Tungsten Ore Application

- Details

- Category: Tungsten Information

- Published on Thursday, 30 July 2015 11:51

After by the beneficiation process of tungsten, tungsten was silver, high hardness, high melting point, room temperature, from air attack; can be used to manufacture filament and high-speed cutting steel, hard tooling, but also for optical instruments, chemical instrumentation. Tungsten because of its high temperature can maintain most of the high hardness and wear resistance is also used in the production of special steel. WC-based cemented carbide can be used for both cutting tools, mining machinees, and drawing modules. Contact material and the high proportion of alloy used in the manufacture of the gyroscope rotor, aircraft, control the rudder balance weight, radioactive isotopes and radiation shielding material basket, electric vacuum lighting materials. Tungsten ore and tungsten compounds are widely used in metallurgical materials tungsten raw materials.

Tungsten ore in particular extensive use of many and can produce and refine a variety of different products. For example, pure tungsten, tungsten alloy, tungsten heavy alloy, tungsten carbide, tungsten copper, tungsten powder, tungsten carbide powder, silicon carbide, tungsten electrode.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

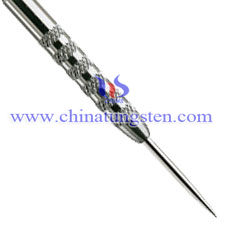

How to Know Which Type of Tungsten Dart Tip You Need?

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 July 2015 17:58

Steel tip darts are mostly used with bristle dartboards. Steel tip darts have a very sharp steel point to stick in the fiber of a bristle board. They can be complex with as many as five completely separate removable parts, and can be tuned for performance. Many models are available in different weights. Steel tip darts can be made of brass, nickel - silver, tungsten, and copper. However, most dart players will choose steel tip of tungsten, because tungsten is a metal with high-density and so durable. There are two options about steel tip of tungsten darts. One is fixed-point tip, the other is moveable-point tip. The fixed-point tip, as the name implies, it does not move, and this is the most common type. The moveable-point tip can move, it can help decrease the chance for a bounce-out. If you are always throwing on real hard boards, or older type boards that don't have all the nice features, moveable points may be for you.

Soft tip darts are mostly used with electronic dartboards. Soft tip darts have a flexible, plastic tip on the end to easily lodge into the holes on electronic dartboards. Usually lighter than steel tip darts, soft tip darts can be weighted differently, and be as complex. Soft tip darts can be made of plastic, brass, nickel - silver, tungsten, and copper. Most professional players would choose soft tip of tungsten darts.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Button Gradient Structure Optimization

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 July 2015 17:51

The top layer of gradient cemented carbide contains WC much to resist abrasion. The middle layer contains an amount of Co, so it has good toughness. This structure is beneficial for drilling, which has larger impact loads and longer working life. For instance, using φ45mm drill bit with DP55 cone button in limestone tunnel drilling, the average working life of gradient structure is 3121m at 1.96m/min compare with the ordinary 1000m at 1.48m/min. Many researchers overseas proves that the amount of carbon practical needs 0.1% -0.4% lower than theoretical value, and an appropriate increase in carburizing temperature conducive to migrate to the liquid Co sintered body inside. In addition, the different size of the sintered body should choose different respective carburizing time.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Button New Sintering Technology

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 July 2015 17:50

This new technology not only overcoming traditional vacuum sintering weakness that it will leave a amount of internal defects, which reduces tungsten carbide performance, but also decreases machinery expenses and improves the efficiency. It can remove the gap inside carbide button extremely, and picks out the raw grain to refine it. It is significant for improving the density of tungsten carbide button, and showing good performance. Currently, many manufactures are start using this sintering technology to provide a great quantity of tungsten carbide buttons.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Button for Drilling

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 July 2015 17:48

Drilling means that relevant tungsten carbide button should be tough and hard enough. According to the different types of rock formation and hardness, they can be divided into different grades, such as YG6, YG8, YG8C, YG11C, YG13C, YG15, etc. If the rock formation is pretty hard and the impact is huge, we should choose the carbides contain Co more and raw grains alloy. On the contrary, we should choose the little one.

Tungsten carbide button are bearing strength of pulling, bending, pressing, twisting and some cyclic stress when it is working. So they have to bear thousands and thousands of impacts and corrosion, which requires that the button on drilling bit distributes well-regulated in order to make bearing equally. When you use large-scale rock dill, the ball-shaped with double angle of chamfer is a better choice. On the contrary, cone and wedge is beneficial for prolong working life.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Choosing a Right Place to Hanging Dartboard

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 July 2015 17:48

When you want to play tungsten dart game, the proper place to hang a dartboard can be a difficult choice:

The area should be a low-traffic area to decrease the risk of injuries.

There should be nothing breakable 2-3 feet on either side of the board and preferably nowhere near the board at all. Darts can bounce 8 feet or more off the board.

An empty area roughly 5 feet wide and 11 feet long is essential. Although you can throw over items in the area, it can be very distracting. It is also annoying walking an obstacle course each time you pull your tungsten darts out of the board.

The floor should be considered in several ways:

1.A concrete, stone or tile floor will break tungsten darts and dull the points.

2.A wood floor will get lots of holes in it around the front of the board.

3.Linoleum or vinyl flooring will also get a lot of holes.Carpet will show A lot of wear from the traffic between the board and the line.

4.You will need to mark the throw line with tape, sticker, or a screwed down wood or metal bar.

5.Taking all this into consideration, you might want to think about purchasing a "dart mat". This is a roll out rubber mat that serves several functions. It protects the dart from breaking and dulling, it protects the floor and marks the proper distance to the throw line.

6.There should be adequate room for spectators and players when they are not throwing.

7.There needs to be a place for a score board in sight from the line, preferably right next to the board.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Bullet Button Shortcomings

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 July 2015 17:46

In terms of structure, the top of bullet type tungsten carbide button is short so that button will abrasive easily when it works. And the abrasion of button crown is becoming the main form of scrapping under such a situation, which impact and the hardness of rocks is not enough.when tungsten carbide button cutting rocks into a certain depth, the contact area between rock and buttons is growing faster. As a result, the pressure of carbide button decreases. This will lead a bigger plate growing faster than the crown abrasion. In addition, the taper is broken because of a lack of toughness and hardness, according to relevant statistics, there is 20% tungsten carbide drill bits were broken, which made of such bullet-shaped buttons at work.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How to Hanging Dartboard

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 July 2015 17:45

Dartboard needs to be hung exactly 5 foot 8 inches from the floor to the center of the bulls-eye. Good quality boards are hung from the center, making this measurement easy. If you have a board that hangs from the top, you will have to measure the distance from the center of the bulls-eye to the hanger and add that to the height. If a back board is used to protect the wall around the board, this will also have to be centered around the board.

Marking the throw line:

The throw line should be about 3 feet wide. It may be made of tape, a store bought throw-line sticker, a piece of wood or metal. It should be placed exactly 7 foot 9 and 1/4 inches from the face of the board for a standard steel-tipped setup. For soft-tipped darts, the line should be 8 feet from the face of the board. (Note: Some British pubs use an 8 foot or 8 foot 6 inch measurement for steel tip darts.) To measure from the face of the board, have someone hold a plumb line from the bottom-front of the board to the floor. If you don't have a plumb line, you can use a piece of string with a pencil or dart tied to one end. Make sure the throw line is exactly perpendicular to the face of the board and centered with the board. This can be accomplished by measuring from the bulls-eye to each corner of the line. If you have a carpeted area where you are going to setup your dartboard, you can use a strip of wood or metal with the "hook" side of a piece of Velcro attached to the back as your throw line. You can stick it to the carpet when in use and it won't move, then just rip it up when you're done.

Lighting:

Proper lighting of the dartboard is very critical. It is important to be able to tell exactly where the dart landed without moving from the throw-line. The ideal lighting is from 2 lamps mounted from the ceiling to the left and right of the board. Obviously, in a home this can be a little ugly and expensive. The main goal is to light it reasonably brightly and create as little shadow as possible.

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The History of Dartboard Numbering Scheme

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 July 2015 17:42

The pseudo-random arrangement of numbers was presumably invented in the 19th century by fairground people along with the very idea of a segmented board. There aren't any pictures of a fairground board prior to 1900 so one can only conjecture but there are two ways to look at the result. It is clear is that some effort has been taken to ensure that consecutive numbers are mostly placed well away from each other and that higher numbers aren't next to each other. Modern players playing in a pub would correctly feel that such a board requires less luck and more skill in order to hit the high numbers. And it would seem likely that a fairground owner would view things similarly - by not grouping the high numbers together it is much harder for a random unskilled punter to hit 3 high numbers in one turn and therefore a fairground stall owner could easily judge the winning threshold to make it tempting while making sure that not many prizes were won!

The oldest known picture of a dartboard is the apparently pre-1900 'Grimsby board' that features 28 semi-randomly situated numbers on a segmented board with doubles. This appears to relate to a game of skill rather than a fairground pastime.

The segmented numbering scheme that features on the London or Standard Board is inherited from the old Yorkshire, Burton, Irish and Lincoln boards which have a similar arrangement. Many people have written in to ask how this came about and, although there is no definite answer, here are some facts concerning 2 competing theories so that you can draw your own conclusions.

The most commonly espoused theory is that it was invented by a Brian Gamlin, a 44 year old carpenter from Bury, Lancashire in 1896. However, there is only one source for this story and Patrick Chaplin, who knows more about tungsten darts than anyone else, has hunted high and low for any evidence that Brian Gamlin ever existed and could find none. Arthur Taylor who knows more about pub games in general than anyone else is similarly cynical. Further, the first record of the numbering sequence anywhere is print is from 1916 and the idea that the board remained a rare thing for 20 years at that time, given that Gamlin apparently died in 1903 lacks credence.

Chaplin favours one Thomas William Buckle from Yorkshire as the most likely contender for the famous numbering scheme. A craftsman and domino maker, in 1913 he supposedly converted a London Fives Board into the first version of the standard Yorkshire board that we know today. His motive for doing this remains unknown but sometimes historians ask too many questions - maybe he was just tinkering around and thought it might make a good tungsten dart game!

Tungsten Dart Manufacturer & Supplier: Chinatungsten Online - http://www.chinadart.com/

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Points’ Corrosion

- Details

- Category: Tungsten Information

- Published on Wednesday, 29 July 2015 16:01

What influence the tungsten points’ rate are humidity, impurities and metal surfaces state in the air. If air humidity is greater, water film condensation on metal surface will be thicker too, therefore, water film resistance will be smaller and corrosion will faster.

The expression of tungsten points’ corrosion process

W + O2 = W - 4e + O2 = WO2

2WO2 + H2O – e = W2O5 + 2H

W2O5 + H2O - e = 2WO3 + 2H

WO3 + H2O = H2WO4(black gum)

H2WO4 – H2O = WO3(dehydration → tan dura)

The above expression shows that electrochemical corrosion’s nature is metal atom losing electrons and be oxidized process.

How to define electrochemical corrosion process is that metal is destroyed after an electrochemical reaction between electrolyte and metal.

The occurrence conditions of metal electrochemical corrosion:

1. There are potential differences

2. There are electrolytic liquid, etc.

In a humid environment, tungsten points will be corroded (especially when air humidity is higher than 60%), the process is called atmospheric corrosion, is also a species of electrochemical corrosion.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com