Tungsten Carbide Cutting Tools For Machining

- Details

- Category: Tungsten Information

- Published on Thursday, 03 July 2014 18:17

Sintered tungsten carbide cutting tools are very abrasion resistant and can also withstand higher temperatures than standard high speed steel tools. Carbide cutting surfaces are often used for machining through materials such as carbon steel or stainless steel, as well as in situations where other tools would wear away, such as high-quantity production runs. Because carbide tools maintain a sharp cutting edge better than other tools, they generally produce a better finish on parts, and their temperature resistance allows faster machining. The material is usually called cemented carbide, hardmetal or tungsten-carbide cobalt: it is a metal matrix composite where tungsten carbide particles are the aggregate and metallic cobalt serves as the matrix. Manufacturers use tungsten carbide as the main material in some high-speed drill bits, as it can resist high temperatures and is extremely hard.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Application Of Tungsten Carbide In Industry

- Details

- Category: Tungsten Information

- Published on Thursday, 03 July 2014 18:14

Tungsten carbide tools have many applications based on the industries that use carbide equipment and other hard materials like diamonds. Tungsten carbide is especially used in sharpening of blades used in industrial applications. These tungsten carbide blades are used to improve versatility and productivity when sectioning plastic. During these cryo applications, the tungsten carbide blade is embedded in a holder made of steel. The blades are consistent and can survive through thousands of applications eliminating the need for frequent changes. The knives are also easy to handle and the risk of cuts is drastically reduced when compared to glass and razor or diamond blades. Its application is also seen in the making of nozzles in varying industry standards. Discharge units are easily manufactured using tungsten carbide. Small and large tiles can be formed into any sharp to fit customized surfaces or edges with minimal effort while still maintaining the high quality standards.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Application Of Tungsten Carbide In Sharpening Of Blades

- Details

- Category: Tungsten Information

- Published on Thursday, 03 July 2014 18:12

Tungsten carbide tools for cutting are used in machines that are intended to get into contact with carbon steel and stainless steel. Most of the time tungsten carbide is used as the first material to run through a surface, leaving a finer finish for other machines. In situations where high exposures to high temperatures are to be expected, tungsten carbide tool is employed since it can withstand extremely high temperatures that would melt industry strong steel or other metals. In such situations, the tungsten carbide is referred to as cemented carbide. During manufacture, cobalt is melted and once in the liquid stage, the cobalt combined with tungsten carbide alloys or particles, which act as the aggregate while the cobalt, forms the metal matrix composite. This process is called sintering or hot isostatic pressing. Addition of the naturally ductile cobalt metal goes a long way to ensuring that the tungsten carbide exhibits the characteristic brittle behavior. This process raises the durability and toughness f the final product. Machining of tungsten carbide tools is a difficult undertaking since the carbide tends to be brittle compared to other tool materials. As a result, it is prone to breaking and chipping. To counteract this problem, manufacturers have resorted to selling carbide inserts or simply carbide tools matching insert holders. With this configuration, the tungsten carbide insert is held firmly in place by the larger tool that is made of less brittle material. This combination is usually between tungsten carbide and steel. This arrangement has the benefit of incorporating carbide use without having to worry about the high cost of manufacturing the entire tool purely of tungsten carbide. Most modern face mills are using tungsten carbide inserts as well as some lather tools and end mills. To increase their lifespan, the tungsten carbide tools are coated with Tin, Tic or TiAIN. Most of these coatings have enabled the carbide tools to be harder and/or have more lubricity. Use of a coating also has the advantage of lowering the temperature associated with the cutting and it increases the life of the tool under use.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Physical Properties of Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Thursday, 03 July 2014 18:12

Tungsten power's physical properties. The relevant physical properties are average particle size, particle size distribution, apparent, tap, and compact or green density, specific surface other and can be influenced by the oxide properties and reduction conditions. They represent the important criteria for further processing and are responsible for the compactability, sintering behavior, dissolution reactions during liquid-phase sintering, and carburization reaction.

钨产品生产商、供应商:中钨在线科技有限公司

产品详情查阅:http://www.chinatungsten.com

订购电话:0592-5129696 传真:0592-5129797

电子邮件:sales@chinatungsten.com

钨钼文库:http://i.chinatungsten.com

钨新闻、价格手机网站,3G版:http://3g.chinatungsten.com

钼新闻、钼价格:http://news.molybdenum.com.cn

关注微信公众号“中钨在线”,了解每日最新钨钼价格

Tungsten Carbide Blades

- Details

- Category: Tungsten Information

- Published on Thursday, 03 July 2014 18:05

Tungsten Carbide blades are sharp and durable. They are wear-resistant, and can be used in a variety of industrial applications where extremely sharp cutting instruments are needed. For example, carbide blades are well suited to cutting reflective materials for plotting and sign making. Although prone to chipping and breakage, when these pitfalls are avoided with the proper engineering, tungsten carbide blades can sustain significant industrial stresses.

Tungsten carbide is less brittle than other metals, and thus can withstand the rigors of constant use easily.

In fact, switching from blades made of other materials, such as titanium, carbon steel, and aluminum, to tungsten carbide blades may actually increase productivity. By handling tough jobs with ease, carbide blades can increase productivity by 10 or 20 percent in some industries. Some factories have found that although tungsten carbide is often more expensive, its durability and ability to withstand pressure makes the extra cost worth it.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Agglomeration of Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Thursday, 03 July 2014 17:45

What is Agglomeration, with which is to change powder to compressed products. It is a traditional powder metallugy (PM) of tungsten powder.

The different between "as supplied" and "lab milled" (deagglomerated) particle sizes is measure of the degree of agglomeration. Agglomeration is very important for the strength of the green compacts and is therefore a necessary property for powder going into ductile tungsten production.

钨产品生产商、供应商:中钨在线科技有限公司

产品详情查阅:http://www.chinatungsten.com

订购电话:0592-5129696 传真:0592-5129797

电子邮件:sales@chinatungsten.com

钨钼文库:http://i.chinatungsten.com

钨新闻、价格手机网站,3G版:http://3g.chinatungsten.com

钼新闻、钼价格:http://news.molybdenum.com.cn

关注微信公众号“中钨在线”,了解每日最新钨钼价格

Specifications tungsten alloys with grenades

- Details

- Category: Tungsten Information

- Published on Thursday, 03 July 2014 14:16

Diameter: 53mm

Length: 104 mm

Weight: 130g

Throw Distance: 30 ~ 50 m

Features: Grenade safe to use, and will not cause environmental pollution.

Compared with lead, tungsten alloy grenade toxic pollution. So grenades replaced with tungsten alloy of lead, as grenades raw materials. Use grenades grenades tungsten alloy, will not cause harm to the environment. Tungsten line has 20 years of experience in the production grenade with a tungsten alloy. We can produce high quality tungsten alloy grenade to meet your needs.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Grenade tungsten alloy

- Details

- Category: Tungsten Information

- Published on Thursday, 03 July 2014 14:14

With the development of military industry, in recent years, grenades tungsten alloy as raw material, in the military field are becoming more common. Grenade tungsten alloy has many advantages: high-density, high melting point, corrosion resistance and so on. These advantages can be fully applied in the military field. Today, grenades tungsten alloy should be widely used in the military field, such as tungsten alloy bullets, tungsten alloy penetrators, tungsten alloy high-temperature components, and rocket grenades.

Grenades have three parts: filler, body and fuze.

Filling: filler based on usage, can be filled with explosive chemicals. Filler to be mixed with silica aerogels to enhance fragments scattering.

Body: the main body filler containing grenades and grenade fragments containing primer, flammable mixture, pyrotechnic delay column, combustible mixture. There main firing pin, firing pin spring, pull the safety pin safety pin and rings. Safety pin split ends at an angle.

Fuze: the role of the fuze is triggered filler, thereby detonating grenades.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Alloy Fishing Sinkers 1

- Details

- Category: Tungsten Information

- Published on Thursday, 03 July 2014 09:56

Tungsten alloy fishing sinkers are weights used to force a lure or bait to increase its sink rate , anchoring ability, and casting distance. Tungsten alloy fishing sinkers may be as small as 1/32 of an ounce for applications, even smaller for fly-fishing applications.

They can get as large as several pounds or considerably more for deep-sea fishing. They are formed into nearly innumerable shapes for diverse fishing applications.Unlike lead, environmental concerns do not surround the usage of tungsten alloy fishing weight materials.

A jig is a type of fishing lure that usually consist of a lead sinker with a hook molded into it and usually covered by a soft body to attract fish. However, recently, tungsten alloy fishing sinkers are becoming more and more popular among angles Tungsten alloy fishing sinkers with its high density, small volume, and environmental friendliness is quickly replacing lead weights.

Jigs are intended to create a jerky, vertical motion, as opposed to spinner baits that move through the water horizontally. The jig is very versatile and can be used in both salt water as well as fresh water. Many species are attracted to the lure that has made it popular amongst anglers for years.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

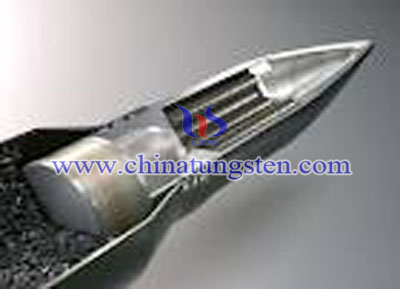

Tungsten Metal Slug

- Details

- Category: Tungsten Information

- Published on Wednesday, 02 July 2014 16:26

Slug tungsten alloy having a high density (60% higher than the density of lead, but also much higher than steel), high strength, high temperature properties. Based on these characteristics, tungsten alloy warhead widely used in the military field, as the bullet bullet, armor-piercing warheads, artillery shells and so on. Closely related to the warhead lethality and warhead flight speed. Bullet from World War I started, it has been used for killing enemy personnel, the warhead was used in carrying high explosives. Its functions and principles and high bursting disc is completely different.

Tungsten Metal Slug is mainly used for anti-enemy personnel. Tungsten Metal Slug contains one small tungsten alloy ball. But the bullet came close to the target, the warhead will release tungsten alloy pellets, these tungsten alloy pellets penetrate the human body, thus anti-personnel.

High density tungsten alloy pellets. Its high-density tungsten alloy means you can guarantee warhead muzzle velocity. The higher the speed, the greater the destruction, killing the better the performance. Tungsten Metal Slug is widely used in the military field.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com