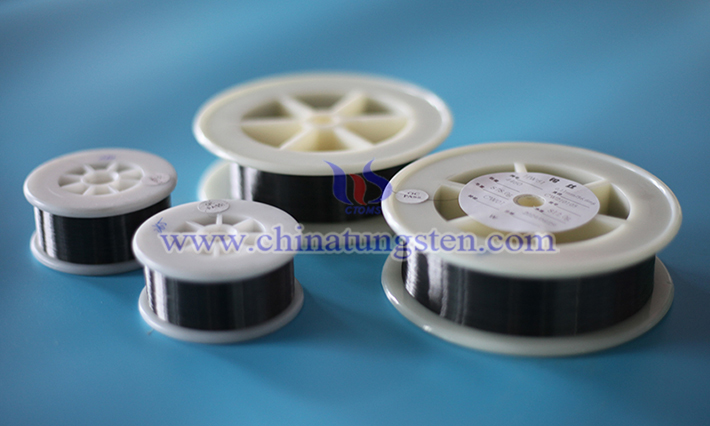

Cut-Resistant Tungsten Wire in Electronic Information Field

- Details

- Category: Tungsten Information

- Published on Monday, 17 March 2025 18:55

The application of cut-resistant tungsten wire in the field of electronic information is both extensive and significant, primarily due to tungsten's inherent properties such as high melting point, high density, excellent electrical and thermal conductivity, as well as superior mechanical strength and corrosion resistance. These characteristics enable tungsten wire to meet the demands of high precision and reliability in the electronic information industry, particularly in applications under extreme conditions. Below are the main applications of cut-resistant tungsten wire in this field:

1. Semiconductor Manufacturing

In the semiconductor industry, cut-resistant tungsten wire is commonly used in wafer dicing processes. Wafer cutting requires extremely high precision and wear resistance, and tungsten wire, with its high hardness and cutting durability, maintains stability during high-speed cutting, ensuring smooth and damage-free surfaces on silicon wafers or other semiconductor materials. This application is widely seen in the production of integrated circuits (ICs).

2. Vacuum Evaporation and Sputtering

Due to its high melting point (approximately 3422°C) and excellent thermal stability, tungsten wire is often used as an evaporation source in vacuum deposition equipment. By heating the tungsten wire, metals or other materials can be evaporated and deposited onto substrates to form thin films. This technique is widely applied in surface coating for electronic components, such as thin-film transistors (TFTs), display manufacturing, and optical coatings. Additionally, in the preparation of sputtering targets, tungsten wire is favored for its high purity and low diffusion rate.

3. Wires and Electrodes in Electronic Components

Cut-resistant tungsten wire, with its excellent conductivity and mechanical strength, is frequently used as fine wires or electrode materials in electronic components. For instance, in high-temperature electronic devices or vacuum tubes, tungsten wire can withstand extreme conditions while maintaining stable electrical performance.

4. Microelectronics Processing and Ion Implantation

In the field of microelectronics, tungsten wire is utilized in ion implantation equipment or microfabrication processes. Thanks to its cut resistance and high density, tungsten wire serves as a tool or auxiliary material, enabling high-precision processing for the production of micro-sensors, MEMS (Micro-Electro-Mechanical Systems), and similar applications.

5. Display Technology

In the manufacturing of liquid crystal displays (LCDs) or organic light-emitting diodes (OLEDs), tungsten wire is used in thin-film deposition or as a heating element due to its low thermal expansion and high conductivity, ensuring high quality and consistency in display panels.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com