High Purity Tungsten Rod Introduction

- Details

- Category: Tungsten Information

- Published on Tuesday, 23 September 2014 15:17

- Written by jwy

- Hits: 588

High purity tungsten rod can be used as heat conductor, additive, crankshaft and cylinder barrel of automobile, parts of heat-resistant steel and electrode. High purity tungsten rods are mainly used in guns, rockets, satellites, airplanes and ships.

Chemical components for different purity Tungsten Rods:

| W (>%) | Chemical Content (<%) | |||||||||||

| 99.999 | Fe | Ca | Be | Sn | Al | Ni | Zn | Sb | Pt | K | Ta | Na |

| 0.1 | 0.05 | 0.005 | 0.005 | 0.05 | 0.01 | 0.05 | 0.05 | 0.03 | 0.005 | 0.1 | 0.05 | |

| Cr | Pb | As | Mg | Ti | Bi | Mo | Cd | Cu | Ba | Co | Mn | |

| 0.005 | 0.01 | 0.05 | 0.05 | 0.005 | 0.01 | 0.01 | 0.005 | 0.007 | 0.01 | 0.005 | 0.005 | |

| 99.99 | Fe | Ca | Be | Sn | Al | Ni | Zn | Sb | Pt | K | O | Na |

| 0.1 | 0.45 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.5 | 4 | 0.9 | |

| Cr | Pb | As | Mg | Ti | Bi | Mo | Cd | Cu | Ba | Co | Mn | |

| 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | |

| 99.95 | Fe | Ca | P | Sn | Al | Ni | N | Sb | Si | O | Pb | As |

| 5 | 3 | 1 | 0.1 | 2 | 3 | 3 | 1 | 3 | 3 | 0.1 | 2 | |

| Mg | C | Bi | Mo | |||||||||

| 2 | 5 | 0.1 | 1 | |||||||||

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

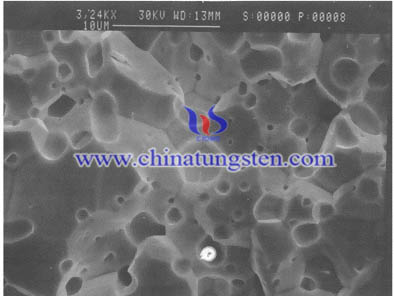

Grain Growth in Tungsten Rod

- Details

- Category: Tungsten Information

- Published on Tuesday, 23 September 2014 15:03

- Written by jwy

- Hits: 621

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

How to Place Fishing Sinkers to the Line 2

- Details

- Category: Tungsten Information

- Published on Tuesday, 23 September 2014 09:05

- Written by Sherry

- Hits: 572

Then wrap the line around the fishing sinker and tie a knot. Make the knot stable, so the fishing sinker does not slide up and down the line. Also, estimate where your hook will be and how much slack you need to retie it to the line. Your fishing sinkers should be close to the hook but does not need to be directly above it.

Then, create individual knots if you determined that you need to use more than one fishing sinker on your fishing line because you want to lower your bait. While it may be easier to simply slide a few sinkers on the line and tie a knot, it may break the line. Repeat the above steps for each individual fishing sinker you use.

Finally, replace the hook that you have removed from the line once you have placed the fishing sinkers securely on your fishing line.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Tungsten News & Tungsten Prices, WML Version: http://m.chinatungsten.com

Microstructure of Rolled and Annealed Tungsten Rod

- Details

- Category: Tungsten Information

- Published on Tuesday, 23 September 2014 14:53

- Written by jwy

- Hits: 588

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

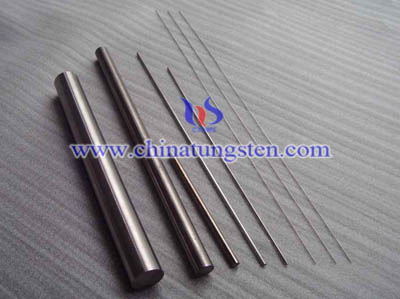

Tungsten Carbide Rod Applications

- Details

- Category: Tungsten Information

- Published on Monday, 22 September 2014 17:32

- Written by jwy

- Hits: 610

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com