Tungsten Oxide Producing

- Details

- Category: Tungsten Information

- Published on Friday, 12 June 2015 15:53

Tungsten oxide is an important raw material for producing carbide. With the carbide industry development the quality and performance of the products have become more sophisticated. So to understand the performance of tungsten oxide for producing carbide with high performance has a significant advantage. Almost all tungsten oxides are based on APT (ammonium noon) as raw materials and calcined to produce. With different calcine conditions, the tungsten oxide powder is different. For example, using the same batch APT as raw material through different calcination process will produce violet tungsten oxide, blue tungsten oxide and yellow tungsten oxide. Each one has its own unique crystal structure, so they are not quite the same physical properties.

Violet tungsten oxide phase component is WO2.72 for its unique crystal structures so much use for producing fine tungsten oxide powder and fine tungsten carbide powder. Blue tungsten oxide phase component in theory is WO2.97. But in the actual blue tungsten oxide is typically a mixture of many tungsten oxides, including yellow or violet tungsten oxide phase. Yellow tungsten oxide has various crystal forms with different calcination temperature will obtain different WO3 crystal form. At a calcination temperature of 700 ℃ may producing orthorhombic tungsten trioxide.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Button Quality Control Methods

- Details

- Category: Tungsten Information

- Published on Friday, 12 June 2015 15:53

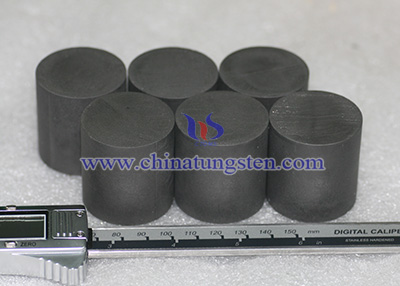

Tungsten carbide button quality control can be devided into inner quality control and external quality control. Inner quality control includes ingredient and construction. External quality control includes size and surface roughness.

1.Tungsten carbide button size, bending, burr, deformation should be within the standard.

2.Tungsten carbide button should be made under high temperature and long term carbonization. Carbon content should be between 6.14-6.20%. Tungsten carbide grain size is ought to be 2-3um.

3.Tungsten carbide carbon content should be within a certain limit. Magnetic saturation value of tungsten carbide button should be 93%-96%.

4.According to usage of tungsten carbide button, cobalt content should be 6%-16%. Wet grinding period should be within 24 hours. Sintering temperature should be high enough to increase tenacity of tungsten carbide button.

5.Reduce voids and large grain size inside of tungsten carbide button.

6.Use low pressure sintering, make the voids of tungsten carbide button smaller, enhance fracture toughness.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tool’s Tool Wear in Particle Board Machining (1)

- Details

- Category: Tungsten Information

- Published on Friday, 12 June 2015 15:32

It is known that, during the particle board cutting processes, as they can have abrasive fragments, loose micro-fragments can penetrate the tool under cutting pressure and preferentially remove the cobalt, which would affect tool wear.

When applying tungsten carbide cutting tool in particle board machining, a maximum wear tool area presents, which corresponded to the region in contact with the board surface whereas a wear minimum near the center of the cutting region. This profile is attributed to differences in board density and silicate content. It could be suggested that particleboard which can exhibit low tool wear in both the surface and middle layers can be manufactured depending on its structure and the composition of the materials used.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Cutting Tool’s Tool Wear in Particle Board Machining (2)

- Details

- Category: Tungsten Information

- Published on Friday, 12 June 2015 15:29

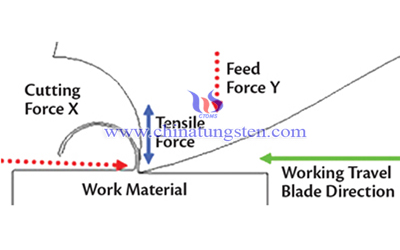

In terms of observing the tungsten carbide cutting tools’ cutting edges when machining three layered southern pine particleboard, the blunting was attributed to a combination of the effects of cured urea-formaldehyde resin and the higher board density. A similar effect of the resin glue content on wear was also shown in recently research, with the increasing of board density, silicates and resin content, a linear increasing relationship occurs in the abrasiveness of the board. In addition, if the resin content increases from 5 to 8%, there’s no effect on the tool wear while increasing the resin content from 9-11%, the abrasiveness almost doubled.

Most of the wear is found on the clearance face of tool, due to the rubbing action between the tool face and the wood. Less wear is found on the rake face, since no continuous chip is formed in machining synthetic wood products like particle board as they machine mostly by fracture.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Woodcutting Tool Cutting Forces (2)

- Details

- Category: Tungsten Information

- Published on Friday, 12 June 2015 15:29

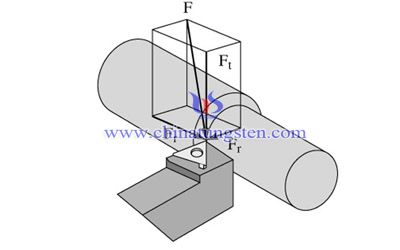

For the tungsten carbide woodcutting tool, the inclination of knife in its holder has an impact on the magnitude of the cutting forces applied as well.

The inclining the knife to the work piece advanced in input energy quantity control, which results in a lower transfer of stress from tool face to wood, hence causing smaller deformation zones in the contact zone. Some researchers measured the normal cutting force for a range of cemented carbides when cutting particleboard and found that the edge recession increased with increasing cutting force for the range of materials tested. The cutting forces measured were dependent on the binder content of the hard metal, with higher forces being recorded with increasing binder content.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Woodcutting Tool Cutting Forces (1)

- Details

- Category: Tungsten Information

- Published on Friday, 12 June 2015 15:25

The cutting forces involved in woodcutting by adopting tungsten carbide cutting tool consist generally of direct cutting forces, frictional forces, centrifugal forces associated with rotating cutter and forces due to attachment of the tool in the cutter head as well as forces due to machine vibration.

Since the rake, clearance and wedge angles of cutting tools refers to the display of material in the cutter, in addition it also indicates the volumes and lines of actions of the cutting forces, they would affect tool wear and several studies have been done which show this effect, with the wedge angle having the most effect. A rapid increase in the cutting force occurs during the initial stages of cutting after which the force tends to level off. Machine vibrations have been found to influence not only chip formation but also the friction forces and coefficients.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Properties and Features of Poly Tungsten

- Details

- Category: Tungsten Information

- Published on Thursday, 11 June 2015 18:46

The properties and features of poly tungsten:

High density: ≥11.34 g/cm3

Perfect radiation shielding performance: Tungsten has comparable radiation shielding ability as lead but is much healthier than lead. To date, many manufacturers, especially those in medical industry, are trying to replace lead radiation shielding products with Poly Tungsten products.

Good flexibility and excellent workability: Poly Tungsten sheets can be cut or holed with household scissors and formed into shapes with various curved surfaces.

Healthy and environmentally friendly: Poly Tungsten is made of non-toxic & recyclable materials and produces no pollution to the environment.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Polished Tungsten Tube

- Details

- Category: Tungsten Information

- Published on Thursday, 11 June 2015 18:05

Polished tungsten tube refers to semi-finished surface of pure tungsten tube after polishing products. Outer surface finish, wall caustic pure tungsten tube, the surface smooth, bright, shiny metal pan, the inner surface of the outer surface of the light is better. Pure tungsten tube diameter range is very wide, up to 100 mm, diameter size can also be controlled to 12 mm in length no restrictions, it can be customized according to user requirements. Usually taken pure tungsten tube through the use of pure tungsten rod system. Given its high temperature resistance, high melting point characteristics, pure tungsten tube can be used to protect its internal wire, the wire can also be introduced into the lumen to its high temperature gas or liquid.

Under standard conditions, unbound hard and rare metals, tungsten is a natural compound found on Earth. In 1781, a new element has been identified, first isolated in 1783 in the metal. Its important ores include wolframite and scheelite. Freedom notable feature is its excellent corrosion resistance, especially in the second highest of all the elements that most carbon it's all non-alloyed metal melting point later on. Equally striking is the high density of its 19.3 times that of water, comparable uranium and gold, much higher than the small amount of impurities of lead (approximately 1.7-fold), tungsten is often brittle and hard, making it difficult to work. However, very pure tungsten, though still difficult, more toughness, and can be cut with a hacksaw hard steel.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Radiation Shielding in Logging-While-Drilling

- Details

- Category: Tungsten Information

- Published on Thursday, 11 June 2015 18:05

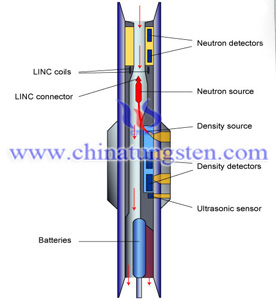

The logging-while-drilling tool provides real-time apparent neutron porosity, formation bulk density and photoelectric factor data to characterize formation porosity and lithology while drilling. Due to its high density, excellent absorption behaviour against radiation and environmental friendly characteristics, tungsten alloy can be widely used to produce tungsten radiation shield in density detector of logging-while-drilling.

The radioactive sources are safely contained in the drill collar and are connected to each other by a tungsten radiation shielding that allows fishing by wire line through the drill pipe.These nuclear measurements are borehole compensated for improved accuracy. 360-degree images of density and porosity result from the rotation of the tungsten density detector.

Tungsten Alloy Manufacturer & Supplier: Chinatungsten Online- http://www.tungsten-alloy.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Sputtering Gas Volume Influence Tungsten Oxide Nano Films

- Details

- Category: Tungsten Information

- Published on Thursday, 11 June 2015 18:03

Using reactive sputtering method producing tungsten trioxide nano films found the average particle size diameter is less than 100nm. The grains size of the tungsten trioxide (WO3) nano films are related to magnetic irradiation conditions and treatment temperature. After studied showed that sputtering gas volume and proportion play an important role at increase gas sensing property of nano WO3 film.

By XPS analysis, although proportions of mixed sputtering gas (O2 / Ar) is different, but the combination of W4f7 / 2 and Ols energy unchanged, namely 35.5eV and 530.6eV. And WO3 film stoichiometric not change, but when the O2 partial pressure is difference the WO3 nano-film microstructure will be a great change, this phenomenon can be explained by reduction aggregate. That is when O2 partial pressure increases the crystal grain size becomes smaller. However, if the O2 partial pressure is greater than 50% then it will result porosity reduced, thereby reducing the sensitivity of original, indicating that the optimum sputtering mixing ratio is 1: 1. So the sputtering mixed gas (O2 / Ar) ratio is 1: 1 which using DC reactive magnetron sputtering to produce WO3 nano film has best gas sensing properties.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com