M993 tungsten alloy penetrators

- Details

- Category: Tungsten Information

- Published on Wednesday, 18 June 2014 14:50

M993 tungsten alloy penetrators are American soldiers in 1992 to enhance the development of the plan, the purpose is to enhance the soldier for light armored vehicles strike capability. And 5.56mmM995 while research and development, both structures are different but the same size. In April 1997 shooting of BRDM-2 armored vehicles in Russia results showed that: the breakdown of these two bullets still valid after the armored vehicle anti-personnel side armor.

M993 tungsten alloy penetrators are American soldiers in 1992 to enhance the development of the plan, the purpose is to enhance the soldier for light armored vehicles strike capability. And 5. 56mmM995 while research and development, the two structures are different but the same size. In April 1997 shooting of BRDM-2 armored vehicles in Russia results showed that: the breakdown of these two bullets still valid after the armored vehicle anti-personnel side armor.

External M993 for mild steel jacketed, bullet inside a tungsten alloy penetrator. Time bomb by the Swedish Bofors CGAB production by the Dynamit Noble propellant production. The shells can be the same as the M240 machine guns, M60 machine gun, M24 sniper rifles and other weapons systems.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten alloy ball advantage in the military field

- Details

- Category: Tungsten Information

- Published on Wednesday, 18 June 2014 14:48

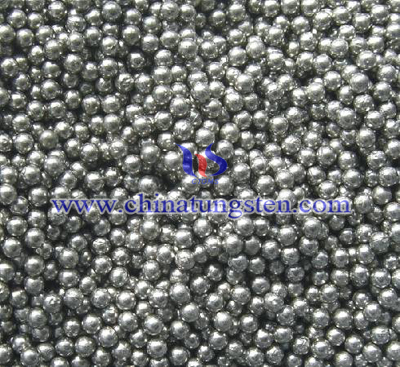

Tungsten alloy ball, small size, can be applied to missile projectiles, projectile, hunting equipment, shotguns, prefabricated pieces, missile weapons, armor-piercing ammunition counterweight; petroleum logging counterweight; There are some areas of precision instruments, such as mobile phones vibrator clock with weights, watches watches counterweight, phone vibrator, flywheel weight, tungsten ball. High proportion of tungsten and tungsten alloy ball counterweight counterweight and is widely used in factories, as well as in the military.

Military products above tungsten alloy lead substitute, since the higher density so that they can be better, even under extreme conditions, to maintain its shape. Although uranium to provide comparable density, the volatility and special licensing requirements needed for radioactive materials, the processing is difficult. Tungsten heavy alloy is a metallic green material, does not produce toxic substances in the use and production process. In the expanding military industry while also taking into account the environmental impact of the use of military weapons, environmental performance advantages of tungsten alloy makes it more and more prominent in the military field. Such as tungsten alloy tail off shell, tungsten alloy counterweight submarines, tungsten alloy engine parts and so on.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Rivet Bucking Bar Orientation 2

- Details

- Category: Tungsten Information

- Published on Wednesday, 18 June 2014 09:05

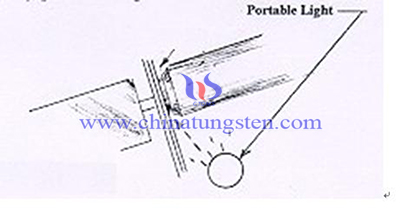

3. Push rivet back into place with gun set and reposition rivet bar, if necessary, to maintain its point of balance on the rivet. (repeat steps 2 and 3 until point of balance is determined). Often the index finger can be placed on the back of the rivet bar directly opposite the rivet tail. It then becomes the 'sensor' for correct bar position.

4. Pressure is held on gun while riveting. Tungsten alloy rivet bucking bar is held with only moderate force (otherwise rivet may be set with head proud of surface). A rubber grommet may be used over the rivet tail to assist in squeezing parts together during riveting. It acts as a 'pressure plate'.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.buckingbar.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Heavy alloy

- Details

- Category: Tungsten Information

- Published on Tuesday, 17 June 2014 16:08

Heavy alloy, also known as high density tungsten alloy, tungsten as matrix (content 85-99%), added alloy Ni, Cu, Co, Mo, Cr and other elements. Use according to the alloy composition and characteristics into W-Ni-Fe, W-Ni-Cu, W-Co, W-WC-Cu, W-Ag major series, a high density of 16 .5-19.0g/cm3, so also known as high-density alloy.

The main properties of an alloy of high specific gravity material are: high density, generally accounting for 16.5-18.75g/cm3; high strength, tensile strength of 700-1000Mpa; strong ability to absorb radiation, 30-40% higher than that of lead; thermal conductivity coefficient, W the thermal conductivity of the alloy tool steel 5 times; thermal expansion coefficient is small, only 1/2-1/3 of iron or steel; conductive properties, its good electrical properties and is widely used in lighting and welding industry; has good weldability and workability. Heavy alloy is mainly used in aerospace, aviation, military, oil drilling, electrical instrumentation, medical and other industries, can also be used to make a variety of anti-radiation shielding components. Currently heavy alloy belongs to the most important military-industrial applications.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten alloy penetrators core

- Details

- Category: Tungsten Information

- Published on Tuesday, 17 June 2014 16:06

Tungsten alloy penetrators core tungsten alloy penetrators penetrating kinetic energy is used to destroy armored targets. Tungsten alloy penetrators initial high speed, direct from the large, high-precision firing tank guns and anti-tank gun is the main bomb species. Guns, coastal artillery, anti-aircraft artillery and aviation authorities are equipped with the shells. Can be used to damage tanks, self-propelled artillery, armored vehicles, armored targets such as ships and aircraft, helicopters, cars, rockets, missile launchers transportation / launch vehicle, command vehicle, communication vehicle, radar and other non-armor weapons technology metal structure can also be used to destroy strong fortifications.

Why do penetrator bomb core tungsten alloy, because tungsten heavy alloy metal combined sequence, there is a high proportion of alloy is the most prominent feature is, we often say that the proportion of high density. Density tungsten alloy can reach 18g/cm3, steel gravity (7.8g/cm3) of 2.3 times. Sectional density tungsten alloy penetrators big heart, help to improve the ability to keep flying speed and penetration ability of steel, in order to improve the armor piercing kinetic energy to provide a possible fatal blow. Tungsten alloy heat; good thermal stability, the projectile during flight and air friction generates a lot of heat, if the piercing heat of filler is that it will not stick together, can not achieve piercing effect. This feature makes tungsten alloy penetrators good play its due effect.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Type of tungsten alloy swaging rod surface polished

- Details

- Category: Tungsten Information

- Published on Tuesday, 17 June 2014 16:04

Various tungsten alloy swaging rod surface finish:

First of all, including forging polishing and cleaning and polishing. Because in the process with some minor irregular surface oxide matte finish, so after forging polished gray. Cleaning polishing refers to the chemical composition of the surface clean.

Secondly, it is a machine developed by centerless polishing. Centerless polishing machine developed by ensuring close tolerances uniform size. Centerless polishing machine developed by providing a bright polished surface.

In addition, also by the polishing process. Polishing process is a typical form of processed parts of the surface. Must be specified in the special rough surface finish.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Rivet Bucking Bar Orientation 1

- Details

- Category: Tungsten Information

- Published on Tuesday, 17 June 2014 15:52

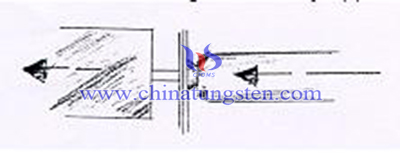

1.Rest tungsten alloy rivet bucking bar on inserted rivet and try to locate its point of balance.

2.With gun set in place, use rivet bucking bar to push rivet (and gun assembly) outward. Tungsten alloy rivet bar will then register at right angles to the rivet as it comes to rest on the aluminium.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online - http://www.buckingbar.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten alloy cube vibrator

- Details

- Category: Tungsten Information

- Published on Friday, 13 June 2014 14:36

Tungsten alloy cube vibrator commonly used in mobile phones, compared with other materials, tungsten alloy advantages of mobile phone vibrators are: small size, high density (17g/cm3), size and weight of high precision and non-magnetic. Tungsten alloy cube is an excellent material for this component.

Maximum density and high density tungsten alloy should be 18.6g/cm3. It is popular in weight, but those who need a high-capacity small components, such as: the phone vibrates and hour of vibration.

Shake the phone and the clock is one of our leading products. Compared with other materials, tungsten alloys with the vibrator accurate weight, and non-magnetic advantage. Especially because the weight of the vehicle will usually produce vibrations, and lighter phones may have weaker vibrating mechanisms.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten alloy counterweight cube

- Details

- Category: Tungsten Information

- Published on Friday, 13 June 2014 14:34

Tungsten alloy cube used more and more weight, such as: wheel weights, ballast weights F1 Formula One racing, racing counterweight balancing and so on. Tungsten alloy counterweight is the best material, and its use has also been well known, such as with a golf club, fishing rights in weight, such as military defense shotgun weight, prefabricated pieces, weapons and armor-piercing missiles. The overall balance of the golf club, it is important to achieve the best results in contact and more solid consistency and greater distance. A bat, there's a whole too heavy head bending machine makes a square position difficult to return to bat. In addition, it may encourage premature release players bat.

Tungsten alloy counterweight cube that can help solve the following circumstances: You can transfer the balance point of the bat close to the golfer's hands. You can think of it in the same way as a figure skater pulling their arms to their bodies, making them spin faster. Counter balance weight basically have the same length than the length of the bat. These weights are simply inserted into the butt end of the shaft mounted grip.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Military tungsten alloy cube

- Details

- Category: Tungsten Information

- Published on Friday, 13 June 2014 14:32

Military use tungsten alloy cube typically includes tungsten - nickel - iron or tungsten - copper - nickel-and even tungsten - nickel - copper - iron, add some of tungsten alloy, cobalt, molybdenum, chromium, etc., the most important performance tungsten alloy is small size and high density, which means that it can be applied very well in some areas. It is also used fishing gear counterweight counterweight military defense, as a counterweight shotguns, prefabricated pieces, missiles, weapons and armor-piercing shells and oil well logging. It is also used in some fields of precision instruments, such as mobile phone vibrators, clock cube, self-winding watch, anti-vibration and flywheel counterweight.

Cube tungsten alloy has excellent resistance to radiation, electric conductivity and high density (16-18.5g/cm3), good mechanical strength and corrosion resistance. It has expanded and increased elastic modulus coefficient functions. Tungsten alloy cube is widely used in military equipment, machinery, aircraft parts, medical shields and sports equipment.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com