Application of Cut-Resistant Tungsten Wire in Optical Devices

- Details

- Category: Tungsten Information

- Published on Monday, 17 March 2025 19:03

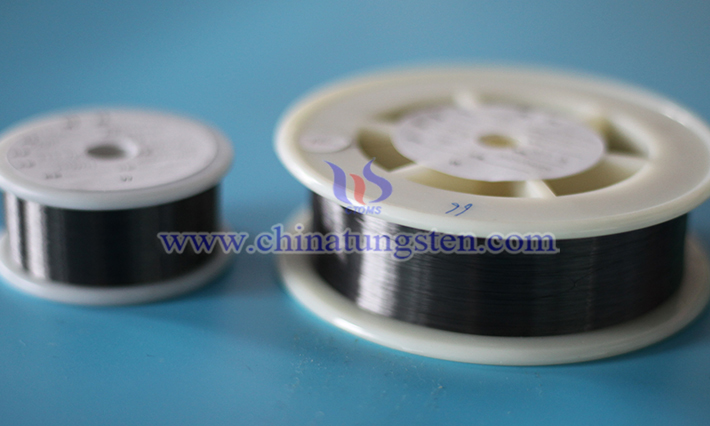

The high strength, hardness, melting point, and trend towards finer wire gauge of cut-resistant tungsten wire meet the requirements of the optical device field for precision, stability, and miniaturization development. Below are the main applications of cut-resistant tungsten wire in optical devices:

1. Electrode Wire for Electrical Discharge Machining (EDM)

Application scenarios: Precision cutting in mold manufacturing and aerospace parts processing.

Advantages: The high strength and temperature resistance of tungsten wire enable efficient cutting of hard materials (e.g., titanium alloys) and achieve complex shapes in optical device processing.

2. Wafer Cutting in Semiconductor Manufacturing

Application scenarios: Cutting precision components such as silicon wafers and brittle materials.

Advantages: The fineness and wear resistance of tungsten wire reduce cutting losses, improve processing precision, and ensure the integrity of microstructures in optical devices.

3. Medical Optical Instruments

Application scenarios: Cutting and shaping of minimally invasive instruments such as endoscopes and catheters.

Advantages: High biocompatibility and strength allow precise processing of tiny optical components (e.g., lenses, optical fibers), enhancing device durability.

4. Special Electronic Components and High-Temperature Wires

Application scenarios: Electronic components or wires in vacuum tubes and high-temperature furnaces.

Advantages: Temperature resistance and tensile strength ensure stable operation of optical devices in high-temperature environments.

5. Structural Support in Optical Instruments

Application scenarios: Brackets or connectors for instruments such as telescopes and microscopes.

Advantages: High stability and vibration resistance reduce the impact of external disturbances on optical performance.

6. Future Application Potential

As optical technology evolves towards higher precision and integration, the application scenarios of cut-resistant tungsten wire will further expand. Examples include:

Ultra-fine Optical Fibers: Utilizing the drawability of tungsten wire to develop micro-fine optical fibers for optical communication.

Optical Instruments for Extreme Environments: In harsh environments such as deep sea and high temperatures, tungsten wire as a structural support material can enhance instrument reliability.

3D Printed Optical Components: Combining additive manufacturing technology, tungsten wire can serve as a reinforcement phase in composite materials to print complex optical structures.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com