Copper Tungsten Heat Sink Definition

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 July 2015 12:00

Tungsten copper heat sink is a composite of tungsten and copper. The coefficient of thermal expansion (CTE) of the composite can be designed by controlling the content of tungsten, matching that of the materials, such as Ceramics (Al2O3, BeO), Semiconductors (Si), Metals (Kovar), etc. The products are widely application in the fields such as radio frequency, microwave, high power diode packaging and optical communication system.

Tungsten copper heat sink is a heat base which is made of tungsten copper alloy. A heat base is a term for a component or assembly that transfers heat generated within a solid material to a fluid medium, such as air or a liquid. Examples of heat bases are the heat exchangers used in refrigeration and air conditioning systems and the radiator (also a heat exchanger) in a car. Heat bases also help to cool electronic and optoelectronic devices, such as higher-power lasers and light emitting diodes (LEDs).

Advantages: High thermal conductivity, Excellent hermetic, Excellent size control, surface finish and flatness, Semi-finished or finished (Ni/Au plated) products available properties of WCu and MoCu heat materials.

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Copper Tungsten Rod Definition

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 July 2015 11:48

Copper tungsten rod (WCu) is the composite of tungsten and copper which own excellent performance of tungsten and copper. It is used widely in such industries as engine, electric power, electron, metallurgy, spaceflight and aviation.

Tungsten copper rod is a kind of round rod. Tungsten copper rod is a kind of composite material, which is manufactured by high-purity tungsten powder and high conductivity copper powder with the production process of isostatic pressing, sintering temperature and copper infiltrated

The manufacturing process is as follows: press the refractory metal, sinter the pressed compact at a high temperature, and infiltrate it with copper. All this is done under very closely controlled conditions. The result is a relatively hard material with superior arc and wear resistance, high physical Properties: at elevated temperatures, and good electrical and thermal conductivity.

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Copper Tungsten Material Definition

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 July 2015 18:22

Copper tungsten alloy product is a sintered copper tungsten material manufactured by powder metallurgy. It forms dense composite offering hardness, wear resistance and a high softening temperature of tungsten combined with the good electrical conductivity of copper.

Copper tungsten alloy product is a pseudo-alloy of copper and tungsten. As copper and tungsten are not mutually soluble, the material is composed of distinct particles of one metal dispersed in a matrix of the other one. The microstructure is therefore rather a metal matrix composite instead of a true alloy.

The material combines the properties of both metals, resulting in a material that is heat-resistant, ablation-resistant, highly thermally and electrically conductive, and easy to machine.

Parts are made from the CuW alloy by pressing the tungsten particles into a desired shape, sintering the compacted part, then infiltrating with molten copper. Sheets, rods and bars of the alloy are available as well.

Commonly used copper tungsten alloy contains 10–50 wt.% of copper, the remaining portion being mostly tungsten. The typical properties of the alloy depend on its composition. The alloy with less wt.% of copper has higher density, higher hardness and higher resistivity. The typical density of CuW90 alloy, with 10% of copper, is 16.75 g/cm3 and 11.85 g/cm3 for CuW50 alloy. CuW90 has higher hardness and resistivity of 260 HB kgf/mm2 and 6.5 µΩ.cm than CuW50.

Copper tungsten may be used as an electrical contact material. In the most severe applications associated with power generation and transmission the switch may be totally immersed in oil. In these cases there is no advantage in using the tarnish resistant silver-based materials, as oxidation is prevented by the exclusion of air. Copper tungsten contacts are widely used in these cases, the selection of the grade used being dependent on the relative importance of conductivity and arc resistance.

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Causes of Tungsten Points’ Ablation of Car Distributor – IV

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 July 2015 17:49

The causes of tungsten points’ ablation of car distributor as seen below:

7. Soft spring of tungsten points’ arm of distributor. If the tungsten points’ arm spring is much too soft, when the car operating at low speeds, the flashover condition remain normal; due to the high speed inertia effect of the engine, tungsten points’ closure is more slower when the car is operating at a high speed, and the off-fire phenomenon will occur, therefore, the car's exhaust pipe will issue a irregular sound like "sudden, sudden, sudden". Besides, tungsten points will appear rebound phenomenon after closing, and the appearance of spark will be more vulnerable, ultimately tungsten points will be ablated.

8. The ground capacitor is bad. Due to the weak spark, the flashover distance is shorter when test fire, therefore, when the engine is operating at no load, it will be more normal. But the car is instable in operation process, the carburetor will appear tempering phenomenon, and when the engine is working at high speeds, the exhaust pipe will sometimes shoot. So the arcs of tungsten points will increase, and ablate tungsten points eventually.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

The Reasons of Tungsten Contacts Ablation of Car Distributor – IV

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 July 2015 17:46

The reasons of tungsten contacts ablation of car distributor as shown below:

7. The spring of tungsten contacts’ arm of distributor is too soft. If the tungsten contacts’ arm spring is too soft, flashover situation is still normal when the car running at low speeds; but when the car is working at a high speed, because of the high speed inertia effect of the engine, the closure of tungsten contacts is more slower, which appears off-fire phenomenon, so the car's exhaust pipe will issue a "sudden, sudden, sudden" irregular sound. Moreover, tungsten contacts after closure will appear rebound phenomenon, and the phenomenon make spark more vulnerable to emerge, and eventually tungsten contacts will be ablated.

8. Bad ground capacitor. When test fire, due to the spark is weak, and flashover distance is shorter, so the engine will be more normal when it is operating at no load. However, the car in working process is of instability, which would make carburetor appearing tempering phenomenon, and the exhaust pipe sometimes shooting when the engine is working at high speeds, make the arcs of tungsten contacts increase, eventually ablate tungsten contacts.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Spherical Crystal Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 July 2015 17:24

Spherical crystal ammonium paratungstate is an important raw material for preparing high density and high property tungsten alloy, tungsten oxide calcinated by spherical crystal ammonium paratungstate after hydrogen reduction has high apparent density, flow ability and even green density. It can be used to produce high property tungsten heavy alloy which has high density, tenacity and ductility. For example, W-Ni-Fe high density alloy produced by the spherical crystal tungsten powder which the fisher particle size is less than 200mm will has high density and tenacity.

The preparation of spherical crystal ammonium paratungstate is still under investigation. At present, the main technology for producing spherical tungsten powder is plasma condensation method. The equipment required for this method is complicated and the producing cost is very expensive. Producing efficiency is unsatisfied, thus it can not be used for industrial production which is only under experiment. The study on ammonium paratungstate is mainly focused on its particle size, particle size distribution, loose density and flow ability.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

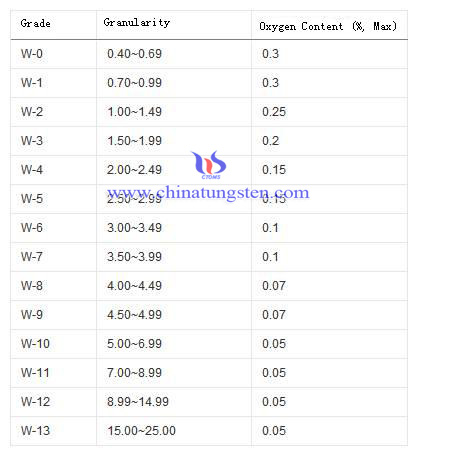

Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 July 2015 17:23

Tungsten powder is a powdered with polygon particle shape’s metal tungsten, its physical characteristics are as follows: chemical formula: W, molecular formula: 183.85, particle size: 2-0.5um, 4-6um, bulk ratio: 2.5-3.0g / cc. Tungsten powder CAS registry number is: 7440-33-7, which is raw materials of tungsten processed materials, tungsten alloys and tungsten products. Tungsten powder for oxygen and impurities content has certain requirements and commonly used tungsten powder particle size is 2-10um of average fsss size. In addition, in the tungsten powder’s specific surface, bulk density, tap density, etc. are also change at certain range. Tungsten powder classification is based on the purity and particle size. The figure is based on different size of tungsten powder, which is divided into 14 levels.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Spherical Crystal Ammonium Paratungstate Preparation Affecting Factors

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 July 2015 17:21

Below are the affecting factors of spherical crystal ammonium paratungstate preparation:

1.Under low speed of stirring, granulation rate of ammonium paratungstate is lower. When the stirring speed reaches to 80-90r/min, the granulation rate is ideal. With the increase of stirring speed, the granulation rate falls down.

2.With the increase of crystallization temperature, the granulation rate of ammonium paratungstate falls down. Consider of production cycle, crystallization should be under 85 degree Celsius.

3.With the postponed of time for adding liquid material, the granulation rate of ammonium paratungstate goes up. Consider of fisher particle size, loose density, flow ability and uniformity of particle, liquid material should be added under the solution density 16Be.

4.With the increase of liquid material amount, the granulation rate of ammonium paratungstate gose up. It reaches the maximum level when the adding amount is one time more than the original value. As the adding amount increasing, granulation rate falls down.

5.With the raising of adding speed, the granulation rate also goes up. Consider of fisher particle size, loose density, flow ability and uniformity of particle, liquid material should be added every three hours.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Micron-sized Ammonium Paratungstate

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 July 2015 17:20

Compared to traditional tungsten powder, preparation of fine tungsten powder can reduce sintering temperature. If the distribution of grain is close, structure of material after sintering will remain the nano-size.

A lot of researches have been done for super fine tungsten powder, like gas evaporation method, high energy ball milling; other method like control the hydrogen amount, temperature, adding dopant, etc. This method is easy to operate, low cost; the finished product is of high quality. Also yellow tungsten oxide, blue tungsten oxide, violet tungsten oxide is being used as raw materials to produce fine tungsten powder. Electrolyzation of tungsten oxide is also applied in the producing. But it is of high cost and low efficiency.

Ammonium paratungstate prepared by hydrogen reduction used to prepare tungsten powder is feasible. The ammonium paratungstate grain size is between 25-60um, which is not suitable for producing super fine tungsten powder. So the preparation of micron-sized ammonium paratungstate is the key problem.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ammonium Paratungstate Impurity Study

- Details

- Category: Tungsten Information

- Published on Tuesday, 07 July 2015 17:18

The spectrophotometric determination of impurities in the ammonium paratungstate is mainly determined by the reaction temperature, reaction time, NaOH concentration and stirring speed on the active ingredients wolframite tungsten leaching. Also investigate the properties of the resin in the ion exchange process, the exchange of the solution before concentration and flow rate, desorbent concentration, flow rate and temperature and other factors on the impurity removal rate during crystallization temperature.

Ammonium paratungstate is an important raw material which is used as a source for high-purity tungsten oxides, tungsten metal powders, carbides, or as a laboratory reagent. Also tungsten powder including tungsten trioxide, tungsten blue oxide. Those powders are then used to make numerous products including wire, cutting tools, billets, welding electrodes, mining tools and many others. There are alloy series too, such as tungsten carbide alloy blade, alloy drill, alloy molds, etc.; and other wear, pressure, temperature and other machinery and equipment components. Also used in the manufacture ammonium metatungstate and other tungsten compounds as additives for the petrochemical industry.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com