Tungsten Outlook 2017: Price on the Rise

- Details

- Category: Tungsten's News

- Published on Tuesday, 17 January 2017 16:07

- Written by Cristina

- Hits: 1086

The tungsten market started off with low prices at the beginning of 2016, a theme that seemed consistent throughout most of the year. Tungsten’s price has remained below $200 MTU, and it appears as though it’s been that way through to December.

A Made-in-China Triumph: China Develops Its Own Ballpoint Pen Tips

- Details

- Category: Tungsten's News

- Published on Wednesday, 11 January 2017 10:49

- Written by Cristina

- Hits: 669

Despite producing some of the world’s most spectacular infrastructure and sending astronauts into space, China has finally overcome a technological obstacle that has vexed Premier Li Keqiang: the ability to produce a decent ballpoint pen using domestically-made materials and components.

Li has long said that the fact China could not make the high-grade steel and precision machinery required to make the key component of the pens – the metal ball and its casing – reflected badly on Chinese manufacturing in general, state media reported.

Now, after five years of trial and error, Taiyuan Iron and Steel, one of the country’s biggest stainless steelmakers, has worked out the appropriate mix of alloys for high-performance stainless steel and to extrude it into a wire feedstock just 2.3mm thick.

Stationery manufacturers in China produce 38 billion ballpoint pens every year, but make less than 0.1 yuan on each pen, despite spending millions of dollars importing steel used to make the pen tips, at 120,000 yuan (US$17,000) per ton.

"The stainless steel used to make pen tips was all imported from Japan," said Xu Jundao, manager of Beifa Group, one of China's largest pen makers.

Though making a ballpoint pen may seem straightforward, producing a tiny tip with fluent writing effects requires over 20 processes. With machine precision down to the nearest micrometer, requirements for the quality of steel are high as it should be easy to cut but not liable to crack.

Tungsten carbide, as the high hardness material with well corrosion resist property, is an ideal material for ballpoint pen tips. It may have prosperous application in this field in the future with the improvement of manufacture technology.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

The Research Trends of Improving Tungsten Carbide Properties

- Details

- Category: Tungsten's News

- Published on Tuesday, 10 January 2017 14:12

- Written by tang

- Hits: 801

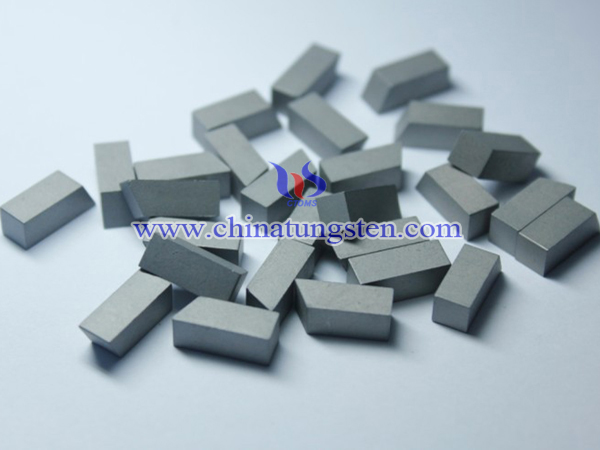

In the development processing, tungsten carbide encountered contradiction between strength and hardness, which is with high hardness but low strength, high strength but low hardness. WC particle size of tungsten carbide is always greater than its original particle size with traditional methods, and usually in a few microns.

However, many countries have encountered difficulties in the study of nano-carbide, the main problems are reflected in two aspects: First, the preparation of nano-WC-Co composite powder activity is very sensitive to temperature, in the high temperature will be immediately grown up. The current research and development trend is to improving the preparation of ultra-fine WC-Co composite powder method and improve the sintering processing. The compactness and uniformity of the tungsten carbide prepared by low pressure isostatic pressing sintering process are well, and the process has the advantages of short production cycle and small process loss.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

Processing of Fine-grained Tungsten Carbide is Immature

- Details

- Category: Tungsten's News

- Published on Tuesday, 10 January 2017 14:15

- Written by tang

- Hits: 803

In recent years, a variety of new tool materials endless, but tungsten carbide cutting tools will still be widely used in the future for a long period of time, it is necessary to study the development of new materials preparation technology to further improve and increase the tungsten carbide tool material’s cutting performance.

The strength and abrasion resistance of tungsten carbide cutting tools can be improved by refinement of hard phase grain size, increase of hard phase inter-granular surface area and enhancement of inter-granular bonding force. When the WC grain size reduced to sub-microns, the hardness, toughness, strength, wear resistance, etc. can be increased, and the required temperature can be fully densified. General tungsten carbide grain size is 3 - 5μm, fine-grained tungsten carbide grain size is 1--1.5μm (micron), ultra-fine tungsten carbide grain size can be up to 0.5μm (Micron, nanoscale).

As the grain refinement process is still not mature enough, so in the sintering process of tungsten carbide sintering is easy to grow into coarse grains, and grain growth will lead to the general strength of the material decreased, a single coarse WC grains are often Causing an important factor in material fracture.

| Tungsten Carbide Supplier: Chinatungsten Online tungsten-carbide.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News&Tungsten Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

PBOC Warns of Bitcoin Volatility

- Details

- Category: Tungsten's News

- Published on Monday, 09 January 2017 15:18

- Written by Cristina

- Hits: 736

China's financial services authorities required major executives of the Shanghai-based bitcoin trading platform BTCC on Friday to rectify misbehavior in the trading of the virtual currency - and to raise awareness of risks as the value of bitcoins experienced wild fluctuations.

sales@chinatungsten.com

sales@chinatungsten.com