What Are the Uses of Tungsten Wire?

- Details

- Category: Tungsten Information

- Published on Monday, 11 August 2025 18:42

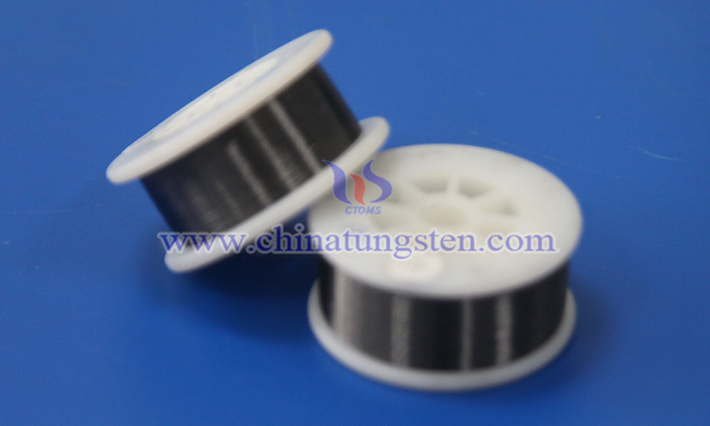

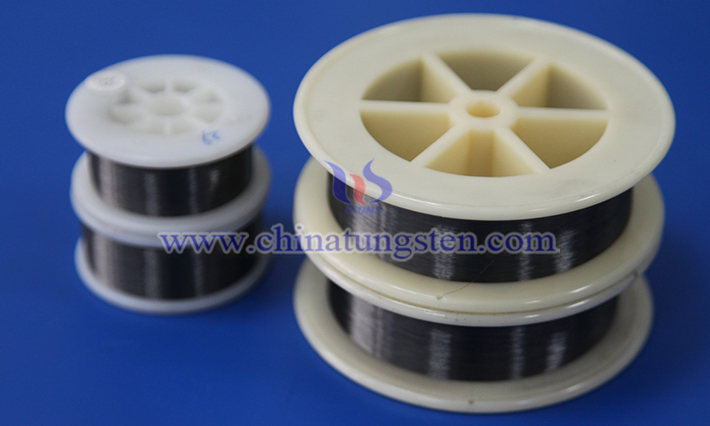

Tungsten wire has a wide range of uses. Its exceptional physical properties, such as its extremely high melting point (approximately 3422°C), excellent corrosion resistance, and good electrical conductivity, have led to its widespread application in industry, technology, and everyday life.

1. The Light-Emitting Element of Incandescent Light Bulbs

Tungsten wire is the core component of traditional incandescent light bulbs. Its high melting point and high-temperature resistance allow it to generate high temperatures and emit bright light when energized, without easily melting or breaking. Although the use of incandescent lamps has gradually declined with the popularity of LEDs, tungsten wire bulbs still have a place in certain specialty lighting applications, such as decorative lighting or vintage lamps, where their warm light effect is highly sought after.

2. Hot Cathode in Electron Tubes and Cathode Ray Tubes

Tungsten wire is used as the hot cathode material in electron tube and cathode ray tube (CRT) technology. When heated by electricity, the tungsten wire emits electrons, forming an electron stream used for signal amplification or image display. This property makes tungsten wire indispensable in older televisions, radar displays, and certain scientific instruments. Although modern display technology has shifted to liquid crystals and organic light-emitting diodes (OLEDs), tungsten wire still finds use in certain specialized equipment.

3. High-Temperature Electric Heating Elements

Due to its high-temperature and oxidation-resistant properties, tungsten wire is often used as a heating element in industrial high-temperature and vacuum furnaces. In these devices, tungsten wire can operate stably in extremely high-temperature environments and is used in processes such as metal smelting and ceramic sintering. Furthermore, in vacuum or inert gas environments, tungsten wire effectively resists oxidation, further extending its service life.

4. Welding Electrodes

Tungsten wire is used as a welding electrode in tungsten inert gas (TIG) welding. Its high melting point enables it to maintain stability in high-temperature arcs, making it suitable for welding high-precision materials such as stainless steel and aluminum alloys. The durability and electrical conductivity of tungsten electrodes ensure a stable and high-quality welding process, making them widely used in fields such as aerospace and automotive manufacturing.

5. Key Components in Medical Devices

Tungsten wire also has important medical applications, particularly in X-ray equipment. The cathode of an X-ray tube typically uses a tungsten wire. Heating the wire emits electrons, which then strike a target material to produce X-rays. This technology is widely used in medical diagnostic imaging, such as CT scans and X-ray examinations. The high stability and long life of the tungsten wire ensure reliable operation of the equipment.

6. Thin Film Deposition and Vacuum Evaporation

In semiconductor and optical manufacturing, tungsten wire is used in vacuum evaporation and sputtering processes. By heating the tungsten wire, the material is evaporated and deposited on the substrate, forming a precise thin film coating. These thin films are widely used in high-tech applications such as chip manufacturing, optical lenses, and solar cells. Tungsten wire's high-temperature stability and uniform heating ability make it an ideal choice.

7. Other Special Applications

Tungsten wire is also used in the manufacture of thermocouples for high-temperature measurement, as it maintains stable performance in extreme environments. Furthermore, tungsten wire serves as a key component in vacuum seals, scientific experimental equipment, and certain specialized industrial applications, where high precision and durability are required. For example, in particle accelerators or high-energy physics experiments, tungsten wire is used as an electron emission source or high-temperature support material.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com