Tungsten Carbide Cutting Tools Cutting Speed for Milling

- Details

- Category: Tungsten Information

- Published on Thursday, 11 June 2015 14:18

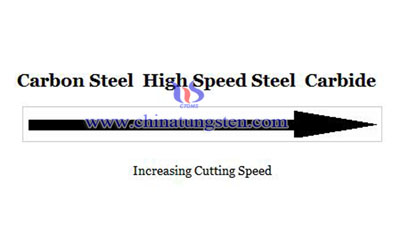

The cutting speed of the tungsten carbide cutting tool is the surface speed, which also refers to the speed at the milling cutters’ outside edge during its rotation. Specially ,the three directly related factors including, surface speed, surface footage, and surface area. The two wheels ones could be a proper example to explain, since one of its wheel is three feet in diameter and the other wheel which is one foot in diameter, roll each wheel one complete turn.

As the hardness of the cutting tool material makes a great effort to the suggested cutting speed, the tungsten carbide cutting tool has relatively harder cutting tool material, it presents faster cutting speed, whereas the softer the cutting tool material the slower the recommended cutting speed will be.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tool Wear Rate Relating to Synthetic Wood Products Cutting

- Details

- Category: Tungsten Information

- Published on Thursday, 11 June 2015 14:18

It is known that, during the synthetic wood products’(such as particle board) cutting processes, the factors like board density, resins and glues as well as silicon dioxide particles, which would affect tool wear, needed to take into consideration when adopting tungsten carbide cutting tool.

The function of silicon dioxide sand is normally referred to smooth the surfaces of the particleboard and since a large amount of the powder is usually ground against the wood surface, some of the particles may become embedded in the surface which subsequently may cause increasing the tungsten carbide cutting tools’ wear rates. The effect of silicon dioxide particles was investigated by Huber Wear, It is found that the wear rate increased linearly with increasing silica particle content. Tool wear was shown to be more closely related to the quartz content of wood than to the total salicaceous residue content.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Crucible for Sapphire Use(1)

- Details

- Category: Tungsten Information

- Published on Thursday, 11 June 2015 11:25

Sapphire tungsten crucible properties:

High density: ≥19.25 g / cm³;

High purity: ≥99.95%;

With exact dimensions;

Without internal rift within the crucible;

Application temperature range: 2000 ℃ -2400 ℃ around.

Sapphire tungsten crucible application:

It is used as a sapphire crystal growth furnace core container in sapphire growing.

Sapphire tungsten crucible - productive technology and equipment

|

Process |

Productive Technology |

Equipment |

Quality Check |

|

1 |

raw material-tungsten powder |

|

purity of tungsten powder |

|

2 |

sieving |

high frequency vibrating screen |

HB(brinell hardness), Fsss(furnace safety supervision system) |

|

3 |

mixing powder |

v shape mixer |

green strength |

|

4 |

isostatic pressing |

isostatic pressing machine |

rough-processed billet measurement |

|

5 |

rough billet lathing |

CNC(computer numerical control) vertical turning machine |

rough-processed billet surface quality |

|

6 |

if(intermediate frequency) sintering |

if induction sintering furnace |

finished product measurement |

|

7 |

competitive product lathing |

high-accuracy vertical turning machine |

quality of finished product |

|

8 |

packaging |

|

quality certificate |

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Control 0f Molding Pressure and Pool Pressure Mode of Tungsten Crucible

- Details

- Category: Tungsten Information

- Published on Thursday, 11 June 2015 11:15

Tungsten crucible’s molding is processing on the isostatic machine. When press the tungsten crucible, if the molding pressure is too large, it will make tungsten powder severely deformed, so the elastic stress will increase, eventually resulting in tungsten crucible cracking; if the molding pressure is too small, the density of the tungsten powder is not enough, tungsten crucible is also prone to cracking. Therefore, the scope of the molding pressure when pressing tungsten crucible should be at: 245MPa-260MPa.

In the pressing process, because the micro-hardness of tungsten powder is larger, so tungsten powder is easily deformed due to the external force, then, it will produce some distortion stress, if the pool pressure speed is too fast, then the release of the stress will be accelerated, which will result in crack of the tungsten crucible too. Therefore, only use the slow way of pool pressure mode to press tungsten crucibles.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Applications of Tungsten Poly

- Details

- Category: Tungsten Information

- Published on Wednesday, 10 June 2015 18:04

Tungsten poly or poly tungsten is a composition of various resins and tungsten powder. Tungsten poly is environmentally friendly. It is non-toxic and recyclable.

Due to tungsten alloy has excellent radiation attenuation properties, with thinner thickness but high effective in blocking harmful X-ray and gamma radiation, tungsten poly can be used in:

Radiation shielding and radiation-protective equipment;

X-ray inspection device for industrial and medical use;

ϒ-ray shielding material and substitute for lead fiber mat in nuclear reactor piping systems.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

What is Poly Tungsten

- Details

- Category: Tungsten Information

- Published on Wednesday, 10 June 2015 18:02

Poly tungsten or tungsten poly (also known as tungsten-filled polymer) is a composition of various resins and tungsten powder which are mixed together through special metallurgical technology. Poly tungsten is filled with tungsten particles up to 60% by volume and 96% by weight. Base resins in poly tungsten can include ABS (acryloynitrile butadiene styrene), PBT (polybutylene terephthalate), PU (polyurethane), PA (polyamide), PP (polypropylene), and TPE (thermoplastic elastomer).Poly tungsten is environmentally friendly. It is non-toxic and recyclable. Tungsten poly has high density, high radiation resistance, and high tensile strength. It is easily machined and malleable. Therefore, poly tungsten is the ideal material of radiation shielding instead of lead.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Copper Alloy Rod

- Details

- Category: Tungsten Information

- Published on Wednesday, 10 June 2015 17:54

Tungsten copper alloy rod is made of tungsten-copper composite material, tungsten-copper composite material is a two-phase structure fake tungsten alloy, composed mainly of copper, a metal matrix composite. Due to the physical properties of copper and tungsten are quite different, and therefore can not be produced using casting method, now commonly used powder alloy technology for production.

Tungsten has high melting point (tungsten melting point is 3410 ℃, iron melting point is 1534 ℃), high density (tungsten density of 19.34g / cm3, iron density 7.8g / cm3), copper has excellent thermal conductivity properties.However, tungsten copper alloy rod integrated advantages of tungsten and copper, have significant advantages. In addition, tungsten copper alloy rods (component is generally in the range of WCu7 ~ WCu50) uniform microstructure, high temperature, high strength, resistance to arc erosion, high density; moderate conductivity, thermal conductivity, high temperature materials are widely used in military, high-voltage switch with electrical alloy, EDM electrode, microelectronic materials, parts and components as widely used in aerospace, aviation, electronics, electricity, metallurgy, machinery, sports equipment and other industries.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Rock Drill Button Wear Resistance

- Details

- Category: Tungsten Information

- Published on Wednesday, 10 June 2015 17:20

Tungsten carbide is a material developed for highly demanding applications. The unique combination of hardness and toughness makes it especially suitable for wear resistant parts of tools for rock drilling.

Tungsten carbide rock drill buttons wear resistance has been the focus of numerous studies, and a large amount of wear data has been published. However, the broad range of possible wear mechanisms, the large number of rock types of very different character, and finally the large local property variations even within a single drill hole, has made it difficult to sort out a good general understanding. One conclusion stands out very clear: the wear data for one rock drill in one rock type is unique to that particular situation and should not be expected to apply to other rock drills in other rock types. Even so, some general wear mechanisms can be observed.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Rock Drill Button Wear Mechanism

- Details

- Category: Tungsten Information

- Published on Wednesday, 10 June 2015 17:19

Tungsten carbide rock drill buttons wear mechanisms have been the focus of numerous studies, and a large amount of wear data has been published. Recently a new, more comprehensive, view on the deterioration and wear mechanisms of cemented carbide rock drill buttons comes up. The new view combines some of most important aspects, including two life limiting factors, five classes of mechanisms of deterioration and five classes of material removal mechanisms. The view is based on careful high resolution investigations of worn tungsten carbide rock drill buttons selected from drilling of different rock types.

The deterioration includes a fundamental change of material and properties due to intermixing of rock material and cemented carbide in the surface layer of the button. It further includes corrosive decay and oxidation of WC and formation of large-scale cracks in a reptile skin pattern.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Crucible Sintering Process

- Details

- Category: Tungsten Information

- Published on Wednesday, 10 June 2015 17:18

Tungsten crucible sintering process:

Sintering in the medium frequency induction furnace, and the temperature is controlled at: 2200 ℃ -2250 ℃ around, and should be held 3h-5h. Thermal insulating once again in the middle-temperature phase, the control of temperature is around 1600 ℃ -1700 ℃, time thermal insulation is around 1.5h, so densification of product will be better . Moreover, heating temperature speed should not too fast, otherwise the crucible is easy to deform, and the temperature should be controlled at: 80℃-100℃around. Besides, the vacuum degree should be bigger than 0.67Pa when sintering.

In addition, through matting the same material tungsten plate at the bottom of the crucible or installing the furnace by proper way, and it will be possible to avoid the situation in which the sintering tungsten crucible bottom will crack, making the quality of tungsten crucible is guaranteed. By this sintering process, tungsten crucible density can reach to 17.3g / cm³ and above.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com