below 6 molar, separating the causticinsoluble sludge from the slurry and washing the sludge with a dilute sodium hydroxide solution to remove residual sodium tungstate.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Beneficiation Process of Tungsten Ore-I

- Details

- Category: Tungsten Information

- Published on Tuesday, 28 July 2015 10:06

Tungsten ore low must be integrated mineral-rich concentrate to a smelting raw material. According to the type of tungsten ore dressing it can be divided into wolframite and scheelite mineral beneficiation two types. Present mining to wolframite quartz vein type, accounting for the amount of ore taken out more than 90%. Tungsten ore dressing methods mainly include hand-selected, HM election, re-election, flotation, magnetic separation and electrostatic separation methods such as. Wolframite in order to re-election dominated by flotation mainly scheelite. Most of our wolframite is easy to choose the type of ore, while the composition of scheelite ore complex, and mostly of refractory ore, coupled with low grade, so not a lot of development.

In addition, tungsten oxide minerals such as tungsten China currently not recycled. China's tungsten ore dressing and processing plant started in 1952 a large-scale factory in Dajishan Tungsten establish 125t / d of gravity concentration plant, the late 50s, former Soviet Union Mechanobr Research and Design Institute for the downhill , West Mountain and hilly Miyama tungsten designed three large-scale tungsten ore processing plant put into operation one after another. 40 years in the production practice constantly sum up experience, and absorb foreign advanced technology dressing, through continuous improvement, so that beneficiation process is improving daily, processing technical and economic indicators have reached the world advanced level. Nanchang representative non-ferrous metals such as tungsten ore beneficiation company targets, despite nearly 10 years in the annual decline in ore grade, the tungsten recovery remained at 84% or more of the high concentrate grade (WO3) 66.7 % ~ 68.9% (up to 12 tungsten national standards: WO3 content is not less than 65%), ore grade (WO3) 0.25% ~ 0.27%, tailing grade (WO3) 0.036% ~ 0.046%.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Baseball Tungsten Dart Rule

- Details

- Category: Tungsten Information

- Published on Monday, 27 July 2015 18:35

Number of Players: Any number can play, but it is unusual to have only two players or two teams (like the game of baseball itself)

Numbers in Play: 1, 2, 3, 4, 5, 6 , 7, 8, 9

Rules of Play: This game is similar to the actual game of baseball. Players try to score as many points as possible per inning in order to win. The goal is to hit the number that corresponds to the current inning. For example, in the first inning players can only hit a 1 in order to score points. For any inning, a single is one run, a double is two runs, and a triple is three.

At the end of nine innings, the player with the most runs wins. If the players are tied at the end of nine innings, extra innings can be played with an equal number of turns per player (just like real baseball) until someone wins.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com