Modified Tungsten Materials Inhibit Recrystallization

- Details

- Category: Tungsten's News

- Published on Monday, 29 May 2023 19:09

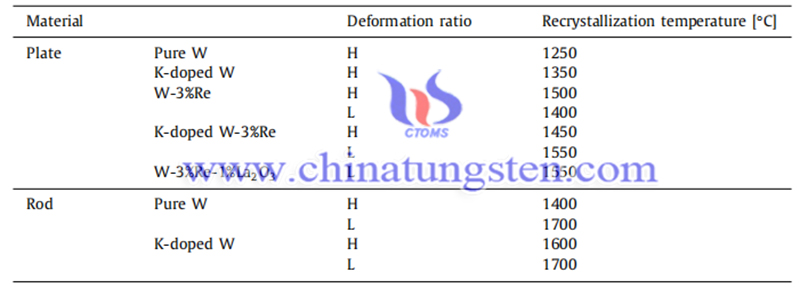

An increase in deformation ratio of modified tungsten materials can produce relatively rapid microstructural recovery and is generally less resistant to recrystallization. In the present study, materials with higher deformation ratios showed slightly lower recrystallization temperatures compared to materials with lower deformation ratios having the same major chemical composition.

These results indicate that K-doping, dispersion of La2O3 particles and Re-addition inhibit recrystallization of modified tungsten materials, which may be due to K-bubbles, La2O3 particles and solute Re impeding the movement of grain boundaries and dislocations. In addition, Re-addition reduces the hardness in the received state due to solid solution softening, while K-doping and dispersion of La2O3 particles increase the hardness.

In addition, K-doped W-3%Re (L) and W-3%Re-1%La2O3 (L) plates show a synergistic positive effect of Re-addition and second phase dispersion (K-doping and dispersion of La2O3 particles) on the inhibition of recrystallization. In contrast, only the K-doped W bars (L) show no positive effect of K-doping on the inhibition of recrystallization. This may be due to insufficient sintering and forging conditions to obtain undesired number density and size of K-bubbles.

In the case of sheet materials, grain growth during microstructure recovery and recrystallization was not significant except for pure W(H) sheets. The pure W(H) sheets showed significant grain growth at 1200-1300 °C and above 2000 °C, which may be attributed to primary and secondary recrystallization, respectively. The data scatter of grain size is relatively large at 1900-2000 °C. This may be due to the fact that important grain growth may start in this temperature range.

The other materials showed small grain growth during primary recrystallization. w-3%Re(H) and K-doped W-3%Re(H) plates showed slight grain growth during secondary recrystallization. In contrast, no significant grain growth occurred in the K-doped W(H) and W-3%Re-1%La2O3(L) plates. Based on these results, K-doping, dispersion of La2O3 particles and Re-addition have the ability to inhibit grain growth. In particular, for grain growth caused by secondary recrystallization at relatively high temperatures, K doping and dispersion of La2O3 particles are more effective than Re-addition.

It is known that most of the beneficial effects of second-phase dispersions occur at high temperatures, e.g., above half the melting temperature of the base material. For example, high-temperature creep deformation can be suppressed by the suppression of grain boundary sliding due to second-phase dispersion. Therefore, it is believed that K-doping and dispersion of La2O3 particles can be effective for phenomena occurring at relatively high temperatures compared to other modification methods, such as alloying. As an example, we believe that the inhibition of grain growth was observed in the present study.

Reference: Nogami S, Hasegawa A, Fukuda M, et al. Mechanical properties of tungsten: recent research on modified tungsten materials in Japan[J]. Journal of Nuclear Materials, 2021, 543: 152506.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com