[Know Tungsten] High Purity Blue Tungsten Oxide

- Details

- Category: Tungsten Audio

- Published on Wednesday, 28 February 2018 19:47

- Hits: 555

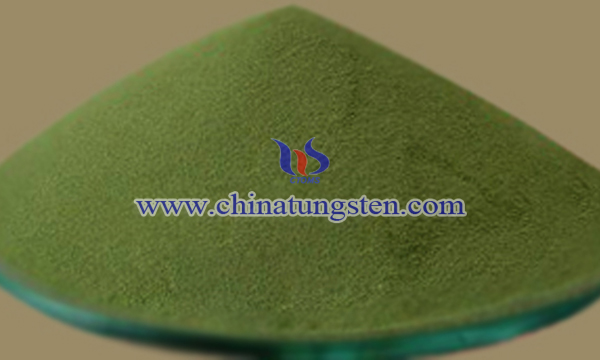

In theory, high purity blue tungsten oxide (BTO) refers to the β-tungsten oxide with a very high purity of 99.99% and above. The quality of tungsten products is getting more and more attention with the constant rise of high and new technology. According to the tungsten products on the performance of genetic, high-purity blue tungsten oxide will directly contribute to the high purity requirements of downstream products.

[Know Tungsten] Doped Yellow Tungsten Oxide

- Details

- Category: Tungsten Audio

- Published on Wednesday, 28 February 2018 19:09

- Hits: 548

Doped yellow tungsten oxide, also known as doped tungsten trioxide, is a good catalyst. Compared with the common yellow tungsten oxide, the photoelectric conversion efficiency and photoelectric catalytic activity of the doped tungsten trioxide have been improved. For example, Fe is doped to form Fe2O3 and Fe3+ can capture the photo electron, which inhibits the recombination of electron and hole.

[Know Tungsten] Tungsten Concentrate Electric Separation

- Details

- Category: Tungsten Audio

- Published on Wednesday, 28 February 2018 14:35

- Hits: 557

Electric separation utilizes different conductivity of mine and vein mineral grain, can process electric classification and separation in high voltage electric field. It is effective method to separate tungsten and tin in tungsten scheelite. But it is also used in tungsten concentrate gravity separation.

[Know Tungsten] Intermediates of Tungsten

- Details

- Category: Tungsten Audio

- Published on Wednesday, 28 February 2018 11:03

- Hits: 580

Intermediates of tungsten include ammonium paratungstate, tungsten metal powder, and tungsten carbide, cast carbide.

Ammonium Paratungstate

APT [(NH4)10[H2W12O42] • 4 H2O] is the main intermediate and also the main tungsten raw material traded in the market. APT is usually calcined to yellow (WO3) or blue oxide (WO3-X; a slightly substoichimetric trioxide with varying oxygen content).