【Know Tungsten】High-Performance Barium Tungsten Cathode: Applications and Features

- Details

- Published on Friday, 10 January 2025 14:59

- Hits: 336

The barium tungsten cathode is a high-performance thermionic cathode composed of a porous matrix filled uniformly with barium salts.

【Know Tungsten】Enhancing TIG Welding Performance with WL20 Lanthanum Tungsten Electrodes

- Details

- Published on Thursday, 12 December 2024 10:07

- Hits: 383

The WL20 lanthanum tungsten electrode is a tungsten-based alloy electrode material that contains approximately 2% lanthanum.

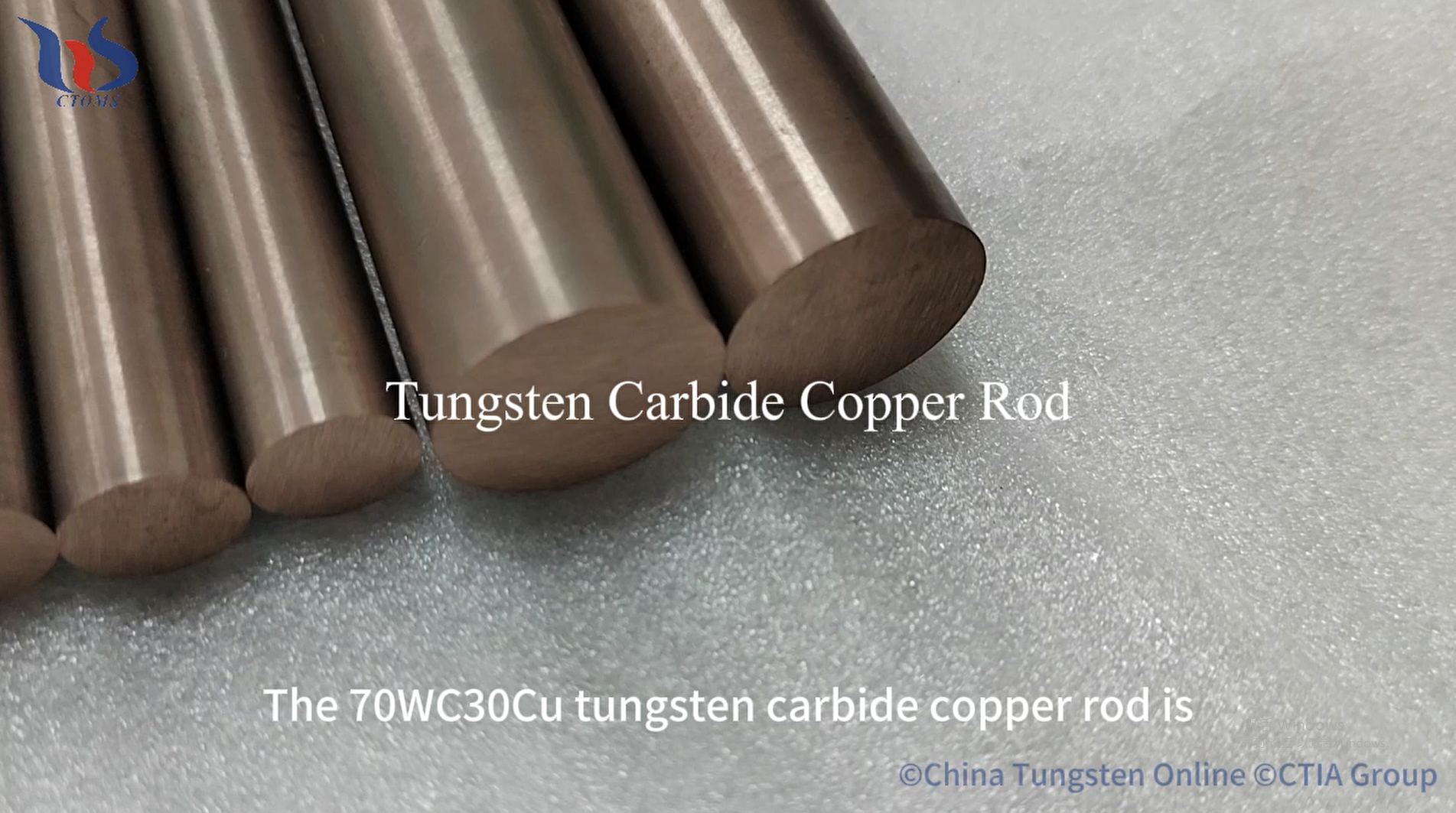

【Know Tungsten】Why Tungsten Carbide Copper Rod Is Ideal for Precision Instruments?

- Details

- Published on Thursday, 12 December 2024 10:04

- Hits: 361

The 70WC30Cu tungsten carbide copper rod is a composite material typically composed of 70% tungsten carbide and 30% copper. Due to the unique combination of tungsten carbide and copper, this material possesses exceptional physical and chemical properties.

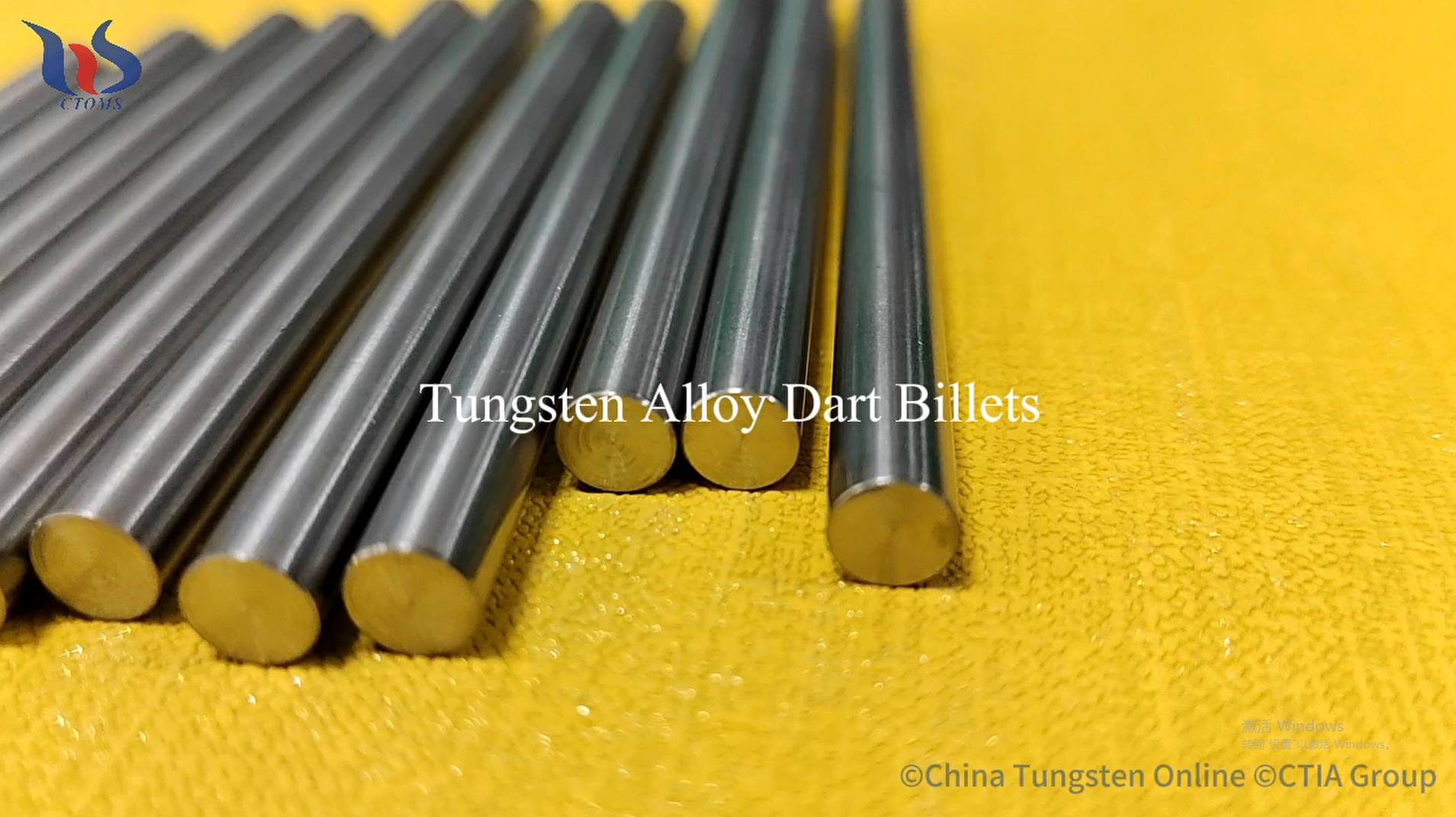

【Know Tungsten】Advantages of Tungsten Alloy Dart Billets: Precision and Durability

- Details

- Published on Thursday, 12 December 2024 09:59

- Hits: 384

Tungsten alloy dart billets are produced using a powder metallurgy process, combining materials such as tungsten, nickel, iron, and copper.

【Know Tungsten】What Are Advantages of Black Tungsten Wire?

- Details

- Published on Monday, 04 November 2024 11:39

- Hits: 453

Black tungsten wire is a fine wire made from tungsten material, known for its excellent electrical conductivity and high-temperature resistance. It is widely used in electronic components, filaments, vacuum devices, and high-temperature furnaces.

【Know Tungsten】What Is 0.8mm Mosquito-Type Tungsten Filament?

- Details

- Published on Monday, 04 November 2024 11:07

- Hits: 415

The 0.8mm mosquito-type tungsten filament is a specially designed filament, typically used in devices such as electron guns or displays.

【Know Tungsten】Features and Applications of Tungsten Retaining Rings

- Details

- Published on Thursday, 12 September 2024 09:27

- Hits: 513

A tungsten retaining ring is a precision-engineered component typically made from tungsten.

【Know Tungsten】Silver-Tungsten Rod: A High-Performance Composite for High-Temperature Environments

- Details

- Published on Thursday, 12 September 2024 09:23

- Hits: 446

Silver-tungsten rod is a composite material made from silver and tungsten, combining silver's high electrical conductivity with tungsten's high hardness and wear resistance.

【Know Tungsten】What Is Gold-plated Tungsten Wire?

- Details

- Published on Friday, 06 September 2024 09:48

- Hits: 471

Gold-plated tungsten wire is a material in which a 0.2-0.4 micron layer of 24K gold is plated onto the surface of tungsten wire,

【Know Tungsten】Tungsten Probe Is Used in Semiconductor Testing

- Details

- Published on Friday, 06 September 2024 09:45

- Hits: 452

A tungsten probe is a precision tool made from high-purity tungsten, widely used in semiconductor testing, electronic component inspection, and microscopic operations.

sales@chinatungsten.com

sales@chinatungsten.com