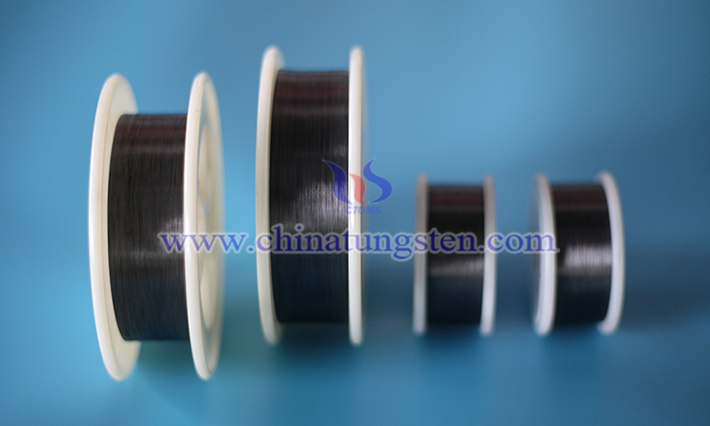

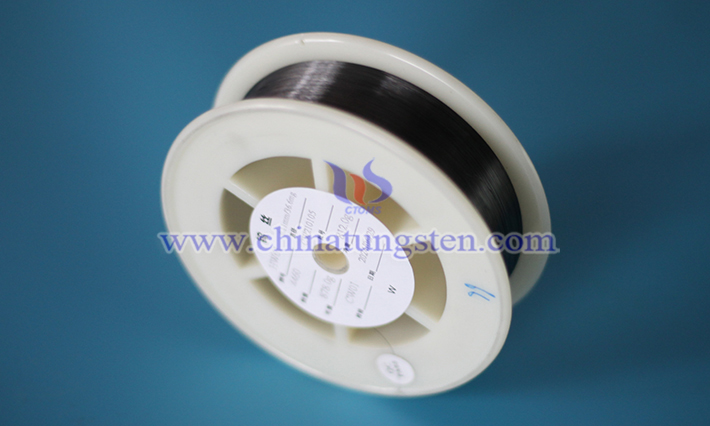

Applications of Cut-Resistant Tungsten Wire in the Textile Industry

- Details

- Category: Tungsten Information

- Published on Monday, 17 March 2025 19:00

Cut-resistant tungsten wire, with its high strength, wear resistance, and high-temperature tolerance, plays a significant role in specific scenarios within the textile industry. Below are the primary applications of cut-resistant tungsten wire in this field:

1. Protective Textile Manufacturing

Cut-resistant tungsten wire, either used alone or combined with high-performance fibers, significantly enhances the protective properties of textiles while improving user experience:

- Cut-Resistant Gloves: Gloves made with tungsten wire achieve a cutting resistance level at least two grades higher than traditional materials, with a 50% reduction in thickness, offering both flexibility and top-tier protection.

- Bulletproof Vests and Protective Clothing: When blended with high-performance fibers like aramid, tungsten wire improves puncture resistance, resulting in lighter garments suitable for special operations or extreme environments.

2. Smart Textile Development

With the rise of smart textiles, the conductivity and durability of cut-resistant tungsten wire make it a candidate for embedding into fabrics to create flexible circuits or sensors. For instance, in wearable devices, tungsten wire can serve as a conductive thread, integrated with textile fibers to enable signal transmission while maintaining structural durability.

3. Specialty Functional Textiles

- High-Temperature Filtration Materials: Fabrics blended with tungsten wire can withstand flue gases exceeding 1000°C, making them ideal for industrial dust removal systems or firefighting suits.

- Wear-Resistant Conveyor Belts: Incorporating a tungsten wire reinforcement layer extends the lifespan of conveyor belts by 3-5 times, suitable for harsh environments like mining.

- Industrial Sewing Threads: Ultra-fine tungsten wire threads can be used to sew high-temperature protective clothing, preventing the breakage issues common with traditional threads under heat.

4. High-Precision Textile Machinery Components

Due to its high hardness and wear resistance, cut-resistant tungsten wire is used in cutting tools or guiding components within textile machinery. For example, in high-speed looms or spinning equipment, tungsten wire withstands frequent friction and tension, ensuring precision and stability during fiber cutting or guiding, thus extending the lifespan of these components.

5. Specialty Fiber Cutting

In the production of high-performance fibers (e.g., carbon fiber or aramid) or composite materials, cut-resistant tungsten wire serves as an effective cutting tool. These fibers typically exhibit high strength and toughness, making them challenging for ordinary tools to cut, whereas tungsten wire, with its cut resistance and high-temperature tolerance, enables precise and efficient cutting.

6. High-Temperature Textile Processes

In textile processes involving high-temperature environments (e.g., manufacturing fireproof fabrics or insulation materials), tungsten wire can function as an auxiliary material or heating element. With its extremely high melting point (approximately 3422°C), tungsten wire remains stable under heat, facilitating fiber heating or shaping.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com