Submicron Tungsten Carbide

- Details

- Category: Tungsten Information

- Published on Thursday, 07 August 2025 13:40

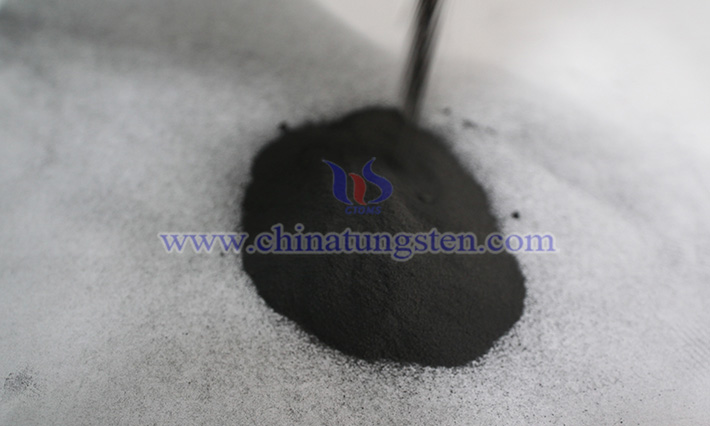

As one of the most important raw materials for producing hard alloys, the particle morphology, size, particle size distribution range, and impurity content of tungsten carbide (WC) powder directly impact the quality and application of hard alloys. Based on particle size differences, WC powder is categorized into ultra-coarse tungsten carbide, micron tungsten carbide, submicron tungsten carbide, sub-nanometer tungsten carbide, and nano tungsten carbide. So, what are the advantages and disadvantages of submicron WC particles compared to other sizes?

By definition, tungsten carbide is a compound composed of the transition metal tungsten and non-metal carbon, known in English as Tungsten Carbide, with the chemical formula WC and a molecular weight of 195.85.

From a physicochemical properties perspective, WC appears as a black granular powder with a melting point of approximately 2,870°C, a boiling point of about 6,000°C. It is insoluble in water, hydrochloric acid, and sulfuric acid but dissolves easily in a mixture of nitric acid and hydrofluoric acid. It exhibits hardness comparable to diamond, good electrical and thermal conductivity, a low thermal expansion coefficient, a high elastic modulus, and high compressive strength.

Notably, submicron WC powder has a particle size ranging between micron and sub-nanometer scales, from 100 nm to 1.0 μm. This allows it to avoid the agglomeration issues seen in sub-nanometer WC under certain conditions, offering better dispersibility, while requiring less ball milling time than micron WC, making it more suitable for producing submicron crystalline hard alloys. However, it is not ideal for 3D printing technology, as its larger particles result in relatively rougher products.

From a production process perspective, submicron WC powder is made from ammonium tungstate solution as the raw material, using a high-molecular surfactant as a dispersant and alcohol or ketone to enhance dispersion. It undergoes spray drying for rapid crystallization and drying to form fine, hollow, thin-walled spherical ammonium tungstate crystals, followed by pyrolysis, hydrogen reduction, and carbonization to produce it in situ.

In terms of applications, submicron tungsten carbide powder is primarily used to manufacture hard alloys, ultra-hard cutting tools, jet engine components, and kiln structure parts.

- Chinatungsten Online: www.chinatungsten.com

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com