Silver Tungsten Contacts Produced by Infiltration Method

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 July 2015 16:26

The process of silver tungsten contacts produced by infiltration method:

Firstly, pressing the silver blank and tungsten skeleton without silver or porous skeleton with partial-induced silver; then, pre-sintering the porous skeleton at high temperature; after stacking up the two parts together, putting them in a special melt infiltration sintering furnace, and then liquid sintering, the sintering temperature is controlled above the melting point of silver. Silver under the molten state fills the pores of the porous skeleton by capillary action, forming silver tungsten contacts with high density eventually. The main process of silver tungsten contacts are as follows:

Tungsten powder + a small amount of silver, adding additional elements → mixing powder → pretreatment →skeleton molding + pure silver → pre-sintering (temperature > melting point of silver + 100 ℃) → infiltration → cold treatment

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Main Performance Index of Silver Tungsten Contacts

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 July 2015 16:24

Different tungsten contacts material have different characteristics, different proportions of the same tungsten contacts material also own different characteristics, their density, hardness, specific resistance have a different scope.

Main performance index of silver tungsten contacts (with different proportions) can be seen as follows:

|

Material name |

Specific resistanceμΩ·cm) |

Hardness(HB, MPa) |

Density(g/cm³) |

|

silver tungsten contacts(75) |

3.93-4.15 |

1629-1654 |

15.54-15.71 |

|

silver tungsten contacts(70) |

3.13-3.23 |

1681-1714 |

15.37-15.41 |

|

silver tungsten contacts(65) |

3.25-3.48 |

1535-1649 |

14.54-14.71 |

|

silver tungsten contacts(60) |

2.80-2.97 |

1419-1482 |

14.39-14.68 |

|

silver tungsten contacts(50) |

2.45-2.52 |

1145-1175 |

13.14-13.68 |

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

EPR of High-Spin Fe 3+ in Calcium Tungstate, CaWO 4

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 July 2015 16:18

The geff=30/7 isotropic signal in the EPR of high-spin Fe3+ compounds is discussed for both tetragonal rhombic crystal fields by reference to the resonance in calcium tungstate. The Fe3+/CaWO4 EPR signals are shown to arise from Fe3+ in two slightly different interstitial sites in the crystal; the crystal field in both sites is predominantly rhombic. Highly anisotropic signals arising from transitions within the other two Kramers' doublets were positively identified leading to an unambiguous calculation of the spin Hamiltonian parameters. The results are likely to be of great value in analysing similar Fe3+ spectra in crystals of biological importance.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Copper Electrode Classification

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 July 2015 15:53

Tungsten copper electrode can be classified into 3 types.

1. Tungsten copper (Class 10) is used for flash and butt welding electrodes in applications in which high heat resistance, higher electrical and thermal conductivity, high malleability, and low thermal expansion are required. This metal is created by combining 45% copper and 55% tungsten, resulting in a dense and hard metal with superior wear resistance and strength.

2. Tungsten copper (Class 11) contains 25% copper and 75% tungsten. Like Class 10, it has superior wear resistance and strength and good thermal and electrical conductivity. However, it is harder than Class 10 and used in applications that require moderate pressure.

Common uses include projection welding electrodes, flash and butt welding electrodes, light upsetting and seam welding bushings, and spot welding low conductivity steels. It is also widely used in chip carriers, substrates, flanges, and frames for power semiconductor devices.

3. Tungsten copper (Class 12) contains 20% copper and 80% tungsten, being stronger than Class 10 and 11 tungsten copper, it is commonly used in heavy duty projection welding electrodes, and cross wire welding. It is also used in the liners of some specialty shaped explosive charges for the defense and oil and gas industries.

Tungsten Copper Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-copper.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Site Occupation in Gadolinium-Doped Calcium Tungstate

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 July 2015 15:46

The electron spin resonance spectrum of the S-state ion Gd3+ in a calcium tungstate host lattice has been examined at 37.5 GHz over the temperature range 290 K to 4.2 K. Low concentration Czochralski-grown single crystals having gadolinium concentrations of about 100 ppm were used to ensure substitution by Gd3+ in calcium sites; the crystals were vacancy compensated. Although the general features of the 290 K spectrum agreed well with that reported previously by Hempstead and Bowers, extra lines were observed very close to the main ΔM=1 transitions. Examination in theφ-plane showed that the extra lines were most pronounced nearφ=55° and that their intensites relative to those of the main transitions increased as the temperature was reduced. The extra lines are explained in terms of the ordering of oxygen vacancies.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Paramagnetic Resonance Study of Irradiated Single Crystals of Calcium Tungstate

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 July 2015 15:34

Gamma irradiation of calcium tungstate at 77°K produces two paramagnetic species in high yield. Measurements of yields and of rates of disappearance upon warming indicate the two species are formed and disappear upon warming in one to one correspondence. The principal axis directions and gtensors have been measured and indicate that one species contains a surplus electron while the other is electron‐deficient (hole). Hyperfine effects of W183 have been observed. The electron‐deficient species contains two tungsten atoms with small isotropic hyperfineinteractions. Its unpaired electron must be highly localized in orbitals of atoms other than tungsten. The electron‐surplus species contains one tungsten atom with an anisotropichyperfineinteraction. This center could be WO4 3-, but from the lack of symmetry of the measured g values it must be formed near a lattice defect. Experiments with heat‐treated crystals indicate lattice defects to be important in the radiation effect.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ground‐Term Energy Levels of Triply Ionized Holmium in Calcium Tungstate

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 July 2015 15:11

The energy levels of the 5I ground term of Ho3+ in single crystals of CaWO4 were established by absorption and fluorescence spectra measurements. The measurements were made using crystals at temperatures near 2, 20, and 85°K. Most of the observed transitions can be accounted for by the electric dipole selection rules. Magnetic dipole selection rules cannot be ruled out for some of the lower energy transitions, however. Calculations were made to determine the effects of the crystalline host material on the Ho3+ energy levels. An effective Hamiltonian of the form suggested by Karayianis was diagonalized in a basis of Russell–Saunders wavefunctions to obtain the calculated energy levels and wavefunctions for Ho3+. Such a calculation takes into account the complete J mixing of the states within the ground term and is equivalent to determining the effects of the spin–orbit interaction to better than second order. In the calculation, an rms deviation of 10 cm−1 was found as the best agreement between the theoretical and experimental energy levels using the Hamiltonian, H = λ1(L⋅S) + λ2(L⋅S)2 + λ3(L⋅S)3 + ΣlmB+lmClm. The empirically determined parameters yielding this rms deviation are (in cm−1): λ1 = − 487.9, λ2 = − 6.601, λ3 = − 0.1801, B20 = 436, B40 = − 664, B44 = 779, B60 = − 33,ReB64 = 558, and ImB64 = 196. The g‖ factor for the ground state of Ho3+ in CaWO4 was calculated to be 13.675. This is in agreement to within 0.12% of the experimental value of 13.691 ± 0.006 reported by Kirton.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

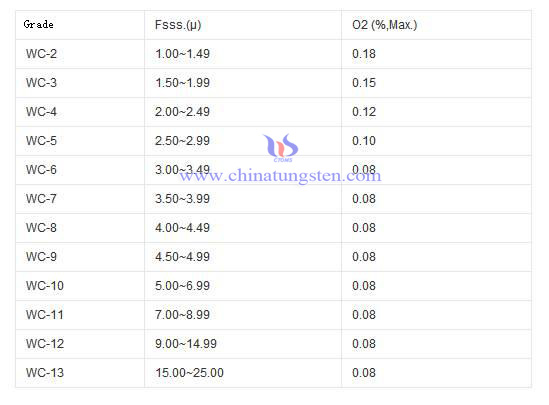

Tungsten Carbide Powder (2)

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 July 2015 14:51

Tungsten carbide powder (WC) is kind of dark gray powder, which using proportional tungsten powder and carbon black mixture as raw material to produce tungsten carbide powder. And in tungsten carbide powder the carbon atoms embedded tungsten metal lattice gap and did not destroy the original metal lattice, but to form interstitial solid solution, also known as interstitial compound. It is mainly used in produce tungsten carbide alloy.

The production of tungsten carbide powder is mainly through mix metal tungsten powder and carbon black as raw materials which according to a certain proportion of formulated. And then putting mixture into the graphite boat and placed in the carbon tube furnace or a sense of high-frequency electric furnace with a certain temperature to carbonization, and then by ball milling, screening to obtain tungsten carbide powder.

Tungsten carbide powder should be stored in dry, ventilation and acid-free atmosphere, to prevent oxidation, in which the storage period should not exceed six months. The external package of tungsten carbide should be drum and the internal packaging should be polyethylene bags, tightly sealed. According to fsss's size, tungsten carbide powder can be divided into 12 grades, as shown below.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Powder (1)

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 July 2015 14:48

Tungsten carbide powder (WC) as a black hexagonal crystal with a metallic luster, a dark gray powder, the hardness close to diamond, is the main raw material for the produce tungsten carbide. Its physical characteristics are as follows: chemical formula: WC, melting point: 2870 ℃, boiling point: 6000 ℃, the relative density of 15.63 (18 ℃), it does not dissolve in water, hydrochloric acid and sulfuric acid, easily dissolved in mixture acid of nitric acid and hydrofluoric acid which is a good conductor of electricity and heat. Tungsten carbide is fragile, if adding a small amount of infiltration of titanium such as cobalt, titanium and other metals can reduce brittleness, but also make the tungsten carbide used in more areas. Using tungsten carbide as steel cutting tools used often adding titanium carbide, tantalum or they mixtures in order to improve the anti-knock capacity.

Tungsten carbide powder may be dissolved in a variety of carbide, especially in titanium carbide forming solid solution TIC-WV. Another compound of tungsten and carbon is tungsten dioxide carbide, the formula W2C, a melting point of 2860 ℃, boiling point of 6000 ℃, the relative density of 17.15, while its properties, preparation method, use of tungsten carbide powder and similar.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Hexafluoride’s Application

- Details

- Category: Tungsten Information

- Published on Wednesday, 08 July 2015 14:46

Tungsten hexafluoride (WF6) is only stable varieties in tungsten fluoride which can produce by industrial. It is mainly used in the chemical vapor deposition of tungsten, the chemical equation for this reaction is: WF6 + 3H2 → W + 6HF. The reduction of tungsten hexafluoride can be restore to metallic tungsten and HF by hydrogen or other reducing gas (such as GeH4, SiH2F2 and diethylsilane etc.) at high temperatures. Tungsten hexafluoride as a raw material widely used in the electronics industry as base of tungsten metal chemical vapor deposition (CVD) process technology, such as using WSi2 as wiring materials of LSI which is made by WF6. Besides, using CVD technology of mixing metal to produce tungsten and the rhenium complex coating may be used to manufacture X-rays emitter electrode of a solar absorber. What’s more WF6 in the electronics industry still mainly used as a semiconductor electrode and the conductive paste and other raw materials.

In addition to applications in the electronics industry, tungsten hexafluoride used in non-electronic aspect is also very broad. By CVD technology to generate hard tungsten carbide on the surface of the steel can improve the surface properties of the steel. Additionally, tungsten hexafluoride is also widely used in fluorinating agent, polymerization catalyst and feedstock of optical materials to manufacture low resistance and high melting point interconnect lines or some components, such as tungsten tube and crucibles.

Tungsten Manufacturer & Supplier: Chinatungsten Online -http://www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com