What Is Tungsten Alloy Collimator?

- Details

- Published on Monday, 11 August 2025 11:22

- Hits: 94

In a hospital imaging department, a patient lies on an examination table, about to undergo a CT scan. As the equipment activates, an invisible ray begins rotating around the patient’s body—this is the X-ray, capable of penetrating the body to clearly reveal internal structures, providing critical evidence for disease diagnosis. Behind these radiation applications, a key player operates quietly in the background: the tungsten alloy collimator. Though you may never have heard of it, it functions like a behind-the-scenes hero, influencing the effectiveness of radiation detection and treatment. Why is it entrusted with this responsibility, and what unique properties does it possess?

I. Advantages of Tungsten Alloy Collimators

A collimator is an optical instrument used to adjust the direction and shape of light, functioning to convert pergent light into parallel beams. It is widely applied in fields such as optics, lasers, fiber optic communications, and medical imaging. In radiation detection, it guides the direction of rays, ensuring they travel along specific paths to prevent scattering that could interfere with detection results. In medical imaging, such as common X-ray imaging, collimators control the shape and range of the ray beam. Among the materials used to manufacture collimators, tungsten alloy stands out as a top choice due to its unique advantages.

High Density: Tungsten alloy has a high density, typically reaching 18 g/cm³, which grants it strong radiation shielding capabilities. In radiotherapy equipment, it effectively blocks and absorbs excess rays, preventing radiation leakage that could harm surrounding personnel and the environment.

High Strength: The high strength of tungsten alloy is also notable. It resists deformation or damage under external impact or prolonged use. In industrial radiation detection equipment, devices may be subject to vibrations from the working environment or jolts during transportation. The high strength of tungsten alloy collimators ensures their shape and structural integrity, maintaining stable collimation performance, ensuring reliable and consistent detection results.

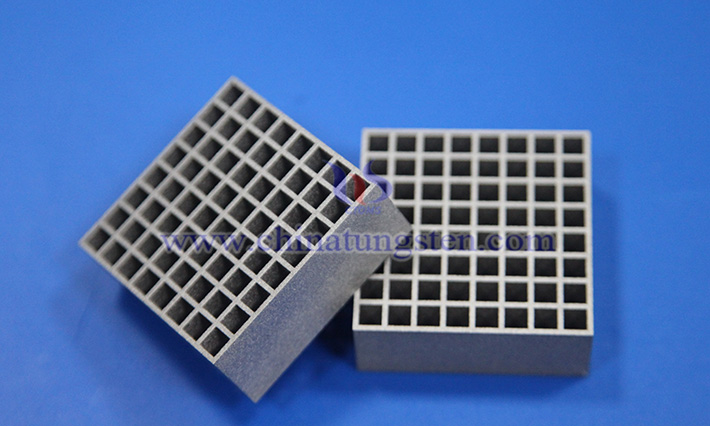

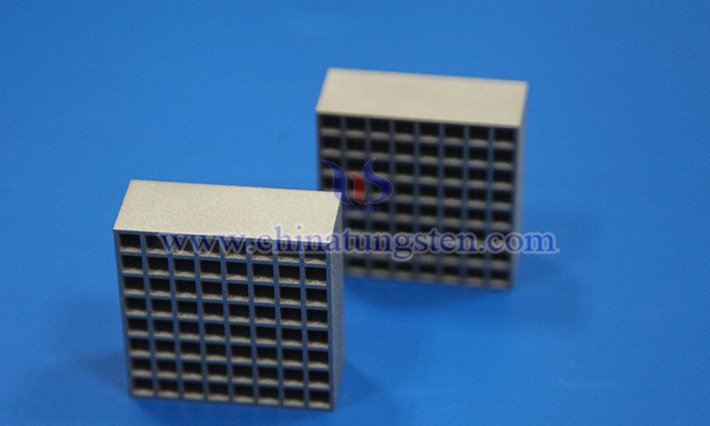

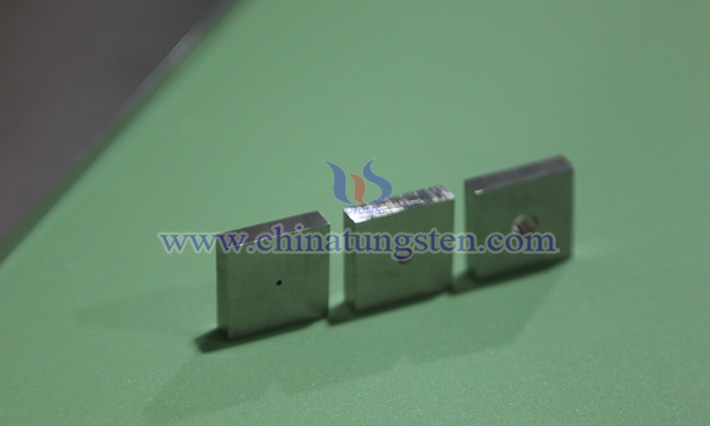

Good Machinability: Tungsten alloy can be processed into various complex shapes and high-precision dimensions through techniques such as forging and machining, meeting the perse requirements for collimator shape and accuracy in different radiation applications. In medical imaging equipment, to accommodate the detection needs of different body parts, collimators may need to be machined into special curved shapes or feature hole array structures. The excellent machinability of tungsten alloy enables these complex designs.

Environmental Characteristics: In an era where environmental awareness is deeply rooted, the eco-friendliness and recyclability of tungsten alloy are particularly important. Tungsten alloy is non-toxic, and its production, use, and disposal typically pose no harm to the environment or human health, with no radioactive substances generated. Additionally, its good recyclability allows it to be reused after processing, reducing resource consumption and waste emissions, aligning with modern green development needs.

Good Stability: With a high melting point, tungsten alloy remains solid and resistant to melting or deformation even in high-temperature scenarios like industrial radiation detection. Its low thermal expansion coefficient also prevents gaps or loosening due to temperature fluctuations, ensuring overall system stability.

Excellent Durability: In industrial environments with corrosive gases or liquids, or in medical equipment exposed to chemical reagents, tungsten alloy collimators resist corrosion. In radiation detection at chemical plants, where acidic or alkaline gases may be present, components made from ordinary materials are prone to corrosion damage, whereas tungsten alloy can withstand these corrosive factors, ensuring long-term stable operation.

II. Factors Influencing the Performance of Tungsten Alloy Collimators

1. Material Composition

In the microscopic world of materials science, the performance of tungsten alloy collimators is influenced by their material composition and microstructure. Besides tungsten as the primary component, other elements like nickel and copper play significant roles.

Nickel acts as a "fusion promoter" in tungsten alloys. It lowers the sintering temperature of tungsten, enabling densification at relatively lower temperatures, which saves energy and improves production efficiency. Nickel also prevents excessive grain growth during sintering, resulting in a more uniform and stable microstructure. Studies show that in some W-Ni-Fe tungsten alloys, an appropriate nickel content can enhance tensile strength and toughness, which is crucial for maintaining structural integrity under external impact or vibration.

Copper, on the other hand, has a unique role, improving the alloy’s thermal conductivity. During the operation of radiation detection equipment, significant heat is generated, and good thermal conductivity helps dissipate this heat, preventing performance degradation due to high temperatures. Copper also enhances the machinability of tungsten alloys, making it easier to process into complex shapes.

2. Microstructure

From a microstructural perspective, the microstructure of tungsten alloy is like a meticulously constructed "micro-architecture," where its rationality determines performance quality. Tungsten alloys typically feature a two-phase structure with tungsten particles uniformly distributed in a binder phase. When tungsten particles are fine and evenly distributed, the alloy’s strength and toughness improve. This is because smaller tungsten particles provide more grain boundaries, which hinder dislocation movement, thereby enhancing strength. Uniformly distributed particles also allow the alloy to bear loads more evenly under stress, avoiding localized stress concentrations that could lead to cracking or damage.

Research also indicates that the shape and orientation of tungsten particles affect collimator performance. When tungsten particles are spherical or near-spherical, the alloy exhibits better plasticity and toughness. However, when particle orientation follows a certain regularity, it may lead to variations in performance across different directions. In designing and manufacturing collimators, these microstructural factors must be considered comprehensively, optimizing process parameters such as powder particle size control, sintering temperature, and duration to achieve an ideal microstructure and enhance performance.

3. Manufacturing Process

Manufacturing processes like powder metallurgy and 3D printing significantly impact the performance of tungsten alloy collimators. Powder metallurgy involves mixing tungsten powder with other metal powders in specific proportions, pressing them into shape with a mold, and sintering at high temperatures to achieve densification. Its advantage lies in controlling material composition and microstructure, ensuring high product consistency. As an emerging technology, 3D printing enables layer-by-layer material deposition, overcoming traditional process limitations to create complex structures, special hole patterns, and internal channels. It also allows rapid production of prototypes or small batches, shortening research and production cycles.

4. Usage Environment

In practical applications, tungsten alloy collimators face the "challenges" of various complex usage environments, which significantly affect their performance. High-temperature environments pose a common challenge. When exposed to high temperatures, the material’s properties may change, potentially reducing hardness and strength. Radiation intensity also impacts performance. Prolonged exposure to high-intensity radiation may alter the microstructure of tungsten alloy, causing atomic displacement and lattice defects. These defects can accumulate over time, affecting the alloy’s mechanical properties and radiation shielding effectiveness.

- Chinatungsten Online: www.tungsten-alloy.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com